This article is part of the This Week in PowerBites Library Series.

Up-Close and Personal at APEC 2023: A Sampler of Powerful Innovations We Discovered in Orlando

The IEEE's Applied Power Electronics Conference (APEC) is a must-go event for designers who need to keep up with the latest power-related technologies, products, and design practices. So, it's no wonder that Lee Goldberg, Electronic Design’s Contributing Power Management Editor, packed his best Hawaiian shirts and headed down to Orlando to cover this year's proceedings.

As always, the show floor was packed with all "the usual suspects,” and a few new players as well, all hawking their latest and greatest innovations. While Lee wasn't able to report on all of the exciting developments he saw, these interviews with Texas Instruments, Power Integrations, and onsemi will give you a good feel for the state of the power sector in early 2023.

Still hungry for more? You can find more videos, reports, and stories about APEC 2023 by clicking here.

High-Accuracy BMS Controller Enhances Performance, Lifetime, and Safety of Li-Ion, LiPo Batteries

Suitable for battery packs up to 25 V, STMicroelectronics’ L9961 battery-management system (BMS) provides monitoring, balancing, and protection of high-density lithium-ion and lithium-polymer batteries for a diverse range of applications. Cordless power tools, backup energy-storage systems, uninterruptible power supplies, portable and semi-portable equipment, and medical devices are among the myriad applications.

The controller's many built-in features include a dual pre-driver for controlling battery-pack safety relays, which can be programmed for high- and low-side connection. An embedded non-volatile memory for configuration data relieves the microcontroller from reprogramming the device at each startup. And an I2C interface handles configuration and host communication to share battery state of charge (SOC) and state of health (SOH).

Thanks to a high-resolution analog-to-digital converter (ADC) and current-sense amplifier, the L9961 senses cell voltages with an accuracy of ±15 mV and battery current to within 0.25%. The accurate measurements enable high-accuracy passive cell balancing and coulomb counting, and they support safety features including overvoltage and undervoltage detection, balance undervoltage protection, overcurrent detection, and short-circuit in-discharge protection.

When an external thermistor is connected, the L9961 performs pack temperature monitoring with overtemperature and undertemperature detection and pack-fuse management. The L9961 also is highly robust to support hot plugging.

While extending the battery lifetime and increasing safety, the L9961 consumes minimal energy from the battery pack. Two power-saving modes cut the current consumption down to 2 μA in deep-sleep and 5 μA in standby with the integrated voltage regulator active to resume operation quickly.

The L9961 is in production and available now in a 32-lead, 5- × 5- × 1-mm VFQFPN package. Pricing starts from $1.19 for orders of 1,000 pieces.

Standalone Active EMI Filter ICs Enable High-Density Power-Supply Designs

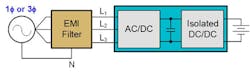

According to Texas Instruments, it’s introduced the industry’s first standalone active electromagnetic-interference (EMI) filter ICs. They’re designed to assist engineers with implementing smaller, lighter EMI filters that enhance system functionality at reduced system cost while simultaneously meeting EMI regulatory standards.

The filters help detect, process, and lower EMI in a broad range of ac/dc power supplies, on-board chargers, servers, UPS, and other similar systems where common-mode noise dominates. (NOTE: You can see TI's innovative active filter in action in our recent video "APEC 2023 Insights with Lee Goldberg".)

The new standalone active EMI filter ICs can sense and cancel common-mode EMI by as much as 30 dB at frequencies between 100 kHz and 3 MHz in single- and three-phase ac power systems. This capability enables designers to reduce the size of chokes by 50%, compared to purely passive filter solutions, as well as meet stringent EMI requirements, including CISPR 11, CISPR 32, and CISPR 25.

Capacitive Amplification Shrinks Passives

The new filter architecture uses a technique known as "capacitive amplification", developed by TI's Kilby Labs, that enables engineers to shrink the inductance value of common-mode chokes by as much as 80%, helping to cost-effectively achieve improved mechanical reliability and increased power density. The new active EMI filter ICs incorporate sensing, filtering, gain and injection stages. Offered in a SOT-23 14-pin package, the IC integrates compensation and protection circuitry to further reduce the implementation complexity and minimize the number of external components.

The new family of active EMI filter ICs includes the TPSF12C1 and TPSF12C3 for single- and three-phase commercial applications. It also features the TPSF12C1-Q1 and TPSF12C3-Q1, created specifically for automotive applications.

In addition, EMI filters meet IEC 61000-4-5 surge immunity requirements, thus minimizing the need for external protection components, such as transient-voltage-suppression (TVS) diodes. With supporting tools like PSpice for TI simulation models and quick-start calculators, designers can easily select and implement the optimal components for their system. To learn more about designing with this new family of active EMI filter ICs, read the technical article, “How a stand-alone active EMI filter IC shrinks common-mode filter size.”

Pre-production quantities of the automotive-grade TPSF12C1-Q1 and TPSF12C3-Q1 are available now, only on TI.com, in a 4.2- × 2-mm SOT-23 14-pin package. The catalog-grade TPSF12C1 and TPSF12C3 will be available on the site in pre-production quantities by end of March 2023. Pricing starts at US$0.78 in 1,000-unit quantities. The TPSF12C1QEVM and TPSF12C3QEVM evaluation modules are available for US$75.

48-VIN Charge-Pump, Step-Down, DC-DC Converter Module Claims Industry’s Highest Power Density

Murata recently released the MYC0409, a 48-VIN divide-by-4, charge-pump capacitor divider module that has all passive necessary components integrated into its low-profile PSiP package. Capable of delivering up to 72 W of power with peak efficiency of around 97%, the interleaved, switching-capacitor architecture is based on the company’s unique lossless charge-pump technology, providing extremely low input and output ripple performance.

The MYC0409 is designed to operate in a fixed divide-by-4 mode over an input voltage range of 20 to 60 V, which extends its usage to 24- to 36-V input applications typically employed in consumer battery charging and industrial supplies. The charge-pump-based dc-dc converter supports an output voltage range of 5 to 15 V with load currents of 6 A and up to 72W delivered to the external load. Featuring an extended temperature range of −40 to +105℃, the MYC0409 is fully protected with input undervoltage and overcurrent protection plus thermal shutdown fault detection.

Low-Profile Form Factor

The solution occupies a compact footprint with 2.0-mm height, suiting it for low-profile applications and placement on the underside of system boards. MYC0409 devices can be connected in parallel to provide high-power, high-efficiency solutions for a variety of 48- to 12-V step-down conversion applications such as data centers, networking routers, base stations, and optical equipment.

This compact, low-profile form factor gives system designers the flexibility to choose between creating a single high-power, bulk 48-V bus system with several MYC0409 devices connected in parallel or further reducing system PCB copper losses by distributing individual MYC0409 devices closer to the point-of-load.

The 11.5- × 9.5- × 2.0-mm MYC0409 comes in land-grid-array (LGA) packaging. Contact regional sales representatives for information about evaluation kits, samples, and parts. To learn more, visit the product page or watch the webinars “How Murata is Changing the Power Density Paradigm – Part 1” or “How Murata is Changing the Power Density Paradigm – Part 2.”

DC-Link Capacitors Stabilize Power Converters in Charging and Photovoltaic Systems

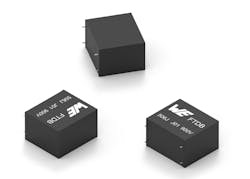

Würth Elektronik introduced a new series of film capacitors specially designed for dc-link applications. The WCAP-FTDB series components, which can be used apps ranging from 500 to 1200 V, are characterized by high ripple-current capability. This makes them particularly attractive for use in ac-dc and dc-dc converters for charging systems and power electronics in e-mobility or in renewable-energy solutions. The 24-model product family offers capacitance values from 1 to 75 µF.

The capacitors possess robust characteristics that are essential for stabilizing dc-link voltages. Their metallized polypropylene film construction gives them self-healing properties that cause short circuits to “burn out” in a manner that restores the dielectric. The WCAP-FTDB series also is significantly more durable than other capacitor types, according to Würth, suiting them for wind turbines, solar farms, and other applications with long maintenance cycles.

The capacitor series is housed in a boxed THT package with pitch of 27.5, 37.5, or 52.5 mm. The devices’ operating temperature range extends from −40 to 105°C, with their respective maximum voltage ratings maintained at up to 85°C. Würth Elektronik provides free samples and offers a wide range of characteristic measurement data of the capacitors in the REDEXPERT online tool.

U-MOS MOSFET with Fast Reverse Recovery Boosts Synchronous-Rectification Efficiency

The TPH9R00CQ5, a new 150-V N-channel power MOSFET launched by Toshiba Electronics, is specifically designed for use in high-performance switching power supplies like those used in communication base stations as well as other industrial applications. Based on the company’s latest-generation U-MOS X-H Trench process, the new MOSFET has a maximum VDSS rating of 150 V and current handling (ID) of 64 A. It also features a very low drain-source on-resistance (RDS(ON)) of 9.0 mΩ (max), an improvement of more than 40% over Toshiba's previous-generationTPH1500CNH1.

In high-performance power solutions that use synchronous rectification, reverse recovery performance is particularly important. Due to inclusion of a high-speed body diode, the new TPH9R00CQ5 reduces the reverse-recovery charge (QRR) by around 74% (to 34 nC typ.), compared to previous devices. In addition, the reverse-recovery time (tRR) of just 40 ns is an improvement of over 40% compared with earlier devices.

Along with a low gate charge (Qg) of 44 nC, these improvements contribute significantly to reduced losses and increased power density in high-performance, efficient power solutions. The new device also lowers spike voltages created during switching, thereby improving EMI characteristics of designs and reducing the need for filtering. It comes in a versatile, surface-mount SOP Advance(N) package measuring just 4.9 × 6.1 × 1.0 mm.

To support designers, Toshiba developed a G0 SPICE model for rapid verification of the circuit function as well as highly accurate G2 SPICE models for accurate reproduction of transient characteristics.

Advanced reference designs are now available from Toshiba’s website. These include a 1-kW non-isolated buck-boost dc-dc converter, a three-phase multilevel MOSFET-based inverter, and a 1-kW full bridge dc-dc converter.

Smart, Accurate, and Rugged Digital DC Current Sensors Simplify High-Power Measurements

Riedon Inc., a specialist power and precision resistor manufacturer, rolled out its new SSD Smart Shunt series of digital dc current sensors. Their accuracy, energy efficiency, and robust design make them well-suited for a wide variety of battery-related current-sensing applications. These include large-scale energy-storage banks, renewable-energy generation infrastructure, industrial motor drives, building automation systems, and EV charging stations.

Like Riedon's original Smart Shunt devices (introduced in mid-2020), the new series combines the high-amperage capabilities of conventional passive shunt resistors and the accuracy of closed-loop Hall-effect current sensors. The family integrates the original sensing circuitry with a 16-bit automotive-grade microcontroller, 24-bit ADC (with buffered analog Inputs), flash-memory storage, and communications interface (RS-485/Modbus RTU or customizable CAN bus).

Housed in a digital system-in-package (SiP) , these highly integrated smart sensors bring plug-and-play simplicity to current measurements, battery voltage monitoring, and coulomb counting. As a result, they offer a unique combination of accuracy, stability, and electrical isolation, while also eliminating the need for periodic calibration.

The SSD Digital Smart Shunt devices have current-sensing capabilities rated from 100 A (2 kA peak) to 1 kA (20 kA peak). They exhibit better than ±0.1% full-scale accuracy, and their full-scale linearity remains within a ±0.1% margin. The devices also feature excellent long-term stability with less than ±0.1% deviation during 1,000 hours of operation (at 60°C terminal temperature).

A −40 to +115°C (ambient) operational temperature range enables these devices to be used in harsher environments than other current-sensing products. The built-in flash memory has error correction code (ECC) and autocorrect on single-bit errors.

These sensors come in packages with footprints of just 68.8 × 80 mm and have extremely low profiles (going down to 16.4 mm). They’re far smaller than equivalent current transducers on the market for the rated voltages offered, according to Riedon.

More about these current sensors can be found at www.shunts.com.

PCIM to Present Online Tutorials on Soft Switching, Advanced Magnetic Design, and More

PCIM 2023, Europe's premier power technology conference, will take place from May 7-8 in Nuremburg, Germany, with live streaming access available to remote attendees. In addition to a lively exhibition floor, PCIM will host two days of intensive seminars and tutorials on the latest technologies and design practices. A full listing of these classes can be found here. The following is a sampler of the program to whet your interest:

A seminar entitled “Magnetic Design for Very High Efficiency and Power Density” will be held on May 8, from 8 am to 5 pm (GMT +2). The seminar will address the latest trends in magnetic technologies being used to overcome the challenges the industry is facing in the design of very high-density and high-efficiency power converters. It includes a comprehensive analysis of leakage inductance, parasitic capacitances, and common-mode EMI.

The seminar is highlighted with many design examples ranging from very high-efficiency ac-dc adapters to multiple-kilowatt dc-dc converters reaching 99% in efficiency. The material presented in the seminar will be especially useful for engineers in automotive, industrial power, and low- and medium-power applications such as ac adapters.

The tutorial entitled “New Soft Switching and Magnetic Technologies for Very High Efficiency and Power Density” is also scheduled for May 8, from 8 am to 5 pm (GMT +2). The focal point will be a novel soft-switching technology applied to conventional square waveform topologies such as flyback, two-transistor forward, half-bridge and full-bridge. These new technologies can convert the classical hard-switching topologies into soft-switching topologies through minor hardware change and, in some cases, simply applying new control techniques.

Additional information about the conference and its program can be accessed here, while registration for live and online attendance is available here.

Read more articles in the This Week in PowerBites Library Series.