Machine-to-machine (M2M) connectivity is on the rise, and as demand increases for connectivity of “things” anywhere, product developers are looking to add wireless functionality to a variety of devices. From connected cars, home appliances, healthcare, utilities and a wide range of other industries, the possibilities for M2M are endless.

Developers interested in adding wireless connectivity to their products are not necessarily wireless experts. For example, a home appliance manufacturer may not be proficient in antenna design. They may not be familiar with the details of a particular wireless standard. Or they may not be aware of FCC/IC certification requirements. This lack of wireless expertise could be a significant challenge for some developers, so in order for them to get to market quickly, they can look to affordable solutions that are easy to integrate and require the least amount of ramp-up.

There are basically two options for developers when adding wireless capability to a product. They can do their own chip-on-board (COB) solution or they can use a wireless module. Due to the significant effort involved in a COB solution, developers who lack wireless expertise often choose a module solution or hire a design house to do the development. The design house may then choose to do a COB solution or use a module.

If a developer decides to go with a module solution, it’s essential to establish a partnership with a module manufacturer that can provide the wireless expertise and services to support the module. Many module manufactures are now offering WLAN modules specifically targeting the M2M market. Ubiquitous, WLAN is an excellent choice for M2M applications requiring short-haul wireless communication.

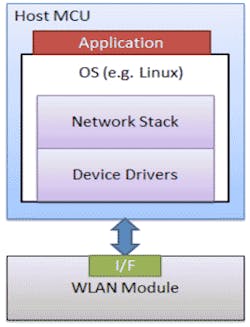

Generally, there are two types of WLAN modules available to developers: modules without the network stack and modules with the network stack. Fig. 1 (below) is an example of how a module without the network stack is integrated into a product. It shows the WLAN module providing the radio interface and the host MCU running the application, OS, network stack, and device drivers. This solution requires a fairly powerful host MCU. It also requires the developer to port the device driver to its OS, which could be time-consuming and overwhelming for some developers. While this may give the most flexibility, for developers looking to get to market quicker, this may not be the right solution.

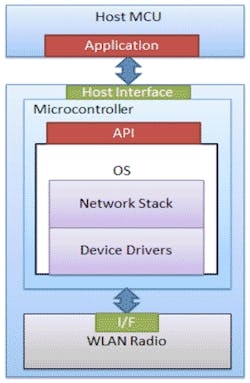

Fig. 2 (below) is an example of how a WLAN module with the network stack included is integrated into a product. By moving the network stack into the module, network processing is offloaded from the host MCU. Therefore, the need for a powerful host MCU is eliminated. An API (Application Programming Interface) is then added on top of the network stack. The API abstracts the complexities of WLAN from the user, making integration easier. Eliminating the need for a powerful MCU and providing developers with an easy-to-use API makes this type of module very suitable for M2M developers. The main drawback with this approach is the added cost on the module.

One such WLAN module with network stack is currently under development by Taiyo Yuden. Soon to be released, this module will be enabled by Marvell’s 88MC200 system-on-chip (SoC) microcontroller and 88W8787 WLAN SoC.

Ferdie Brillantes is a Wireless Module Field Applications Engineer at Taiyo Yuden (U.S.A.) Inc. He holds a BSEE from the University of Illinois at Chicago, an MSEE from Illinois Institute of Technology, and has over 20 years of experience in Software, Systems and Hardware Engineering.