Download this article in .PDF format

One thing about analog integrated circuits (ICs) is they tend to stick around. The low-dropout (LDO) regulator first came to widespread attention in 1977, when National Semiconductor’s Bob Dobkin published an article about the adjustable version in Electronic Design magazine. Back then, digital technology was pretty basic: Intel’s 8085 was the microprocessor du jour, with 6500 transistors, a screaming 3.0-MHz clock, and less processing power than a modern-day coffee pot.

Microprocessors have come a long way since 1977. The 8085 is long gone—Intel’s latest Xeon boasts over 7 billion transistors and a 5-GHz clock—but many decades-old LDO designs are still in production. The LDO plays a key role in the newest wearable and portable electronic devices, such as fitness bands, patient monitoring equipment, and smart watches.

Why is the venerable LDO finding a home in these applications? After all, an LDO is pretty inefficient compared to a switching regulator. Well, it’s inexpensive and reliable. Furthermore, it takes up little board space and offers low-noise performance—two key factors for wearable applications.

Wearable devices have to cram a lot of functionality into a very small volume. Not only that, a battery occupies a large proportion of the available space (see above). Compared to a buck regulator that requires bulky capacitors, diodes, and inductors, the LDO needs few or no external components and consumes little board area.

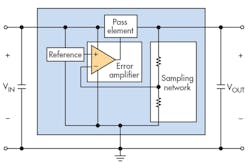

Figure 1 above shows the block diagram of a typical LDO, consisting of the pass element, voltage reference, error amplifier, and a sampling network. Externally, an input capacitor filters input transients and upstream noise; an output capacitor ensures output voltage stability and helps with ripple rejection. The ratio of the resistors in the sampling network determines the output voltage, so the sampling network for an adjustable LDO is also external.

How can we minimize the size of this basic arrangement?Minimizing LDO Circuit Size

• Select a Fixed-Voltage LDO

A fixed LDO saves space because the sampling network is now internal. Although SMD resistors are now extremely small (the smallest 0201 package measures only 0.6 × 0.3 mm), that’s still not zero. Plus, of course, they need to be routed and placed on the board.

A fixed-voltage LDO offers two other advantages. First, it saves cost. Agreed, it’s only a cent or two per LDO, but manufacturing and inventory costs are also associated with an increased part count.

Second, a fixed LDO improves performance. The figures quoted in the datasheet apply to the whole LDO, including the internal sampling network. If the datasheet specifies 1% accuracy over temperature, such as with the TPS7A3725, then expect that tolerance. An adjustable LDO design needs to factor in the external resistor network’s tolerance and performance over temperature, and tighter tolerances increase cost.

Developing an accurate figure for the performance of an adjustable LDO isn’t a trivial task. TI’s application note AN-1378 discusses this topic in detail.

Does choosing a fixed device limit the voltage options? Originally, fixed LDOs were available in only a couple of flavors, but the choices have expanded dramatically, especially in the low-voltage space. TI’s LP5907 250-mA LDO, for example, comes in 18 versions with outputs from 1.2 to 4.5 V.

• Eliminate the Capacitors

The other components in Fig. 1 are the input and output capacitors. Can we eliminate either of these?

As mentioned earlier, input capacitors help improve line transients, attenuate upstream noise, help stabilize the input rail if there are parasitics, or filter upstream inductance.

A wearable or portable application, though, gets its power from a battery, a very stable source that’s typically located adjacent to the regulator. This proximity means that any load transients at the output of the LDO don’t result in large input-voltage deviations. Removing the input capacitor can save on both space and cost, assuming that the other application requirements are met.

The last external component to consider is the output capacitor. Benefits of an output capacitor include improved ripple rejection and load transient response, but its main role has traditionally been to ensure stability. The output capacitor’s equivalent series resistance (ESR) is used to modify the open-loop response of the LDO itself to counteract phase shift that would otherwise lead to oscillation at higher frequencies.

Some LDOs, such as the TLV713 single-channel and TLV716 dual-channel families, are designed for a stable open-loop response and don’t require an output capacitor. Removing the output cap certainly ensures a smaller design, but loses the filtering benefits. Therefore, make sure the capless design meets the application requirements.

• Choose the LDO that Gives the Smallest Overall Solution

At the risk of stating the obvious, the smallest LDO that meets the performance requirements isn’t necessarily the LDO that minimizes the overall size of the solution. The TLV733P, for example, is a 300-mA LDO. There are 10 output voltages between 1 and 3.3 V, and it’s available in a 1- × 1-mm X2SON package. Although a smaller device might be available, the TLV713 requires no capacitors, so the total solution size remains 1 mm × 1 mm.

LDOs in Low-Noise Applications

The other LDO advantage we talked about is superior noise performance. Many of the features in wearable and portable devices are extremely sensitive to noise. Tablets and smartphone cameras, for example, use CMOS image sensors that contain noisy power supply directly affects the quality of the image.

What are some the important specifications to consider when selecting a low-noise LDO?

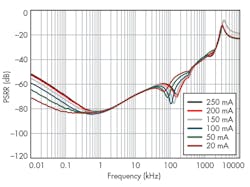

The power-supply rejection ratio (PSRR) is a measure of how well the regulator rejects noise from the power supply appearing at its input. It’s basically a comparison of the output ripple and the input ripple over the frequency range of interest for the application. PSRR is expressed in decibels (dB)—the higher the number, the better the rejection. Figure 2 shows the PSRR for the LP5907 250-mA ultra-low-noise LDO.

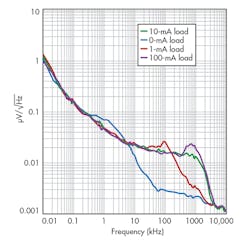

The other important noise parameter is the intrinsic noise generated by the regulator itself. This appears at the output of the LDO and is characterized by a spectral-noise-density graph (Fig. 3), which shows how the noise, expressed in µV/√Hz varies over frequency.

The noise of the internal voltage reference, amplified by the error amplifier, is a dominant source of LDO output noise. Thus, the LP5907 includes a first-order, low-pass RC noise filter between the voltage reference and the error amplifier.

Note that although the LP5907 also comes in 18 varieties and is available in a X2SON package, it’s not a capacitor-free device like the TLV733P we discussed earlier. The LP5907 is optimized for low-noise design and consequently requires a 1-µF capacitor on the output for stable operation. For maximum layout flexibility in space-constrained applications, though, the output capacitor can be placed up to 10 cm away from the LDO.

As with any high-performance design, it’s important to follow the PCB layout recommendations in the datasheet to ensure stability and maintain the noise performance of the part.

LDO Design Example: Bluetooth Controller

A low-noise power supply is vital for many wireless applications that contain low-frequency analog signals from audio transceivers or analog sensors. These are susceptible to noise coupling from high-speed signals in adjacent traces in the board or to RFI or EMI radiation.

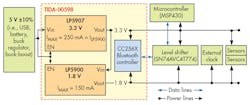

Figure 4 shows the block diagram of a power-management design for a Bluetooth Low Energy (BLE) application. In this design, an LP5907 low-noise LDO filters any line ripple and generates the base system power, a regulated 3 V. It also supplies the input voltage to an LP5900 that provides up to 150 mA at 1.8 V to power lower-voltage devices. Cascading the two devices increases the current required from the LP5907, but allows the LP5900 to operate more efficiently.

The CC256x Bluetooth controller supports the BLE Host Controller Interface (HCI) mode, plus Bluetooth Basic Rate (BR) and Enhanced Date Rate (EDR) protocols.

The host controller is a member of TI’s MSP430 low-power 16- or 32-bit microcontroller family. Input power is 5 V from a battery, USB connection, or another source.

Both LDOs require output capacitors: 0.47 µF for the LP5900 and 1 µF for the LP5907. In both cases, the capacitors must have an ESR of 5 to 500 mΩ to ensure stability.

Conclusion

Low-dropout regulators are the preferred solution in battery-powered portable and wearable applications, where small size or low-noise operation are key requirements. Fixed-voltage LDOs can accommodate numerous different supply voltages; many are stable without external input or output capacitors. However, the lowest-noise designs require one or both components, so careful device selection is critical.