This file type includes high-resolution graphics and schematics when applicable.

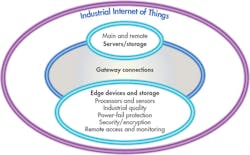

A shift is underway in data storage for Industrial IoT (IIoT) designs—away from traditional approaches, and toward full, integrated solutions dedicated to storing, computing, controlling, connecting, and protecting critical information. These solutions address needs that go well beyond those of the Internet of Things (IoT). They’re designed specifically for IIoT applications, in which system reliability and data security requirements are absolute.

What distinguishes solid-state disks (SSDs) for IoT from those for IIoT? The short answer: A lot! Let’s examine them.

The IoT world is rapidly evolving. Smart thermostats introduced five or so years ago that focused mainstream attention on IoT are now a mere small segment of consumer-focused applications. And while those IoT uses for the home and office were developing, the industrial embedded community was hard at work developing solutions for the more extreme, mission-critical applications of internet-connected devices.

The types of SSDs commonly found in consumer IoT applications are simple drives that lack the performance, endurance, and reliability of industrial-grade SSDs. A telling comparison would be how consumer-grade SSDs are just fine for desktop and laptop computers. But if you try to convince a seasoned engineer they can work reliably in an embedded or enterprise storage system, you’ll hear a big, fat “No!”

In addition, enterprise-class SSDs built for multi-threading don’t fit the IIoT mold either, as they may exceed power or cost restrictions. And often the higher capacities and high IOPS, which add to higher power requirements and cost overruns, simply aren’t needed for IIoT applications.

Because IIoT endpoints are usually found in harsh and/or remote environments, the SSDs used here must be able to support extreme temperatures and often support extreme vibration and shock. They also must be built with a “set it and forget it” purpose and last longer than your typical SSD. That’s because the applications and the critical data they collect and store simply cannot be compromised. There’s far more at stake in IIoT data collection and storage applications than for basic IoT.

The bottom line is this: Using IIoT SSDs provides a tailored fit for the requirements, a much better total cost of ownership, and a longer life for the IIoT design.

SSDs for IIoT demand a range of features that grows with each generation:

Small footprint: Compact form factors like M.2 and Slim SATA will make it possible to easily integrate the SSD in IIoT applications of diverse sizes.

Industrial-grade durability: The IIoT SSD would include high endurance and a rugged industrial design to mitigate effects of shock, vibration, and temperature (–40 to 85°C), thus assuring the drive’s reliability and more importantly, critical data.

Optimal capacities and interfaces: Like in many embedded applications, the IIoT doesn’t place a premium on high capacities, but on the optimum number of bytes for the design. Minimal-capacity SSDs draw less power and are less expensive. Furthermore, support for SATA or PCI Express enables high bandwidth for the applications and leverages industry-standard interfaces.

Low power: The benefit of reduced power consumption isn’t limited to cost. Low-power IIoT SSDs also mean greater durability and less cooling/ventilation so that the drive can be used in space-constrained designs.

Data security: Given our world of ever-increasing sinister data breaches, unbreakable security in any IIoT ecosystem is essential. Security starts at the edge, so it’s important to add built-in security to the IIoT devices themselves. This includes device authentication and data encryption to protect the data collected at the edge from unauthorized use or tampering. IIoT SSDs should ideally provide pre-boot authentication and hardware-based Advanced Encryption Standard (AES) protection to offer data-at-rest security.

Platform-agnostic design: Few things can tank a movement faster than it being based on a proprietary architecture. Therefore, this emerging generation of IIoT-focused SSDs needs to be platform-agnostic for easy deployment in new or legacy applications.

Network-ready: Whether the device is using RS-232/485, CAN, USB, or Ethernet, IIoT data storage is useless unless it’s accessible. Available network connectivity options include WWAN, WLAN, WPAN, 3G/4G cellular, and satellite communication.

Remote monitoring: When IIoT SSDs are out on the network edge, it’s not practical—indeed, sometimes impossible—to conduct on-site monitoring. Remote-monitoring software (already available for existing industrial-embedded SSDs) will be critical in assuring performance and reliability of Industrial-IoT storage.

The above may seem like a long wish list for IIoT engineers, but the items on it are closer to here-and-now solutions than they may seem. A new generation of IIoT SSDs is on the horizon. Vendors such as Virtium are designing SSDs from the ground up specifically for industrial applications. And they’ll be on the market sooner than later.

In summary, IoT and IIoT storage solutions are very different species. Off-the-shelf SSDs are fine for thermostats, refrigerators, and other household IoT uses, but no one can expect an oil rig, factory, or other industrial environment to trust its crucial data to SSDs made for consumer applications. Moreover, enterprise SSDs are overkill and cost-prohibitive.

In the near future, the industry will see the shift toward highly integrated, IIoT-purposed SSDs accelerate, and the distinction between them and ill-suited, consumer-grade drives will be all the more striking.