It had to happen. Power over Ethernet (PoE), once viewed as simply an alternative to powering every electronic device in a worker’s cubicle with inefficient “wall-wart” power adapters, but limited to trivial power levels, has matured into a technology capable of delivering 50 and 60 W or more via the same CAT-5 cables that bring the Internet to those cubicles. Driving the technology are applications that few envisioned a decade ago (see “A Long Way from CAT-5 Powered VoIP”). As a result, new ICs are emerging from Akros Silicon, Linear Technology, Maxim Integrated, STMicroelectronics, Texas Instruments, and others.

PoE History

PoE, or more formally, IEEE standard 802.3, evolved circa 2003 as an effort to replace analog, twisted-pair private branch exchange (PBX) telephone routing systems in business offices with Ethernet-based telephones. It could be powered via the same CAT-5 cables that carried digital voice and data between Internet switches or routers and an office full of single-user voice phones.

This file type includes high resolution graphics and schematics when applicable.

PoE first appeared as a subset of the standard, designated 802.3af. Specs indicated that two of the wires in each CAT-5 cable were to deliver full-duplex data communication; the other two provided 48-V dc power, with power available at the switch limited to 13 W maximum. The standard also had a protocol by which a “powered device” (PD) at the user end of the cable could interact with the “power sourcing equipment” (PSE) back at the router.

The 13-W limit was a precaution. At the time, there was no empirical data about what heating effects would accompany the IR drops across bundles comprising hundreds of very long cables, tucked into troughs snaking long distances through hard-to-access areas of occupied buildings. There was also concern about possible arcing when unplugging power-carrying RJ45 jacks.

At the time it was introduced, PoE was hailed as a solution for a range of possible mixed data-and-power applications beyond office phones. Possibilities included Wi-Fi hotspots, security cameras, and even card-locks for doors.

However, that 13-W limit almost doomed IEEE 802.3 at the start. In the early part of the 21st century, video was looming as the next great advance in data phones, and 13 W was just not enough to power the phone itself, plus any video capabilities. The crude solution would have been to power the new videophones with ac adapters, but most baseboard power plugs in workers’ cubes were already bristling with wall warts for computers, monitors, and personal electronics. It would be expensive to re-wire existing facilities for more ac power. PoE also came with a bonus—it didn’t require licensed, union electricians to install low-voltage (defined as 48-V dc and below) wiring.

Thus, in 2009, the IEEE updated the PoE standard 802.3af to 802.3at, otherwise known as “PoE-plus,” or “PoE+.” The new version increased the voltage and current requirements to supply 25.5 W of power.

Basics of PoE

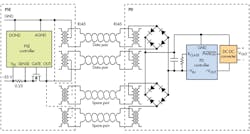

In PoE nomenclature, the device that provides power to the network is known as a PSE, or power-sourcing equipment, while the device that draws power from the network is called a PD, or powered device (see the figure).

PSEs are built into either of two types of Ethernet distribution gear: endpoints (typically network switches or routers) that send both data and power; and midspans that inject power on selected ports, but pass through conventional Ethernet traffic from non-PoE endpoints on all ports.

As originally conceived, PoE could use either the data pairs or the spare pairs in an Ethernet cable to carry 48 V dc from the PSE in an endpoint switch or midspan hub to the PD appliance at the other end of the cable. Data pairs were powered via a center tap, while spare pairs were simply paralleled. The sense of the dc voltage didn’t matter, thanks to a diode bridge in the PD ahead of the PD controller chip.

Originally, it was never anticipated that every device at the far end of an Ethernet cable support PoE. Therefore, it became necessary to establish a handshake mechanism to ensure that a PSE would not apply power unless a PD was on the other end. It was also desirable that the PD have some way to relay to the PSE its maximum power requirements. The first part of this handshake was accomplished by requiring the presence of a 25-kΩ resistor across the PD chip’s input.

To check for this resistor’s presence on the other end of a CAT-5 cable, the PSE would first apply a series of voltages, incremented in 1-V steps at 20-ms intervals, and use the resulting currents to verify the presence and value of a terminating resistor. This part of the handshake was the “discovery” phase.

To verify compatibility between the power capacity of the PSE and the needs of the PD appliance, the initial standard provided for an optional “classification” phase. Here, the PSE would briefly assert a 15.5- to 20-V pulse on the pair, to which the PD would respond either by temporarily placing a load on the line or by doing nothing. Having a resistor, but not responding to the pulse, was tantamount to self-identifying the PD as “Class 0,” and the PSE would supply up to 12.94 W.

To keep the cost of power supplies down, other PD classes signaled that they needed less than the maximum Class 1 demands, to 3.84 W, and Class 2 would need no more than 6.94 W. Class 3 PDs, under 902.3af, signaled that they needed the full 12.94 W.

Powering the Load

Once the PD was discovered and classified, the PSE could apply unregulated 48 to 50 Vdc, with current limited as necessary, to the CAT-5 cable. A standard Ethernet cable contains four twisted pairs, though only two are needed to carry data back and forth. Under basic PoE, powering is an either/or situation—but only one pair can be used at a time. This limitation was imposed to enable the use of either new endpoint routers with built-in PoE, or in midspan-bridge-powered legacy systems. In the latter case, midspans would only power the spare pairs, while new endpoint equipment could power either pair.

Powering the spare pairs in basic PoE requires paralleling of pins 4 and 5 for one side of the dc supply and paralleling of pins 7 and 8 for the other side. When using the data pairs, the PSE applies dc power to the center tap of each isolation transformer so that pins 3 and 6 supply one side of the dc and pins 1 and 2 supply the other. At the PD, center taps on each transformer recover data-pair power.

More Power

Predictably, once the original 802.3af scheme was up and working, there came an immediate demand for higher power levels. Not only was 802.3af underpowered for phone systems with video displays, design engineers immediately envisaged a host of new applications. With more power, security cameras could include pan, tilt, and zoom motors. Wi-Fi hotspots could cover wider areas. Security-card readers could self-power the door latches they protected. Almost immediately, the task force began work on IEEE 802.3at, which soon acquired the informal name “PoE+,” pronounced “PoE-Plus.”

Part of the task force’s job was to decide whether the additional power would involve simply increasing the maximum current rating or paralleling the spare pairs with the data pairs. A more challenging part involved expanding the classification scheme so that PDs could negotiate on-the-fly with the PSE for more or less power.

After considerable testing, it was found that CAT5 cable and RJ45 connectors could, in fact, handle more current and that it would be acceptable to use both sets of twisted pairs. So, one could have it both ways—more current and four active pairs. Unfortunately for midspan makers, though, if no continuity exists through the spare pairs, they can supply only half as much power as an endpoint switch.

In absolute terms, IEEE802.3at established PoE Plus’ maximum power capacity, based on 48 V, at 25.5 W at the load.

Beyond Just Pushing More Current

The above situation unfolded in 2007. Now, at least three makers of PoE PD and PSE semiconductor devices—Linear Technology, Texas Instruments, and Akros Silicon—offer the ability to provide up to 90 W to PDs, while accommodating earlier hardware running at its original ratings. Higher-powered PSEs from one source may not necessarily be compatible with higher-powered PDs from other sources, but the operational fundamentals derived from the 802.3 standards. Thus, the new PDs look like standard PDs to legacy PSEs, and new PSEs are not going to be confused by legacy PDs.

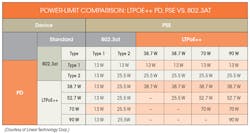

One example of the new generation of PoE devices comes from Linear Tech, with PSEs and PDs that it designates “LTPoE++” (“plus-plus”). Essentially, says the company, “LTPoE++ is a proprietary high-power standard that uses a single CAT-5e Ethernet cable to provide four different PD power levels: 38.7W, 52.7W, 70W, and 90W. These LTPoE++ power levels allow external components in the power path, such as MOSFETs, transformers and dc-dc converters, to be sized accordingly so that designs can be optimized both in terms of cost and efficiency. LTPoE++ is interoperable and backward-compatible with both IEEE 802.af PoE and 802.3at PoE+ standards, so LTPoE++, PoE+ and PoE devices can all be mixed and matched. LTPoE++ has a simple plug-n-play nature, so PSE and PD controllers can seamlessly connect, classify, and communicate with one another. With a complete end-to-end solution that requires no additional code.”

The concepts are described in greater detail in the company’s Journal of Analog Innovation.1 The treatise specifically compares LTPoE++ and IEEE802.2at (see the table).

Define What’s Prime

Like television’s “Star Fleet,” LTPoE++ has a “Prime Directive.” Actually, it has two of them: “Do not turn on devices that shouldn’t be turned on,” and “Do turn on things that should be turned on.”

Linear Tech’s article elaborates: “LTPoE++ PSEs can differentiate between an LTPoE++ PD and all other types of IEEE-compliant PDs, allowing LTPoE++ PSEs to remain compliant and interoperable with existing equipment.” More explicitly, that means:

• Conventional Type-1 PSEs will power all Type-1, Type-2, and LTPoE++ PDs with up to 13 W.

• Conventional Type-2 PSEs will power Type-1 PDs with up to 13 W and provide 25.5 W to Type-2 and LTPoE++ PDs.

• When connected to traditional Type-1 and -2 PSEs, LTPoE++, PDs can power up. However, their functionality is limited by current available from the PSE.

• LTPoE++ PSEs will power Type-1, Type-2, and LTPoE++ PDs. The latter are powered to the designed limit of the LTPoE++ PSE.

• When a LTPoE++ PD is identified, it will only be powered up if the PSE power rating meets or exceeds the requested PD power. For example, a 52.7-W LTPoE++ PSE can power either a 38.7- or 52.7-W PD.

Texas Instruments’ Universal Power over Ethernet (UPOE) solution, the TPS2378, is an IEEE 802.3at-compliant, Type-2 PD controller. TPS2378 supports high-power auxiliary adapters and provides startup control for the dc-dc converter. Two of them in a dual configuration can support four-pair operation at 51 W.

UPoE comes in two basic forms. One is based on the Link Layer Discovery Protocol (LLDP), which uses the Ethernet data path. The other form is forced using circuit hardware only. In both forms, the PSE proceeds by detecting, classifying, and ramping up voltage to one pair set according to the IEEE 802.3at standard. The method used at the PD (LLDP or forced) determines how to apply the operating voltage to the second pair set.

A TI app note titled “Dual TPS2378 PD for 51-W High Power-Four Pair PoE”2 presents a typical application. Describing the reference design, TI says a high-power solution meets the basic criteria below:

• Current sharing between both pair sets provides at least 51 W available at the PD power interface. Inadequate current sharing might result in port turn-off, erratic behavior in the PSE or PD, or other negative results. Such erratic behavior might occur when current-limiting kicked in, or when the PD couldn’t supply sufficient input voltage to the pair set carrying the higher current. Alternatively, data transformer core saturation might result in inadequate current sharing. (This would be something to watch out for during product development. If it occurs, higher-current data transformers might be required, according to the note.)

• No overheating in the PD circuitry.

• A high efficiency dc-dc converter is required to maximize the power available to the load.

The TI note also discusses the importance of PD efficiency and current sharing, noting that, “The maximum ensured PD input power is 51 W with the PD input voltage as low as 42.5 V because of the cable impedance excluding the effect of current imbalance between pairs. As a consequence, the PD output power is limited by its efficiency.”

This file type includes high resolution graphics and schematics when applicable.

Ensuring reliable system-level operation requires a worst-case PD efficiency analysis. The worst-case efficiency includes the input bridge, the PD front-end return switch, any additional series diode, the PoE data transformers, and the efficiency of the dc-dc converter stage.

With passive current sharing, any impedance difference through each power feed and return impacts the current imbalance between each pair set. Passive current sharing requires that the PSE provide power through a single cable, and from a common voltage source, to minimize the impedance difference.

In some cases, TI notes that the use of a standard or Schottky bridge with negative temperature coefficient impairs sharing when there’s a short Ethernet link segment. To minimize this effect, diode characteristics must match with good temperature matching along with good printed-circuit-board thermal management.

References:

- Journal of Analog Innovation, July 2011, http://cds.linear.com/docs/en/lt-journal/LTJournal-V21N2-01-df-LTPoE__Heath_Stewart.pdf

- “Dual TPS2378 PD for 51-W High Power-Four Pair PoE,” Texas Instruments, Nov. 2013, http://www.ti.com/lit/an/slva625/slva625.pdf