Functional Safety Confers Competitive Advantage in Automotive, Industrial Apps

Members can download this article in PDF format.

From the highway to the factory floor, automation is driving the need for functional safety. Automotive airbag and braking systems have long incorporated functional safety. However, now the trend toward increasing vehicle electrification is extending the need for functional safety to autonomous driving and advanced driver-assistance system (ADAS) functions, battery-management systems, and systems employing sensor fusion. In addition, everything from industrial robotic systems to home appliances can benefit from functional-safety features.

Frequently, automotive and industrial products require certification in accordance with the IEC 61508 industrial and ISO 26262 automotive standards and their respective safety integrity level (SIL) and automotive SIL (ASIL) values. But even if your product doesn’t require certification, building in functional safety can give you a competitive advantage.

Sponsored Resources:

- Find resources to streamline your functional safey design

- Streamlining Functional Safety Certification in Automotive and Industrial

- Understanding Functional Safety FIT Base Failure Rate Estimates per IEC 623801

Functional-Safety Categories

An effective functional-safety design begins with choosing the right parts and making sure your supplier can provide the necessary support. Texas Instruments has streamlined the process, offering products in three functional-safety categories along with access to engineering expertise and functional-safety-related documentation covering topics such as failure-mode distribution (FMD); failure modes, effects, and diagnostic analysis (FMEDA); and fault-tree analysis.

The first of TI’s three functional-safety categories, the Functional Safety-Compliant category, includes MCUs, processors, and analog motor drivers that may have integrated safety features. TI developed these products using a functional-safety development flow certified by agencies such as TÜV SÜD. Specific products in this category include Hercules MCUs, the TPS65381A-Q1 multi-rail power-management IC (PMIC), and the C2000 real-time controllers.

The Functional Safety Quality-Managed category includes devices specifically designed for systems requiring functional safety, yet they’re fabricated using the TI-wide standard quality-managed development flow instead of a certified functional-safety development flow. Among the specific products in this category are the TCAN4550-Q1 automotive system-basis chip (SBC) with integrated CAN FD controller and transceiver as well as the LP87702-Q1 dual buck converter and 5-V boost converter/bypass switch with integrated diagnostic functions required in ASIL-compliant mmWave radar systems.

The Functional Safety-Capable category presents less-complex ICs that generally lack the internal monitoring and diagnostics features found in devices in the other two categories. Nevertheless, they come with key information such as failure-in-time (FIT) rates and FMD that engineers can use in their own safety analyses. Specific products include the TMP61-Q1 linear thermistor featuring < 1% long-term sensor drift; the TPS3840-Q1 voltage supervisor IC; and the TPS7A16A-Q1 AEC-Q100-qualified, 60-V, 5-μA quiescent-current, 100-mA low-dropout voltage regulator.

Development Process

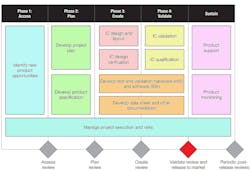

To deal with the complexities of functional-safety development, you may need information about a company’s safety culture and process beyond factors such as TÜV SÜD certification status. To help fill any information gaps, TI created a standard quality-managed development process (see figure), which it overlays with several functional-safety-specific activities (see table).

The process decreases the probability of systematic failures and breaks development into four phases:

- The Assess phase involves identifying new-product opportunities and determining whether functional-safety process execution is required.

- The Plan phase defines component-level SIL or ASIL capabilities and results in a product specification.

- The Create phase involves IC design, layout, and design verification as well as development of component-level functional-safety requirements.

- The Validate phase embodies IC validation and qualification and extends through the release of functional-safety documentation. You can use the documentation to help you comply with a range of automotive and industrial standards, including ISO 26262-4 or IEC 61508-2.

These four phases are followed by a Sustain period that involves product support and monitoring along with the documentation of issues through a product’s end-of-life.

Random Faults and BFR

In addition to systematic failures, products are subject to the occurrence of inevitable random faults, often quantified by the base failure rate (BFR), which in turn is affected by factors such as temperature, voltage, and number of operating hours. BFR relates to other metrics, such as safe failure fraction (SFF), probability of failure per hour (PFH), single-point fault metric (SPFM), latent fault metric (LFM), and probabilistic metric for random hardware failure (PMHF). In addition, FIT is an estimate of the number of failures that could occur in a billion cumulative hours of a product’s operation. ISO 26262 and IEC 61508 specify acceptable values of random hardware failure metrics for each ASIL and SIL value, respectively.

Several methods exist for generating estimates that can be used in functional-safety analysis, including those outlined in the Siemens SN 29500 standard for the reliability prediction of electronic and electromechanical components. SN 29500 includes lookup tables to find reference FIT rates and reference temperatures for component types including ICs, discrete semiconductors, passive components, switches, relays, lamps, and connectors.

The standard describes the calculations necessary to translate from a reference FIT rate to an adjusted FIT rate for the actual expected operating conditions. System integrators can refer to the SN 29500 standard to derive their application’s specific FIT rate for a TI-supplied component.

Conclusion

Functional-safety considerations are increasingly important as automation pervades automotive and industrial applications. A careful functional-safety design can speed certification to standards such as IEC 61508 and ISO 26262. Even if your product doesn’t require formal certification, functional safety can confer a competitive advantage. TI employs a quality-managed development flow overlaid with functional-safety activities to produce the ICs you need for the success of your functional-safety project.

Sponsored Resources:

About the Author

Rick Nelson

Contributing Editor

Rick is currently Contributing Technical Editor. He was Executive Editor for EE in 2011-2018. Previously he served on several publications, including EDN and Vision Systems Design, and has received awards for signed editorials from the American Society of Business Publication Editors. He began as a design engineer at General Electric and Litton Industries and earned a BSEE degree from Penn State.