Low-cost, fast, non-volatile storage has been the Holy Grail long before magnetic core memory provided this functionality—at least that’s been the case for a while. The current crop of memory technologies is dominated by static and dynamic RAM and flash memory. Technologies like MRAM and FRAM have risen, but none has yet to unseat current technologies.

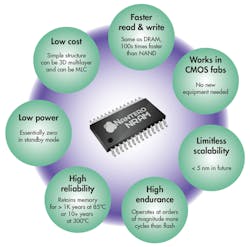

Nantero’s NRAM may be the one. It scales well and is fast for reads and writes. I spoke with Greg Schmergel, Co-Founder, CEO, and President of Nantero, about the company’s technology.

Wong: Clearly, the race has been on to develop a new generation of memory to replace DRAM and flash as they approach their end of life. What is NRAM and how does this stack up with the other solutions being developed?

This file type includes high resolution graphics and schematics when applicable.

Schmergel: Nantero’s NRAM is a new generation of super-fast, ultra-high-density memory that can enable a variety of exciting new features and products in both consumer and enterprise electronics. What differentiates NRAM is that it is based on carbon nanotubes (CNTs), has already been installed in multiple production CMOS fabs, and is currently being designed into innovative new electronic products that require increased storage, lower power consumption, high speed, reliability, and high endurance. We currently have more than a dozen major corporate partners actively working on NRAM, and we are now beginning the next phase toward commercialization, which will bring Nantero’s NRAM into volume production and change the course of electronics innovation for decades to come.

Wong: What are the technical advantages of NRAM?

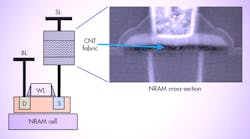

Schmergel: NRAM is as fast as and denser than DRAM; non-volatile like flash; has substantially lower power consumption than DRAM in standby mode or flash in active mode; and is highly resistant to environmental forces (heat, cold, magnetism, radiation). The write energy per bit is 160 times lower than NAND flash, and being that it is nonvolatile, does not require refreshing like DRAM (Fig. 1). Given the high switching speed, NRAM is compatible with existing interfaces, such as DDR4 or earlier versions of DDR, as well as SRAM or flash interfaces. This makes NRAM the ideal solution for the next generation of memory technology for both standalone and embedded applications.

Wong: What is the advantage of using carbon nanotubes? I thought carbon nanotubes were just found in the research lab today?

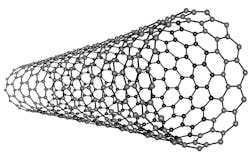

Schmergel: As shown in Figure 2, carbon nanotubes are considered to be one of the strongest materials known to man. With one CNT being just 1/50,000th the diameter of a human hair, these nanoscale cylinders are 50 times stronger than steel, half the density of aluminum, and have better thermal and electrical conductivity properties than any other material scientists are aware of today.

As a pioneer in nanotechnology, Nantero is the first and only company to actively develop semiconductor products using this material in production CMOS fabs. This breakthrough achievement is now protected as part of the company’s carbon-nanotube electronics patent portfolio, which consists of more than 175 U.S. patents issued to date and more than 200 patents pending.

Wong: Does NRAM require new processes and tools?

Schmergel: It doesn’t, which is another key advantage of NRAM. We’ve installed it in multiple production fabs and it not only uses the same tools and processes, but can also run on the existing production lines that currently run DRAM or flash, or in a logic foundry. With NRAM, there is no additional capital expenditure and it can be easily spin-coated on wafers using existing coat tools, and patterned using existing lithography and etch tools. This will enable manufacturers to quickly and cost-effectively migrate to a new generation of memory that is both high speed and nonvolatile.

Wong: From a technology perspective, how does NRAM work?

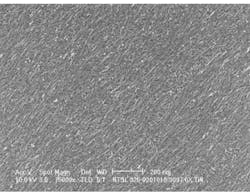

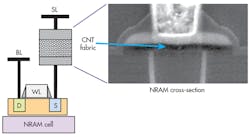

Schmergel: NRAM is based on forming a film of CNTs that are deposited onto a standard silicon substrate that contains an underlying cell select device and array lines (typically transistors or diodes) that interface the NRAM switch. Figure 3 is a SEM image of the deposited film (or fabric) of nanotubes that can be either touching or slightly separated depending on their position.

The NRAM acts as a resistive non-volatile random-access memory (NVRAM), and can be placed in two or more resistive modes depending on the resistive state of the CNT fabric. When the CNTs are not in contact, the resistance state of the fabric is high and represents a "0" state (Fig. 4). When the CNTs are brought into contact, the resistance state of the fabric is low and represents a "1" state. Figure 5 shows a full NRAM cell.

NRAM has unique attributes that enable it to also be made as a monolithic 3D memory.

Wong: Sounds great, but how about the cost?

Schmergel: In the last two years alone, the cost of the CNT material on a per-chip basis for memory has been reduced by more than 10X. This means the CNT material cost is now negligible with respect to chip cost, making the value proposition of CNT memory more compelling than ever.

Wong: What kinds of devices will use NRAM?

Schmergel: Because NRAM is as fast as DRAM and non-volatile like flash, it provides substantial opportunities for new designs and architectures, and even new devices. We expect to see NRAM in a range of products, including consumer devices such as PCs, laptops, smartphones, and tablets, as well as enterprise systems such as networking hardware, storage arrays, and numerous other applications. It is also ideal for government and military usage, and high-temperature and other high-reliability applications.

Wong: You just wrapped up a new funding round. Tell us a little about that and what you have planned next?

Schmergel: Yes, Nantero just closed a $31.5 million Series E financing round, which included new investors and participation from existing investors Charles River Ventures, Draper Fisher Jurvetson, Globespan Capital Partners, and Harris & Harris Group. This substantially oversubscribed round highlights Nantero’s ongoing success in delivering a new generation of super-fast, ultra-high-density memory that can enable a variety of exciting new features and products for both consumer and enterprise applications. We intend to use the new funds to continue the acceleration of NRAM as the leading next-generation memory for both storage-class memory and as a replacement for flash and DRAM.

This file type includes high resolution graphics and schematics when applicable.

The availability of a new generation of memory that is hundreds of times faster than NAND, delivers terabits of storage capacity, and consumes very little power has the potential to change the future of electronics. Nantero’s NRAM has all of these characteristics and we are excited to enter the next phase of commercialization.