This file type includes high-resolution graphics and schematics when applicable.

I live in New Jersey, and we exited hurricane season not too long ago. Hurricanes bring rain, flooding, and power losses. So upon hearing the predictions of the latest hurricane to hit the NJ coast, I started to wonder about my basement sump pump and considered protecting it with an uninterruptible power supply (UPS).

I had a UPS for my computer rated at 1200 W and 2000 VA, but it’s intended to run a computer system long enough for it to gracefully shut down. In my case, I was hoping to run the sump pump, as it cycles on and off, for a few hours to give me time to set up a backup generator. I had three questions to answer:

1. Would the startup current of the pump damage the UPS?

2. Would the steady-state power of the pump overload the UPS?

3. How long would the UPS operate my pump before the batteries were discharged?

To make these measurements, I turned to a power analyzer. In this case, I used a Keysight PA2201A IntegraVision Power Analyzer, which is an ideal tool for this job (Fig. 1).

Measuring Startup Current

To measure startup current, I needed to make a simple single-shot measurement of the current flowing from the ac line into the pump. As this was a single-shot measurement, I could have turned to a scope. However, I would have needed current probes and differential probes to measure the ac line voltage. A power analyzer is a better tool, since they’re designed to make ac power measurements.

While most power analyzers can directly measure voltage and current without the need for special probes, they typically can’t make single-shot measurements. But the IntegraVision Power Analyzer provided this single-shot-triggered measurement, and can measure current directly (up to 100 A peak) and floating voltages (up to 1000 Vac).

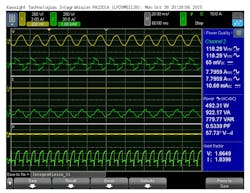

I set the power analyzer to trigger on the rising edge of the current, and then filled the sump pump’s water-collection hole with water. When I reached about 20 gallons, the pump turned on. As can be seen in Figure 2, the first cycle pulled 41 A, but within about 10 cycles, the current was steady at just under 20 A. These numbers seemed low enough that I should have no trouble providing power to the pump from the UPS.

Measuring Steady-State Power

Next, I wanted to see how much power the pump consumed. Once again, a power analyzer is an ideal tool to very accurately measure ac power. In Figure 3, the blue box on the right side of the IntegraVision Power Analyzer’s screen lists out the key ac power parameters. In the center of the box, you can see 492.31 W, 922.17 VA, and a power factor of 0.5339. With my UPS rated at 1200 W and 2000 VA, my pump is clearly in the UPS’s operating range.

Determining UPS Runtime

I could have determined runtime by operating the pump continuously and using a stopwatch to measure the runtime. However, I had the power analyzer, so I could make this measurement directly.

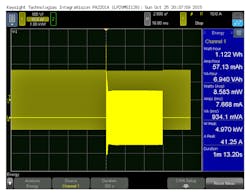

In Figure 4, you can see two waveforms. The lower-intensity waveform, which looks like a thick solid line, is the ac voltage. Notice the sweep speed is set to 2 seconds per division. That means each division is capturing 120 cycles of the ac sinusoidal voltage. With so many cycles per division, it ends up being drawn like a solid line.

If I had zoomed in the time-base, the ac cycles would have been individually shown, as in Figure 2. However, I needed the time-base wide enough to see a complete cycle of the pump.

The brighter yellow trace on Figure 4 is the current. Notice, it’s at zero until the pump comes on at center screen. Then, the current flows for approximately 6 seconds (three divisions), after which the water in the collection hole was emptied and the pump shut off.

Another type of measurement made by the IntegraVision Power Analyzer is integrated energy. In Figure 4, in the blue box on the right, you can see Amp-Hours. Amp-Hours represents the area under the curve of current versus time. When the current is zero (not flowing), no Amp-Hours are accumulated. But when the pump is on, the Amp-Hours of current flow do accumulate, and are shown as 57.13 mAh. This represents how many coulombs are pulled from the battery each time the pump runs.

To calculate the runtime, I simply divide the Amp-Hours per pump cycle into the total capacity of the battery. This UPS uses two 12-V, 9-Ah batteries connected in series. If each pump cycle takes 57 mAh, then I should be able to run my pump (9000 mAh / 57 mAH) = 157 pump cycles. Even assuming 75% efficiency in power conversion, this is still 117 pump cycles.

Conclusion

By using a power analyzer that can make single-shot measurements like a scope, I was able to measure the actual power consumption during a single pump cycle. The instrument was able to accurately tell me the energy consumed by a single cycle. By dividing the energy of a single cycle into the total energy stored in the batteries, I was able to calculate the runtime of the UPS. And now, I rest assured that in the event of a rainy power failure, my sump pump will be able to keep my basement dry long enough for me to pull out and fire up my gasoline generator.