This file type includes high resolution graphics and schematics when applicable.

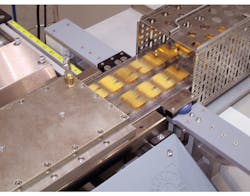

Efficient and accurate handling of semiconductor and microelectronic components often is a main determinant in overall quality and cost of assembly, particularly in high-production environments. Therefore, choice of magazine-handling equipment could turn into a make-or-break decision.

The main advantages of magazine handlers are threefold: cutting back on manual-labor costs, reduced contamination, and increased product quality due to avoidance of human interference or error. Applying the best magazine handler design only serves to dramatically amplify those advantages.

The five most important criteria when selecting a magazine handler are:

1. Design Simplicity

The relatively simple design of magazine handlers helps boost system reliability and productivity, and eases integration. “Simplicity of design guarantees ease of operation and manufacturing robustness,” says Alexander Komposch, Head of Package and Process Development, Infineon Technologies NA (Morgan Hill, Calif.). Komposch’s division is a high-volume manufacturer of RF power transistors used in cell-phone base stations.

“In the past, we have worked with highly sophisticated designers who are top-notch in wire bonding, a critical capability in the manufacture of RF transistor products,” continues Komposch. “Yet, when it came to developing a magazine handler, they tended to over-design what should be a fairly simple process, overcomplicating it to the point that the handler was unreliable and had to be removed from the production line after a short time.”

The magazine handlers standardized by Infineon were designed, engineered, and manufactured by Martek Automation (Murrieta, Calif), a leading developer of automated material-handling and assembly equipment.

2. Low Maintenance

Many OEMs incorporating magazine handlers into their systems insist that the equipment requires little maintenance. Not only do they want to avoid unnecessary maintenance trips to the field, but they demand that their primary systems, such as wire bonding equipment, not suffer downtime due to magazine-handler maintenance requirements.

“The only part on our magazine handlers that requires replacement is the pinch roller, which is a simple silicon wheel,” says Komposch. “This is important to us, because in 24/7 production you don’t want to have downtime, and the reliability of our magazine handler is essential to the avoidance of that problem.”

3. Consistency of Alignment

Alignments are critical when adding magazine handlers to a microelectronics production line. Unfortunately, some handlers are built using designs and materials based on cost savings rather than ruggedness. Such systems can become misaligned when simply brushed by an operator.

“I believe that magazine handlers with welded steel frames, such as the Martek models, provide stability that protects alignment,” says Komposch. “This is very important because magazine handlers are not typically anchored; it is free-standing equipment that maintains alignment by standing on its own weight. That ensures it will remain in-line with a conveyor system of any type of production equipment.”

4. Capacity

The capacity of a magazine handler to carry the optimum number of magazines correlates directly to throughput and productivity. On top of that, the ability to carry non-standard magazine sizes and accommodate special carriers or materials can be acutely important when choosing a magazine handler.

“We are able to have up to eight magazines on the input and output sides, where as most competitors’ handlers were able to deliver only four,” says Komposch. “Also, the handlers we use have the ability of carry two rows, which also improves the speed of throughput.”

5. Flexibility

OEMs need, and highly value, a magazine handler’s ability to detect the next magazine and Auer boat (or other carrier), as well as detect the location of an empty slot. Auer boats are standardized carriers used to convey multiple microelectronic components into a dispenser and unload the parts after processing. A single magazine can hold multiple Auer Boats. These carriers get their name as a result of the collaboration of the company Auer Precision with Intel, Fairchild, Motorola, and others to develop an industry-standard process carrier.

“There are no rules about how many Auer boats you need to have in one magazine, how many magazines you have to have in it, which positions you need to have,” says Komposch. “It is a very simple mechanism that always finds the next slot for providing you an Auer boat or an empty slot to receive an Auer boat. So, it’s a very independent, simple design that minimizes the amount of moving parts needed to provide you with the exact thing you need. It always has an Auer boat available for the processing equipment, when needed.”

This file type includes high resolution graphics and schematics when applicable.

Ed Sullivan, a Hermosa Beach, Calif.-based writer, has researched and written about high technologies, healthcare, finance, and real estate for over 25 years.

For more information, check out Martek Automation’s (38415 Innovation Court, Murrieta, Calif. 92562) website at www.martekautomation.com. Or contact them via email: [email protected], phone: (951) 304-0541, or fax:(909) 496-0582.