Thermal Management: New Solutions for New Challenges

This article is part of the TechXchange: Cool Designs.

As systems like servers, switches, and routers deliver higher speeds and grow more sophisticated, their power requirements rise substantially, too. Higher power means higher operating temperatures, resulting in the need for new solutions that can handle more heat. Traditional thermal-management solutions rely on gap pads or thermal pads to dissipate heat from critical component areas, but these may not be robust enough to handle the higher heat generated by next-generation data-center equipment.

In this article, we’ll examine the challenges of thermal management in data-center equipment and look at advances in thermal-management technology that overcome those issues.

Thermal-Management Challenges

Upgrades in data-center architecture and systems are making things denser. We’re sometimes doubling, tripling, or even quadrupling the amount of data running through the same form factor, which of course heats up the components and the interiors of data-center systems. Heat wears components out more quickly, requiring most customers to cool their systems more effectively. As the insides of systems become more crowded, there’s limited space for heat to dissipate.

Traditional Solutions

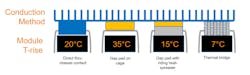

Typically, the industry has used three types of heat-management solutions for cooling components. One option is to use direct metal contact with a heat sink. The designer uses a metal slug between the device and the heat sink. This method provides some cooling, but it usually relies on forced air flow, which is increasingly problematic because there’s more heat generated and less space between the device and the heat sink in which air can flow.

Another option is thermoelastic interface materials (TIMs), or gap pads. TIM materials are spongy, rubberized materials that act as a conduit between a hot module and a cold plate. TIMs are elastic, so they can do a better job than some direct metal contacts in terms of contacting with the module and conducting heat away from it and into the heat sink.

However, one of the pain points some customers are experiencing with gap pads is that over time, the material hardens and tends to degrade in performance. In addition, TIMs may require high levels of compression to get the thermal transfer performance demanded by some customers. In effect, the TIM is squeezed against the optical module, which requires external compression hardware. This is a more complex design, and since the TIM’s elasticity degrades over time, the gap pads need to be replaced periodically.

Finally, some designers use a riding heat sink bonded to a thermal gap pad. With this approach, the designer is primarily considering ganged cages under one heat sink, and the gap pad helps with thermal transfer between individual cages and the heat sink. This solution can have the same drawbacks as a gap pad alone, requiring compression hardware and needing periodic replacement.

New Thermal Management Technology

Engineers at TE Connectivity recently developed a new solution to thermal management that leverages the strengths of gap pads while overcoming their limitations by creating a metal, mechanical version of a gap pad. Since the design uses a copper-based material, it’s resistant to compression and therefore doesn’t have to be replaced. In addition, the metal material delivers superior thermal resistance and thermal transfer values. Furthermore, it doesn’t normally rely on external compression hardware to make good contact with the optical module (Fig. 1).

This type of solution is well-suited for applications with limited or no air flow, or where customers use fixed heat-sink solutions such as gang heat sinks or liquid cooling.

Such a device can reduce the overall complexity in a line card or similar application. That’s because in the intended use cases, the thermal bridge doesn’t require additional compression hardware around the gap pad as is usually required for gap-pad compression. It’s composed of multiple plates integrated with springs to give them the ability to adjust to distances between the heat-transfer device and optical module.

Overall, the thermal performance is superior to most gap pads or metal-to-metal heat sinks because it conducts heat more efficiently. There’s one millimeter of travel built into the heat-transfer device; thus, it can make contact more closely with optical modules. In addition, it can conduct heat better because it’s a metal solution.

When compared to traditional heat-transfer solutions, the new thermal transfer technology can offer up to two times better thermal resistance, according to the company (Fig. 2).

In summary, key takeaways of the thermal-bridge heat-transfer technology include:

- A near-zero plate gap in construction for optimized compression and thermal transfer.

- Optimization for applications using cold plates with liquid cooling or heat pipes, ganged heatsinks, or direct chassis conduction applications with little to no airflow.

- Consistent, long-lasting thermal performance with an elastic compression design that can be resistant to setting and relaxation over time.

- Low and consistent compression force between the cold plate and input/output (I/O) plug.

- Better durability than most traditional thermal technologies, thereby reducing component replacements needed during servicing.

As system designers seek better ways to dissipate more heat associated with increasing system power requirements—specifically in fixed cooling applications with restricted airflow, liquid cooling, or cold plates—a different technology approach is needed. The new heat-transfer technology discussed in this article could offer that alternative.

Zachary Galbraith is Global Product Manager at TE Connectivity.

About the Author

Zachary Galbraith

Global Product Manager, TE Connectivity

Zach Galbraith is a Global Product Manager for TE Connectivity, responsible for the high-speed I/O product lines. His primary focus is driving next-generation product development efforts to continue to grow TE’s portfolio and remain an industry leader in this space. Zach has worked for TE Connectivity for 12 years, with various roles throughout the organization, including Industrial, Medical, Solar and most recently, Data and Devices. Zach has a BS in Industrial Engineering from Elizabethtown College, and an MBA from Shippensburg University.