I bought a 90-W equivalent LED floodlight at Home Depot several years ago. It’s obsolete now, but was state-of-the-art when I purchased it. My first abuse was to drop it, which cracked the glass lens. It’s a PAR38-style waterproof exterior light, but I use it to light my desk area inside. The crack was no problem for the last few years. A few months ago, one of the LEDs inside the lamp seemed to turn blue. It was time for a teardown (Fig. 1).

1. The Cree PAR38 floodlight from 2013 is a rock-solid design with a heavy metal fluted base, a metal-clad PCB for the LEDs, and a high-frequency power supply.

I broke off the cracked glass lens and applied power to the lamp. It became obvious that one of the LEDs was indeed glowing blue, and another one had intermittent contact (Fig. 2). After removing the reflector, the LED printed circuit board (PCB) had one location that looks like it never had an LED at reference designator G16 (Fig. 3). Cree may have done this since the LEDs were efficient enough whereby they did not need to fully populate the PCB to get the required brightness. The PCB has a metal substrate, and its 2013 copyright date belies the lamp is about four years old.

2. Since I had already cracked the lens, I broke it out completely to reveal one LED was shining blue since its phosphor-coated lens had broken off.

3. The guts of the lamp are remarkably well-made. The PCB slides over the metal boss and makes contact with two spring metal contacts. The PCB is metal-clad to get the heat out and down to the fluted base. The missing LED at G16 seems to never have been loaded.

Creative Cree

Cree is a great company. Based in North Carolina, they make SiC (silicon carbide) RF chips, which then got them into GaN (gallium nitride) direct-bandgap power RF chips, and subsequently positioned them to make direct-bandgap InGaN (indium gallium nitride) LEDs on a SiC substrate. The direct bandgap makes the LEDs efficient producers of light in the converse way direct-bandgap GaAs (gallium arsenide) solar cells are more efficient receptors of light than silicon solar cells. Cree’s process expertise for these wide-bandgap semiconductors serves them in both the RF and consumer LED markets.

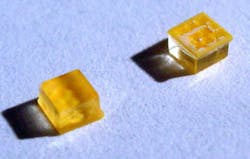

The blue LED was one that had its lens knocked off, probably loosened when I dropped the lamp years ago. As I tugged on the PCB trying to take it apart, several other lenses fell off (Fig. 4). The lenses must hold the phosphors that change the blue light to white. The fluted base is metal, probably zinc, to conduct heat out of the LED PCB.

4. As I tugged on the PCB, a few more lenses popped off the LEDs. The yellow color may come from fading or it may be to balance the color to give the rated 3000K color temperature.

The Edison screw base connects to the fluted metal base with three plastic snaps (Fig. 5). The Edison screw base has the power supply potted into it. That circuit board extends to engage an intermediate contact assembly containing spring terminals that press against the LED PCB. The spring contacts allow for the thermal expansion of the LED PCB.

5. The base snaps together. The contact assembly snaps into the protruding boss, and the Edison screw base snaps into the fluted metal heat sink.

Enlightening Design

One side of the power-supply PCB has a capacitor visible (Fig. 6). Before I took these pieces apart, I measured the voltage on the LEDs at 235 V dc, with only 2.1 V ac ripple, which is pretty remarkable. With the LED PCB removed, the power supply shot up to 315 V. Then it would crowbar and output would decline to 259 V, at which point the supply would once again shoot up to 315 V. This took about eight seconds.

6. The power-supply PCB has a large capacitor on the same side as the output contacts.

I was impressed with the robust design under no-load conditions. I am confident it would also survive an output short circuit, but I want to play with this HV power supply a bit more before I risk breaking it.

The other side of the power-supply PCB holds the main switching inductor (Fig. 7). Its size is commensurate with the 18-W power consumption of the device. Unloaded, it seemed to be switching at 400 kHz; while loaded, it sped up to 500 kHz. The potting was quite soft. This is a tradeoff when potting power electronics. Hard potting can conduct heat out of the circuit, but it will break the leads and components under thermal expansion. This high-frequency switching supply must be efficient enough to get away with soft potting. I don’t believe there is any need to damp acoustic noise, since this switching frequency is far beyond the range of hearing.

7. The other side of the power-supply PCB has the switching inductor. The supply seems to operate at 500 kHz. The base is plastic, so electromagnetic interference (EMI) must not have been a problem for the Cree engineers.

How Does a New Model Match Up?

I was so impressed by this old Cree lamp, I replaced it with a new one. This time I got a spotlight with a 25° pattern (Fig. 8). This reduces glare on my monitors while giving even better lighting to my keyboard and reading area. The new lamp is also a PAR38 waterproof style, with a 120-W equivalent output. Its lens is plastic, and it seems to be a great job of cost reduction. It’s rated at 1200 lumens with 19-W input power, for an efficiency of 63 l/W. Color temperature is 3000K. Contrast this to the older 1500-lumen design with its 18 W-input and efficiency of 83 l/W.

8. The teardown bulb is on the left. I replaced it with the latest Cree design. It’s got nearly the same performance at half the price. It also is entirely plastic, a testament to the efficiency of the power supply.

9. The glass lens on the teardown lamp cracked when I dropped it years ago. The lens on the new lamp is plastic, most likely shatterproof polycarbonate. The LEDs are on a plane, perhaps because the new lamp is a 25° spot as opposed to the 47° flood of the old lamp.

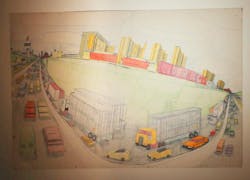

The new Cree bulb has the LEDs arranged in a plane, unlike the old one (Fig. 9). The new bulb is not quite as efficient and bright, but based on extensive field testing, I like it much more than the 47° bulb in the teardown (Figs. 10 and 11). The amazing thing is the new bulb is 10 dollars versus the 21 dollars for the older design. The new bulb also has a better color rendering index (CRI), 90, versus 80 for the old bulb. Best yet, the new bulb’s plastic lens won’t shatter when I drop it, unlike what happened with the old bulb.

10. My Wesley Willis ink drawing is dim when illuminated by the teardown lamp.

11. The 25° spot of the new lamp illuminates the Wesley Willis artwork much better. The new lamp also has a better color rendering index.

All in all, I am delighted with both Cree products, unlike the Philips PAR38 bulb I bought years ago that turns itself off when I use my paper shredder. Perhaps the Philips engineers should have called my pals at the Linear Technology part of Analog Devices. The LT apps folks would have ensured there was no conducted EMI (electromagnetic interference) before the product shipped.

About the Author

Paul Rako

Creative Director

Paul Rako is a creative director for Rako Studios. After attending GMI (now Kettering University) and the University of Michigan, he worked as an auto engineer in Detroit. He moved to Silicon Valley to start an engineering consulting company. After his share of startups and contract work, he became an apps engineer at National Semiconductor and a marketing maven at Analog Devices and Atmel. He also had a five-year stint at EDN magazine on the analog beat. His interests include politics, philosophy, motorcycles, and making music and videos. He has six Harley Sportsters, a studio full of musical instruments, a complete laboratory, and a video set at Tranquility Base, his home office in Sun City Center Florida.