Some see the development world as being enamored by 32-bit architectures but 8- and 16-bit platforms have been around a long time and they are not going away. Microchip Technology is one of the companies that remains in the forefront of 8-bit development.

I recently talked with Steve Drehobl, Microchip’s MCU8 Division Vice President. He highlights Microchip’s 8-bit innovation including the integration of core-independent and intelligent-analog peripherals with their popular 8-bit PIC architecture.

Wong: The embedded marketplace is maturing, yet 8-bit MCUs continue to be used in a large number of designs. Where do you still see innovation and market need for 8-bit MCUs?

Drehobl: Today’s cost-sensitive embedded design environment requires a paradigm shift away from the traditional “Bytes and Megahertz” approach. Every embedded system contains a combination of common functions, such as power conversion, motor drive, sensor and human interface, and signal generation. Microchip enables these deterministic functions with configurable, integrated peripherals on our 8-bit MCUs.

Integrating several system functions onto a single MCU using the “Bytes and Megahertz” approach can limit flexibility. Each additional function requires an increased amount of RAM to store variables, more Flash to execute code and higher processing speeds to ensure that system timing is within specification. As a result, this approach requires a larger, more expensive microcontroller with less flexibility and higher power consumption than necessary.

Microchip is taking a different approach. By crafting the PIC® MCU portfolio to suit the evolving needs of our customer base, we can support a wide variety of functions using a “hybrid approach.” Today’s 8-bit PIC MCUs include on-chip peripherals that can operate without constant interaction from the CPU and that have the ability to communicate directly with other peripherals to create flexible feedback loops. These “core independent” blocks of configurable hardware intelligence require little to no code, consume very little power and are much smaller than the RAM and Flash needed to implement a given function within the core. Additionally, many simultaneous functions can be enabled in a single PIC MCU. This leads to flexible, power-efficient 8-bit PIC MCU designs with the capability to perform the same tasks as a much larger and more expensive device.

Core Independent Peripherals enable 8-bit PIC Microcontrollers to retain their class-leading low-power performance while meeting or exceeding our end customers’ design requirements for functionality and performance.

Wong: What are the advantages of a Core Independent Peripheral-based approach, as opposed to implementing a function using a higher-performance MCU?

Drehobl: The advantages are many, but the most significant are the increase in execution speed and the decrease in software and development time required to implement a given function.

When you implement a function in hardware, you are doing so with the lowest possible latency. However, hardware-only solutions limit design flexibility. We’ve taken the best of both worlds by using configurable, dynamically interconnected peripherals that keep latency to a minimum while retaining the flexibility of a traditional software-only approach. Our 8-bit PIC MCUs can implement functions that were previously unthinkable in the 8-bit space—including applications such as Peak Current Mode power-supply control in peripheral hardware, with a faster and more deterministic response than interrupt-based control.

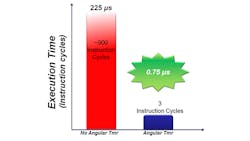

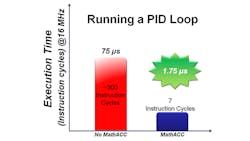

The reduction in instruction cycles required to implement a function leads to significant performance enhancement. For a great example, we can look into the details of our integrated Angular Timer peripheral. It dynamically measures the elapsed time for periodic angular or sinusoidal events, regardless of the speed or rate of acceleration of the event’s source. This makes the Angular Timer perfect for many applications, including motor control, where the MCU needs to trigger an event, such as a phase angle interrupt, at a certain point in the rotor’s travel. Doing this in software can tie up precious CPU resources, not to mention require large amounts of code to monitor and service such an event. Peripherals like these help users free up on-chip memory and reduce CPU demand by as much as 98% (Fig. 1). Additionally, peripherals such as our Math Accelerator can enable PID control loops with an order-of-magnitude reduction in code size, when compared to a software-only approach (Fig. 2).

Core Independent Peripherals also allow engineers to partition each system task for easier function management. Providing them with the ability to perfect a segment of an application without the concern that it will impact others helps reduce their design cycle time.

With larger amounts of free CPU instruction cycles and RAM/Flash memory available, a design engineer can now focus on integrating other parts of his or her application into the MCU. Higher levels of system integration enable our customers to design end products that are smaller, lower power, easier to service and more reliable.

Wong: Why would an engineer start a new design with an 8-bit MCU, rather than a 16- or 32-bit MCU?

Drehobl: History has shown that a “one size” MCU does not fit all applications. Our customers are focused on building systems to solve their design problems. Their primary goals are to increase revenue and profit while reducing risk of failure. Our goal is to provide the right solution to solve the customer’s design problem. To that end, Microchip has large and successful PIC MCU portfolios in 8-, 16-, and 32-bit architectures.

The 8-bit PIC MCUs excel in their simplicity and flexibility. They offer a relative ease of design that can significantly reduce hardware development cycle time. Significant improvements in time to market can also be realized that directly contribute to increased revenues for our customers. The reduction in code size resulting from the use of Core Independent Peripherals can also lessen the amount of software testing and development needed. This reduction in development cost can be significant, while a tandem benefit of reduced “failure points” can be experienced.

Our tools make it easy to get started. The free MPLAB Code Configurator (MCC) plugin, the latest addition to our suite of MPLAB X Integrated Development Environment (IDE) tools, provides a simple graphical interface to initialize and configure PIC MCUs. With MCC, an engineer can get a product configured to his/her application without opening a product data sheet.

Wong: Doesn’t it make sense to “future proof” your design with a 32-bit architecture?

Drehobl: Our recommendation is to select the “best-fit” architecture for any project, based on needs and requirements that can be identified at the design’s outset. Doing so will help keep both hardware and software development cost to a minimum. Often, an 8-bit PIC MCU will help reduce overall system hardware cost, and the functions enabled in on-chip hardware can massively reduce software efforts over the life of a design.

In the event that a design needs to be migrated to a 16-bit or 32-bit PIC MCU, we make this process a simple one through the use of a consistent, unified toolset. We start with our main building block—the tried-and-true MPLAB X IDE—and complement it with our MPLAB XC compilers and our large portfolio of hardware development tools. Additionally, we offer the MPLAB Harmony software framework for 32-bit PIC32 MCUs, and the MPLAB Code Configurator for 8 and 16-bit PIC MCUs, to simplify product configuration and setup across our more than 1,000-strong MCU portfolio.

It’s impossible to determine what the future will hold. If the market shifts to an entirely different set of functional requirements, a complete system redesign will be required. Selecting a 32-bit architecture at the outset of a design for the purposes of “future proofing” will not mitigate a market shift. In fact, doing so can cause designers to “optimize” in unproductive areas, which can add the burden of unnecessary cost, power consumption and software complexity to an already-constrained design team.

Some of our competitors recommend “future proofing” with a single 32-bit MCU architecture; often, because they have abandoned development efforts on their 8- and 16-bit product lines. We don’t see a need for our customers to restrict their architecture choices.

Wong: Are there any other reasons why your customers continue to choose 8-bit MCUs for new designs?

Drehobl: Simply put, we are evolving our 8-bit MCU portfolio to fit the needs of the market and our customers. As the Internet of Things spawns new and exciting embedded systems, we focus on being the MCU of choice for the design of “Things.” To this end, 8-bit PIC microcontrollers are designed to be a simple, “best-fit” option for a wide variety of modern embedded applications. We focus on providing four key pillars of embedded design to make our customers’ designs as easy as possible: operating-voltage range, power consumption, robustness and product flexibility are all extremely important to our customers.

We have several hundred 8-bit MCUs in our portfolio that give designers the choice of selecting an operating voltage at any level between 1.8V and 5V. With the lowest Active and SLEEP current consumption in the industry, 8-bit PIC MCUs can do more work and last longer on a given amount of energy than other competing solutions.

We also use special design and test methodologies to ensure that PIC MCUs achieve the highest EMI and EMC performance standards. Flexible pin routing features help engineers design their systems for better noise rejection. With PIC MCUs, designers can add flexible intelligence to the harshest environments.

The performance and flexibility added by our Core Independent Peripherals gives our customers the tools they need to evolve their applications. The total package gives them the freedom to innovate, without the limitations that traditional MCU architectures impose.