Market-research company IHS predicts the fast-evolving wearable-product market will be worth $30 billion in revenues and 210 million units by 2018. Devices worn on the wrist, such as fitness activity trackers like Misfit or Misfit Shine, smartwatches like the Pebble and Omate X, or products that may create a new category altogether like wristbands that authenticate a user’s identity through their electrocardiogram (ECG), will probably constitute a majority of shipments.

Still, there are a number of other imaginative use cases for the taking, such as T-shirts with embedded displays that potentially could show a video running on the wearer’s smartphone. Or new applications that fully grasp the possibilities presented by wearables as part of the Internet of Things (IoT), linking devices to cloud computing.

Bluetooth Low Energy

Low-power wireless connectivity holds the key to further advances in wearables. Its implementation impacts wearables of all kinds, from relatively simple and single-sensor-based devices such as activity trackers, to high-end products that integrate data from many environmental sensors (e.g., a pair of snow goggles with a built-in heads-up display for GPS/mapping and distance/speed indication).

This file type includes high resolution graphics and schematics when applicable.

Bluetooth low-energy (LE), now branded as Bluetooth Smart by the Bluetooth SIG (Special Interest Group), becomes a significant piece in the jigsaw puzzle of enabling technologies for wearables. While Bluetooth LE as a wireless standard isn’t without competition, it’s well placed to become the preferred connectivity.

As a low-power technology, Bluetooth LE will significantly contribute to the ability of wearable products to work for weeks, months or even years from a small coin-cell battery. In fact, Bluetooth LE has already being integrated into the latest smartphones and tablets. All of today’s wearable products are “appcessory” (application accessory) products that connect via Bluetooth to an application running on a smartphone or tablet, utilizing the device’s user interface or display. Typically, that app will connect to the Internet so that the wearable can become categorized as an IoT device.

Devices that employ Bluetooth LE features incorporate Bluetooth Core Specification Version 4.0 (or higher). Bluetooth LE 4.0 enables small amounts of data to be sent in bursts, thanks to a unique packet format with low latency (connection setup and data transfer can be achieved as quickly as 3ms) that allows for ultra-low peak, average, and idle-mode power consumption.

For reference, a product that implements only the low-energy feature is known as a single-mode device. A product that implements both the low-energy feature and the original Bluetooth “Classic” mode with Enhanced Data Rate (EDR) is known as a dual-mode device, or “Smart Ready.” According to the Bluetooth SIG, more than 90% of Bluetooth-enabled smartphones, including iOS-, Android-, and Windows-based models, are expected to be Smart Ready by 2018.

Low-Power MCUs

Crucial to wearable product design is the use of small and efficient (performance/power) low-power microcontrollers. An essential ingredient is an “always-on, always-aware” processor that handles motion sensors, such as accelerometers or gyroscopes, or environmental sensors like pressure- or temperature-sensing components.

In multiple sensor designs, the processor performs the “fusion” of data from the sensors to deliver better and more accurate information to a user. As importantly, this approach reduces the amount of data transmitted up into to the cloud. Designers often turn to processors like the ARM Cortex-M3 in these scenarios.

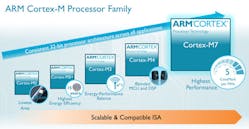

The ARM Cortex-M series of 32-bit processor cores range in performance from the ultra-low-power Cortex-M0+ to the top-of the-range Cortex-M7 processor, which incorporates high-efficiency signal-processing features for digital signal control, as well as accelerated single-instruction, multiple-data (SIMD) operation. Many existing wearable products have used the highly flexible ARM Cortex-M3, which features low power consumption while optimizing performance and code density. An example of a Cortex-M3-based MCU solution is STMicroelectonics’ STM32 MCU family, which has been deployed in wearable products such as the Fitbit Flex activity tracker and the Pebble smartwatch.

MCUs based on the Cortex-M0 and Cortex-M0+ not only enable ultra-low power coupled with performance, but also offer size and integration advantages. One example is the Freescale Kinetis KL03 MCU, which is claimed as the smallest ARM-powered MCU. Based on a Cortex-M0+ processor running at 48 MHz, the device comes in a 1.6- by 2.0-mm2 wafer-level chip-scale package (CSP). According to Freescale, the KL03 consumes 35% less printed-circuit-board (PCB) area, yet delivers 60% more general-purpose input/output (GPIO) than competing MCUs.

Instruction-set support is one differentiating factor between Cortex-M processors. The Cortex-M0/Cortex-M0+ has a reduced set of instructions that diminishes the complexity (and size) of the core. The richer instruction set of the Cortex-M3 and Cortex-M4, and now Cortex-M7, better suits more complex data processing (Fig. 1). The Cortex-M4 also offers digital-signal-processing (DSP) instructions and an optional single-precision floating-point unit (FPU). The Cortex-M7 provides 5 CoreMark/MHz and 2.14 DMIPS/MHz for high-end MCUs, which suits it for systems that previously needed an MCU plus separate DSP.

Minimizing power consumption is absolutely critical in wearable products. On that front, two architecture-defined sleep modes deliver static power figures of less than 0.7 μW/MHz for the Cortex-M3 and -M4.

MCU/Bluetooth Combo

As discussed, combining Cortex-M-based MCUs with a low-power single- (Bluetooth LE) or dual-mode Bluetooth module can create tiny, yet powerful, wearable products An alternative approach, however, could deliver greater integration and target more complex designs—a system-on-a-chip (SoC) device that combines a Cortex-M processor core and Bluetooth LE transceiver functionality.

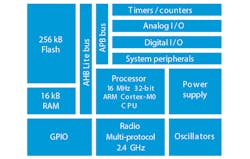

One example of this approach is the nRF51822 from Nordic Semiconductor (Fig. 2), which is a highly flexible, multi-protocol SoC that suits Bluetooth LE and 2.4-GHz ultra-low-power wireless applications. The nRF51822 is built around a 32-bit Cortex-M0 core with 256-kbyte flash and 16-kbyte RAM. The embedded 2.4-GHz transceiver supports Bluetooth LE version 4.0, in addition to proprietary 2.4-GHz operation.

A second example is Dialog Semiconductor’s SmartBond DA14580, a single-mode Bluetooth LE version 4.0/4.1 SoC that integrates the Cortex-M0 processor. The DA14580 draws only 4.9 mA during transmission and reception, and less than 600 nA at 3 V in deep sleep mode. The device, which can also run from voltages as low as 0.9 V, will suit energy-harvesting schemes in completely autonomous systems. Available in a wafer-level CSP measuring 2.5 by 2.5 by 0.5 mm, the DA14580 requires only five external components and can operate from a single coin cell, enabling its use in the smallest of wearables.

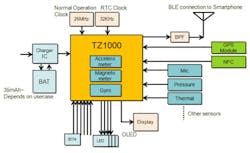

And at the higher end are Toshiba’s TZ1001MBG and TZ1011MBG application processors (Fig. 3), which integrate the Cortex-M4 processor core, a Bluetooth LE controller plus RF circuitry, as well as flash memory and sensors. While the TZ1001MBG features an accelerometer, the TZ1011MBG is expected to integrate a magnetometer and gyroscope in addition to an accelerometer. Use of the Cortex-M4 with DSP and FPU allows for combined data from multiple sensors that are both internal and external to the chip. The processors also integrate a high-resolution ADC to convert signals from external devices, such as pulse wave and electrocardiogram sensors, into digital data.

Development Platform

To aid in rapid prototyping, product development, and the creation of wearable innovation opportunities, it’s essential to have easy access to the latest technology. In that regard, ARM mbed (mbed.org) is a key open-source platform for the development of Cortex-M-based products and applications, offering development kits and boards along with free online tools and open source libraries.

The mbed platform enables developers to mix and match components such as MCUs, radios and sensors, and provides software stacks for wireless connectivity via Bluetooth LE, Wi-Fi, and cellular. In addition, it also simplifies integration with services based on the Internet Protocol (IP), providing application programming interfaces (APIs) for cloud services.

The mbed software development kit (SDK), licensed under the Apache 2.0 free software license, is an open-source C/C++ software platform. Powerful enough to build complex projects, the SDK also provides a hardware abstraction layer built on the low-level ARM Cortex Microcontroller Software Interface Standard (CMSIS) APIs. These enable consistent and simple software interfaces to the processor for interface peripherals, real-time operating systems (RTOSs), and middleware, simplifying software reuse and reducing the learning curve for new developers.

Based on the standard ARM professional C/C++ compiler, the Web-based mbed compiler is an online integrated development environment (IDE) that’s free to use with hardware that implements the mbed hardware development kit (HDK). In addition, the compiler supports full export to different toolchains. The mbed component database has reusable libraries for a range of hardware that includes sensors, plus middleware and IoT services.

The mbed hardware development kit (HDK) provides full MCU subsystem design files and firmware for building development boards and custom products. Development boards based on the HDK are usually the quickest way to get started with the mbed platform, which include Cortex-M-based boards from leading semiconductor companies such as Freescale, NXP, ST and Nordic Semiconductor.

For instance, one key development kit for Bluetooth LE is Nordic’s nRF51822-mKIT (Fig. 4). Based on the aforementioned nRF51822 SoC, it’s the first mbed development platform specifically aimed at Bluetooth LE applications. The kit is fully compatible with the mbed Bluetooth LE APIs, simplifying use of the protocol stack, and a range of mbed software libraries. The combination of the nRF51822-mKIT and Bluetooth LE APIs via the ARM mbed ecosystem exemplifies a platform that enables a quick and easy start to wearable product development.

User Interface and App Development

In terms of fast software user-interface development for wearables, the Koru OS from Korulab offers a user interface that looks much like the Android OS. However, it’s highly optimized in terms of code density and is targeted at wearables that run on MCU-powered hardware. The memory footprint for core system code is as small as 118 kbytes, yet it can also handle 60-frame/s performance on a Cortex-M4 processor. There’s kernel support for OSs such as Android, FreeRTOS, NetBSD, and Linux, and graphics engine support including OpenGL ES, Open VG, and Framebuffer.

The Koru UI framework facilitates software coding with tools that can automatically generate all of the necessary graphical assets. The OS is also highly scalable for different size screens for various wearable form factors, such as a watch, amulet, or armband.

For developers looking to develop a wearable product within a few days or perhaps even hours, all that’s required is the development of a mobile app based on MetaWear, which started life as a Kickstarter project. This is a production-ready platform based on an SoC that combines a Cortex-M0-based MCU with a Bluetooth LE transceiver, together with sensors such as an accelerometer and temperature sensor.

MetaWear firmware comes pre-loaded on the platform and exposes Bluetooth services and characteristics for all peripherals and sensors. MetaWear Android or iOS APIs can be downloaded and even sample iOS and Android apps are available. In addition, 3D CAD designs targeting enclosures for MetaWear hardware are available for generation on a 3D printer.

Conclusion

It’s rather clear that the wide variety of ARM Cortex-M-based hardware, along with the ARM and mbed software, provides an array of development building blocks that hastens the creation of wearable and accessory products. On top of that, Google’s AndroidWear operating system, announced at the Google I/O conference in June 2014, is being brought into the market on Cortex-A processors in devices like the Moto360 watch.

This file type includes high resolution graphics and schematics when applicable.

The ubiquity of high-performance and low-power ARM-based solutions for mobile and wearable markets means that developers needn’t remain with one supplier of ARM-based MCUs and/or Bluetooth LE controller/RF chips or modules, or indeed sensors.

With its processors in tow, ARM’s focus has turned to assembling an ecosystem of additional system building blocks, centered on enabling customers to deploy (Internet-connected) systems as efficiently and quickly as possible. On the software side, there’s a range of operating systems, compilers, middleware, code libraries, and other tools that support Cortex-M processors via the ARM mbed ecosystem. This rich collection of resources makes it possible and perhaps surprisingly easy to design a wearable device or appcessory featuring low-energy Bluetooth connectivity and ARM Cortex processing capabilities within weeks or even days.

Diya Soubra is a CPU product marketing manager for the Cortex-M3 processor and IoT subsystems at ARM. He has 20 years of experience in the semiconductor industry, during which he held various positions in engineering, product marketing, and business management.