Download this article in PDF format.

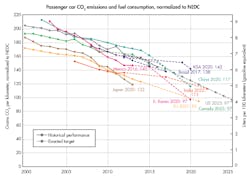

Automakers across the U.S., Europe, China, and Korea must achieve CO2 emissions reduction to comply with the current legislation (Fig. 1), which means most EU OEM hybrids will feature 48-V systems by 2020. Upscaling to a 48-V automotive architecture can help carmakers more successfully wrangle with power efficiency and CO2 emissions.

A new trend within the automotive industry is the “dual-voltage system.” Each manufacturer is quickly developing its own solutions, spurred on by the chance to reduce wiring harness weight and losses while meeting CO2 emission goals. Note that electrified vehicles not only include electric and hybrid vehicles, but combustion vehicles, too. Power-electronics advances in the latter are further extending their automation and safety features, among others.

1. The EU 2021 CO2 emission target of 95 g/km becomes the most stringent numerical standard to date, surpassing the US 2025 target of 97 g/km in NEDC terms. (Courtesy of ICCT)

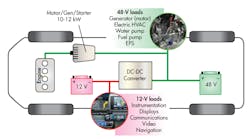

Solutions on the drawing board include the 48-V board net, which would power loads such as air-conditioning compressors, start-stop systems, and electric superchargers/turbos. Also, a 12-V board net alternative will power the lighting, infotainment, and audio systems (Fig. 2).

The technology for that isn’t here quite yet, though. For the near future, a 48-V/12-V dual-battery system becomes the best option before total adoption of a sole 48-V power system, where switches and sensors can be safely used at higher voltages. “At least in Europe, it might take up to 10 years to start seeing 12-V system components converted into 48-V components,” says Ed Kohler, Intersil’s Senior Marketing Manager.

2. The 48-V system supports heavier loads. (Courtesy of Intersil)

Ushering in Bidirectional DC-DCs

Stepping up and down will require safe and efficient transfer of power using dc-dc converters. In this case, bidirectional dc-dc controllers will help to link both voltage systems.

When studying the new bidirectional converter architectures aimed at automotive applications, several trends are emerging that reflect the move toward 48/12-V systems and the increased importance of bidirectional dc-dc controllers. Tier 1 suppliers and OEMs in the automotive industry already include dual voltages in their designs.

For instance, Audi’s next SQ8 will have a 48-V system that will be used to drive an Integrated Starter Generator, which will regenerate the energy to quickly reload a 0.9-kWh lithium-ion battery. Increasing voltage will also help efficiently deliver high-in-demand technologies like stop-start and regenerative braking.

Paving the Way for 48-V Systems

Two products in particular stand out as examples of the latest trends permeating the automotive space:

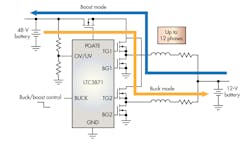

Intersil’s ISL78226 is a six-phase bidirectional PWM controller that delivers up to 3.75 kW in either direction at greater than 95% efficiency. This automotive-grade AEC-Q100 qualified product integrates PMBus system control to support functional safety requirements (ISO 26262). If a fault condition is detected, depending on the level of the fault condition, the ISL78226 provides warning flags, auto/start, hiccup, or latch-off functions in response.

The ISL78226 doesn’t include FET drivers; therefore, the controller could be placed away from the FETs and avoid the associated noisy switching nodes without negatively impacting the FET gate-drive loops. This system partition allows for optimal EMI, efficiency, and regulation accuracy.

3. A bidirectional dc-dc converter can be used to perform power conversions between the dual 48-V/12-V system. (Courtesy of Intersil)

Because balance current is extremely valuable, the ISL78226 includes internal phase-to-phase current balancing and ISET/ISHARE pins for current balancing between devices to equalize stress on the power stages. With each stage delivering 30 to 60 A of average current, small mismatches can cause large temperature variations and uneven stresses that can lead to reduced operating life and reliability concerns. Intersil offers a 2.5-kW six-phase bidirectional evaluation board (ISL78226EVAL1Z) (Fig. 3) and GUI for users to modify any of the control settings of the IC and to monitor fault flags.

Linear Technology’s LTC3871 (Fig. 4) is a bidirectional PolyPhase synchronous two-phase buck or boost controller that maintains up to 97% efficiency. The controller, which meets AEC-Q100 automotive specifications, is designed with intrinsic safety that’s in accordance with ISO-26262. Four control loops, two for current and two for voltage, enable control of voltage and current on either 48- or 12-V systems.

4. The LTC3871 controller features programmable overvoltage and undervoltage thresholds. (Courtesy of Linear Technology)

For output loads that demand high current, multiple LTC3871s can be daisy-chained to run out of phase to provide more output current without increasing input and output voltage ripple. Up to 3 kW can be supplied with a maximum of 12 phases when daisy-chained to run simultaneously out of phase with respect to each other. Linear Tech also offers a demo board; the DC2348A-A operates with two LTC3871 devices, each with four phases.

Conclusion

Audi, BMW, Daimler, Porsche, and Volkswagen have proposed the LV 148 standard to define a 48-V power supply, but the full adoption of 48-V systems might be accelerated by the creation of an international 48-V standard. Creating such a standard would require a collaborative effort from all members of the automotive industry to define the electrical architecture, including power-supply functions and interfaces.

In the meantime, dual-voltage subsystems offer great potential in reducing CO2 emissions. They will also generate demand for highly efficient bidirectional converters that are certified to function in automotive applications.