This article is part of the This Week in PowerBites Library Series.

What you’ll learn:

- While wide-bandgap semiconductors continue to gain widespread acceptance, steady improvements in MOSFET technology make it apparent that plain old silicon remains relevant for many applications.

- Recent upgrades to the SAE's J3068 standard for vehicle-to-grid (V2G) interfaces have moved the technology much closer to a commercial reality.

- While all-electric airliners may be a decade or more away, several hybrid-electric aircraft are nearing commercial production and appear to have a shot at changing the economics of regional, short-haul, and air taxi services.

Updates to SAE's J3068 Standard Pave the Way for Interoperable V2G/V2X in EVs

Recent upgrades to the Society of Automotive Engineers' (SAE) SAE J3068 standard that defines the requirements for two-way power transfers for EVs have moved vehicle-to-grid (V2G) technology much closer to a practical commercial reality. Stay tuned for an in-depth feature about the standard and the engineering issues it raises for EV and EV charger designers. In the meanwhile, the article “EVs are One Step Closer to Becoming Roaming Grid Batteries,” published by Canary Media, provides an excellent introduction to the topic.

The story covers many of the basic concepts behind V2G and provides an overview of the updates to the SAE J3068 standard. In addition, there’s analysis of the standard by University of Delaware professor Willett Kempton, who explains why he feels that it represents "a practical, low-cost, and implementable way to turn every EV into a roaming grid battery.” Kempton also provides some insights into the technology and policy gaps that are holding V2G back from mainstream adoption.

Check out Electronic Design's Power Management home page for updates on V2G standards, technologies, and applications.

2,000-V SiC MOSFETs Offer Increased Power Density without Compromising Reliability

A new CoolSiC MOSFET 2,000-V series of silicon-carbide (SiC) power transistors from Infineon Technologies will be housed in the TO-247PLUS-4-HCC package to meet designers' demand for increased power density with high reliability under demanding high-voltage and switching-frequency conditions. The 2,000-V family is ideally suited for high DC-link systems with up to 1,500 V DC. Compared to 1,700-V SiC MOSFETs, the devices also provide a sufficiently high overvoltage margin for 1,500-VDC systems.

The CoolSiC MOSFETs deliver a benchmark gate-threshold voltage of 4.5 V and come equipped with a robust body diode for hard commutation. Due to the .XT connection technology, the components offer first-class thermal performance.

With low switching losses, the devices are well-suited for solar (e.g., string inverters) and energy storage systems, and electric-vehicle charging applications. The TO-247PLUS-4-HCC package, with a creepage distance of 14 mm and clearance distance of 5.4 mm, offers excellent moisture resistance.

In addition to the 2,000-V CoolSiC MOSFETs, Infineon will soon be launching a series of matching CoolSiC diodes in the third quarter of 2024. These diodes are particularly suitable for solar applications. A matching portfolio of gate drivers is also available.

The CoolSiC MOSFET 2,000-V product family is available now. Furthermore, the EVAL-COOLSIC-2KVHCC evaluation board can be used as a precise universal test platform to evaluate all CoolSiC MOSFETs and diodes. It’s also applicable to Infineon's EiceDRIVER Compact Single Channel Isolated Gate Driver 1ED31xx product family through double-pulse or continuous PWM operation. More information is available here.

Three-Phase Driver IC Boosts Battery Life for Cordless Power Tools and E-Mobility

Alpha and Omega Semiconductor Limited introduced the AOZ32063MQV gate driver for brushless DC (BLDC) motor applications. Available in a compact, 4- × 4-mm QFN-28L package, the highly integrated AOZ32063MQV is a three-phase driver IC that offers extended driving ability, programmable dead-time, and sleep-mode support for BLDC motor-control applications using < 60 Vin.

Such capabilities deliver high operation efficiency and low standby power consumption that can help greatly increase the battery life of cordless power tools and e-mobility applications. The AOZ32063MQV is also an optimal driver IC solution for three-phase BLDC motor drives.

The new driver IC features multiple advanced protection functions, including input undervoltage protection, short-circuit protection, overcurrent protection, and thermal shutdown. Equipped with a wide input voltage range from 5 to 60 V and supporting 0.8-A source and 1-A sink driving capability, the AOZ32063MQV also has a wide operating (−40 to +125°C) ambient temperature range and offers high-side 100% duty-cycle operation support.

"The AOZ32063MQV is capable of supporting the operation of two parallel MOSFETs delivering fast switching, efficiency, and advanced protection advantages that help to simplify and reduce BOM costs in today’s wide range of higher-power BLDC motor application designs,” said Armin Hsu, Sr. Marketing Manager for motor driver products at AOS.

Unit price for the AOZ32063MQV, available now, is $1.55 USD in 1,000-piece quantities.

App Note: Optocoupler-Based Compensation Improves Stability in Flyback Converters

A new application note published by Würth Elektronik,“Compensating the Feedback Loop of A Current-Controlled Flyback Converter with Optocoupler,” discusses using a DC-DC flyback converter to achieve greater stability and reliability in power-supply design. It might also be useful for designers who use optocouplers for galvanic isolation of the feedback path.

Applications include primary and auxiliary power supplies for home appliances, battery chargers for smartphones and tablets, as well as LED lighting. The app note also provides valuable assistance with power supplies for desktop and laptop computers, industrial power supplies and auxiliary supplies in motor drives, or for Power over Ethernet (PoE).

App note ANP113 explains in detail how the feedback loop can be compensated using a current-controlled flyback converter with optocoupler, and which aspects require special attention. The current transfer ratio (CTR) influences the control loop of the compensation circuit and therefore must be carefully considered in the design stage.

ANP113 places particular emphasis on design constraints imposed by the optocoupler parameters and on the related solutions. The validation results of a 30-W flyback converter prototype are also revealed.

The main topics include:

- Control-to-output transfer function of a current-mode flyback converter.

- Analysis and design of a type-2 compensator circuit with optocoupler.

- Impact of optocoupler CTR and parasitic capacitance in the system.

- How to achieve a fast transient response despite the optocoupler frequency limit.

- Analytical, simulation, and experimental results of a prototype.

Plug-and-Play SiC Gate Driver Facilitates Designing with High-Voltage SiC Power Modules

To help developers fast-track the development of SiC power applications, Microchip Technology released the 3.3-kV XIFM plug-and-play mSiC gate driver. It significantly reduces design and evaluation time of SiC-based inverters and other applications. The driver features proprietary Augmented Switching technology, which allows it to be preconfigured with custom-optimized settings that enable the module to work out-of-the-box with many of the company's most popular SiC power modules.

The XIFM digital gate driver is a compact solution that features digital control, an integrated power supply, and a robust fiber-optic interface that improves noise immunity. This gate driver has preconfigured “turn-on/off” gate-drive profiles that are tailored to optimize module performance. Each of its these profiles embody the results of complex development work involved in designing, testing, and qualifying a gate-driver circuit design that’s been fine-tuned for the power module and its application.

In addition to its 10.2-kV primary-to-secondary reinforced isolation, the XFIM driver offers built-in monitoring and protection functions including temperature and DC-link monitoring, Undervoltage lockout (UVLO), overvoltage lockout (OVLO), short-circuit/overcurrent protection (DESAT), and negative temperature coefficient (NTC). The gate driver also complies with EN 50155, a key specification for railway applications.

The 3.3 kV XIFM plug-and-play mSiC gate driver is now available. For more information about Microchip’s SiC portfolio, click here or here.

Automotive-Grade MDmesh Superjunction MOSFETs Prove Silicon Still Matters

STMicroelectronics' automotive-grade 600/650-V superjunction MOSFETs in the STPOWER MDmesh DM9 AG series deliver high efficiency and ruggedness for onboard chargers (OBCs) and DC-DC converter applications in both hard- and soft-switching topologies.

With outstanding RDS(on) per die area and minimal gate charge, the silicon-based devices combine low energy losses with outstanding switching performance, setting a new benchmark figure of merit. The devices are fabricated using ST's latest MDmesh DM9 technology, which produces a tighter gate-source threshold voltage (VGS(th)) spread that results in sharper switching for lower turn-on and turn-off losses.

In addition, body-diode reverse recovery is improved, leveraging a new optimized process that also increases the MOSFETs’ overall ruggedness. The diode’s low reverse-recovery charge (Qrr) and fast recovery time (trr) suit the MDmesh DM9 AG series for phase-shift zero-voltage switching topologies that demand the utmost efficiency.

The family offers a selection of through-hole and surface-mount packages that help designers achieve a compact form factor with high power density and system reliability. The TO-247 LL (long-lead) is a through-hole option that eases design-in and leverages proven assembly processes. Among the surface-mount packages, the H2PAK-2 (2 leads) and H2PAK-7 (7 leads) are optimized for bottom-side cooling with thermal substrates or PCBs featuring thermal vias or other enhancement. HU3PAK and ACEPACK SMIT topside-cooled surface-mount packages are also available.

The first device in the new STPOWER MDmesh DM9 AG series is the STH60N099DM9-2AG, a 27-A AEC-Q101-qualified, N-channel 600-V device in H2PAK-2, with 76-mΩ typical RDS(on). ST will expand the family to provide a full range of devices, covering a broad range of current ratings and RDS(on) from 23 to 150 mΩ.

The STH60N099DM9-2AG is available now from the ST eStore, from $4.98.

High-Efficiency, 1200-V Full-Bridge MOSFET Modules Target Solar Inverter, EV Charging Apps

A new family of full-bridge power modules from SemiQ is based on its QSiC 1200-V SiC MOSFETs. The modules deliver near zero switching loss, significantly improving efficiency and reducing heat dissipation, as well as enabling the use of smaller heatsinks.

The compact modules also offer a straightforward thermal interface that can help simplify the design of solar inverters, EV chargers, and other high-power applications. In solar inverter applications, SemiQ's technology empowers designers to achieve greater efficiency—reaching as high as 98%—and more compact designs.

With a high breakdown voltage exceeding 1400 V, the QSiC modules in full-bridge configurations withstand high-temperature operation at Tj = 175°C with minimal RDS(on) shift across the entire temperature spectrum. Crafted from high-performance ceramics, SemiQ’s modules achieve exceptional performance levels, increased power density, and more compact designs, especially in high-frequency and high-power environments frequently found in solar inverters, drives and chargers for electric vehicles, DC-DC converters, and power supplies.

To guarantee a stable gate-threshold voltage and premium gate-oxide quality for each module, SemiQ conducts gate burn-in testing at the wafer level. In addition to the burn-in test, which contributes to mitigating extrinsic failure rates, various stress tests—including gate stress, high-temperature reverse-bias (HTRB) drain stress, and high humidity, high voltage, high temperature (H3TRB)—are employed to attain the necessary automotive- and industrial-grade quality standards. The devices also offer extended short-circuit ratings, and all parts have undergone testing surpassing 1,400 V.

SemiQ’s new 1200-V modules in full-bridge packages are available in 20-, 40-, and 80-mΩ SiC MOSFETs categories. The table below shows the part numbers.

For specifications and to request samples or volume pricing, visit the company’s site. Download the datasheets for parts GCMX020A120B2H1P, GCMX040A120B2H1P, GCMX080A120B2H1P, GCMX020A120B3H1P, and GCMX040A120B3H1P from the QSiC family of 1200-V MOSFET modules in half-bridge configurations, or start at the product page here.

Miniature Resettable Thermal Cutoff (TCO) Devices Feature Higher Current-Carrying Capabilities

Bourns Inc.’s latest miniature resettable thermal cutoff (TCO) device series, also known as mini-breakers, are designed to control abnormal, excessive current virtually instantaneously, up to rated limits. The Model NX Series offers higher current-carrying capabilities combined with a very low-profile package at a height of 0.94 mm and body width of 2.8 mm.

Such features make this series an ideal overtemperature and overcurrent protection solution for lithium-polymer and prismatic cells in high energy density, smaller batteries such as next-generation notebook PC and tablet battery cells, as well as handheld and wearable electronics.

The Model NX Series has current capabilities from 12 to 20 A at 60°C and is available with or without welding projections. Providing design flexibility for a wide range of application environments, these TCO devices are available with four trip temperature options of 77, 82, 85, and 90°C—all of which operate within a ±5°C tolerance. The devices are also designed with a high-rated corrosion-resistant bimetal mechanism that delivers enhanced endurance in humid environments compared to standard TCO devices.

The Model NX Series, available now, is RoHS-compliant, halogen-free, and UL/TÜV-recognized. For additional product information, click here.

Advanced GaN Power Stages and DC-DC Modules Push the Limits of Power Design and Density

Texas Instruments recently unveiled two new power-conversion device portfolios: a family of GaN power stages, and what the company said are the smallest 1.5-W, isolated DC-DC modules. Both product families were created to help engineers achieve more power in smaller spaces, providing the highest power density at a lower cost.

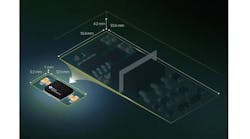

The UCC33420-Q1 and UCC33420 1.5-W isolated DC-DC modules with integrated transformers, also the most power-dense devices, according to TI, are intended to help engineers shrink the isolated bias power-supply size in automotive and industrial systems by over 89%.

The new modules use the company’s next-generation integrated transformer technology, which eliminates the need for an external transformer in a bias supply design. The technology enables engineers to shrink solution size by more than 89% and reduce height by up to 75%, while cutting bill of materials by half compared to discrete solutions.

The modules deliver over 8X higher power density and the highest output power and isolation capability (3 kV) for automotive and industrial systems in a 4- × 5-mm no-lead (VSON) package. TI’s UCC33420-Q1 and UCC33420 enable designers to easily meet stringent electromagnetic-interference (EMI) requirements, such as Comité International Spécial des Perturbations Radioélectriques (CISPR) 32 and 25, with fewer components and a simple filter design.

Preproduction quantities of the UCC33420 and UCC33420-Q1 modules are available now for purchase, with versions of these devices expected to be available in second quarter of 2024. To learn more about the benefits of TI’s 1.5-W isolated DC-DC modules, read the technical article, “How a new isolated DC/DC module can help solve power-density challenges.”

GaN Power Stages

TI’s new 100-V integrated gallium-nitride (GaN) LMG2100R044 and LMG3100R017 power stages feature thermally enhanced, dual-side cooled package technology to simplify thermal designs. They achieve the highest power density in mid-voltage applications, reducing solution size by 40% or more. Boasting a power density of 1.5 kW/in.3, their lower output capacitance and gate-drive losses can deliver up to 50% lower switching losses than a comparable silicon-based design.

Production quantities of the LMG2100R044 and LMG3100R017 100-V GaN power stages are available now for purchase. For additional product information, click here.

To learn more about the benefits of TI’s 100V GaN power stages for mid-voltage applications, read the technical article, “4 mid-voltage applications where GaN will transform electronic designs.”

Hybrid-Electric Aircraft: Quickly Moving from Concept to Commercial Reality

Surf Air Mobility Inc. and Electra.aero Inc. (“Electra”) have joined forces to use Electra’s hybrid-electric short takeoff and landing (eSTOL) to make affordable, sustainable, and easily accessible regional air travel to many of the U.S.’s nearly 5,000 public use airports.

The 9-passenger, 200-mph production aircraft, based on a successfully-tested prototype, will enable Surf Air to provide economical on-demand air mobility services. The 90 unit pre-order from Surf Air adds to 2,000+ aircraft pre-orders and options already placed by over 35 key operators.

An 80% scale technology demonstrator equipped with Electra's blown-lift STOL system has proven the basic feasibility of their technologies. As shown in the video above, the technology demonstrator took to the skies for the first time for an all-electric test flight on November 11, 2023 and a hybrid-electric flight on November 19. Based on initial tests of its prototype, Electra estimates its production craft will be able to safely operate from airfields as short as 300 feet.

Development of a prototype of the production aircraft is underway. The production prototype's batteries will be supplemented by a 600-kW electric turbogenerator propulsion system, manufactured by Safran Helicopter Engines, which will provide enhanced power for takeoff and serve as a range extender.

Additional information about Electra's eSTOL airliner, and other hybrid-electric aircraft that are expected to enter service by the end of 2025 can be found in the article “Hybrid-Electric Aircraft are Moving Swiftly from Concept to Commercial Reality.”

Read more articles in the This Week in PowerBites Library Series.