Demand for Automotive Timing Requirements Puts Focus on Clock Generators

What you’ll learn:

- The number of precision reference clocks needed in automotive electronics is increasing complexity in system design and changing best practices.

- The benefits of changing timing requirements from quartz to silicon.

- The benefits of consolidating reference clocks into a simplified clock tree.

- How silicon-based timing devices can provide flexibility to system designers and help them meet safety requirements.

Automotive electronics are evolving faster than ever, especially as manufacturers bring feature-rich infotainment systems and advanced driver-assistance systems (ADAS) to their product lines, while simultaneously developing fully autonomous vehicles. Advanced semiconductor technologies are aiding in the rapid development and deployment of these new vehicle systems.

On that front, semiconductor manufacturers are bringing more automotive-grade products to market, including higher bandwidth processors, GPUs, high-speed PCI Express switches, Ethernet switch SoC/PHYs, and FPGAs. Adoption of the latest generation of automotive-grade IC platforms and connectivity solutions has brought significant improvements in system capabilities, features, performance, and cost, but it also presents new design-complexity challenges for system designers.

One of those challenges is fulfilling the growing need for high-precision, low-jitter reference clocks for high-speed SerDes in processors, FPGAs, switch SoCs, Ethernet PHYs, USB PHYs, and PCIe Express Gen3/4 endpoints. All of these devices are quickly finding their way into automotive networking gateway, infotainment, digital cockpit, ADAS, LiDAR, and automated driving control units.

As the functionality and sophistication of automotive electronics escalate, so does the number of precision reference clocks that are needed for these systems. Thus, system designers are borrowing proven best practices in timing design from the computing and communications markets, where silicon-based timing solutions have been the preferred solutions for decades.

Evolution Underway from Quartz to Silicon

Historically, automotive-system designs have employed lower-bandwidth processors and microcontrollers, which only required one or two single-ended reference clock frequencies for each board design. Fulfilling these timing requirements was straightforward because they simply used one or two quartz crystals or crystal oscillators.

As the number of reference clocks increases in modern automotive electronics design, the easiest way to satisfy the timing requirements is to simply add more quartz crystals or oscillators. However, scaling the number of quartz-based components has numerous drawbacks and limitations. Oftentimes, quartz crystals and oscillators are the components in automotive design that carry the highest failure-in-time (FIT) rates, so adding more of them is highly undesirable for system reliability reasons.

For many years, the communications, computing, industrial, and consumer markets have used silicon-based integrated clock-generator solutions instead of quartz crystals and oscillators to fulfill their precision reference-clock timing requirements. As processor speed and SerDes bandwidth level rise, the jitter requirements on the reference clock become more difficult to meet.

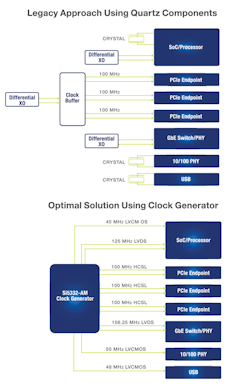

The latest generation of automotive networking gateways, ADAS sensors, and automated driving platforms are using high-bandwidth processors, FPGAs, 1G/10GbE connectivity, and PCI Express Gen3/4/5 data buses, which require differential clocks with less than 500-fs RMS phase jitter. Clock generators can consolidate the functionality of up to eight quartz crystals or oscillators into a single IC and provide excellent RMS phase jitter performance (<300 fs RMS) on clock outputs, while offering numerous additional features and benefits that help simplify system reference-clock design.Simplifying Clock Trees Reduces Points of Failure

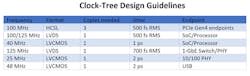

Selecting and defining an optimal timing solution can be simplified by summarizing the set of reference clocks needed in a system design. A set of reference clocks is often referred to as a “clock tree.” A clock tree usually includes the input reference frequencies, output clock frequencies needed by endpoints, the clock output format levels, and the maximum jitter performance level for each reference clock, which is typically specified by each endpoint device manufacturer (see table).

In addition to the new automotive processor, FPGA, connectivity, and data-bus semiconductor solutions being released into the market, AEC-Q100-qualified silicon-based timing solutions are available now to simplify clock-tree design complexity in automotive applications. By consolidating reference clocks into an integrated clock generator, system designers can reduce points of failure, boost system reliability, and realize significant advantages in jitter performance and frequency flexibility. Other benefits include a reduction in board space area and lower total solution cost over legacy quartz-based devices (see figure).

Addressing Hurdles: Emissions and Redundancy

Safety continues to be at the forefront of all automotive electronics designs with the introduction of ISO26262 and ASIL requirements. Designing to these new standards may also create new challenges. Silicon-based timing devices can aid in meeting system safety-level goals by offering redundant primary and backup reference input capability, health-status monitoring features, and fault-detection indicator pins that can interface with an ASIL-rated MCU or with a system safety-manager IC.

In the past, automotive electronics system designers have been reluctant to adopt clock generators because of the potential emissions that could fail CISPR25 Class 4 or Class 5 limits by routing single-ended LVCMOS clocks over long traces. Spread spectrum has been a common feature to reduce emissions, but a limited number of frequencies and endpoints can tolerate a reference clock with spread spectrum applied.

System designers can now overcome these design challenges by using complementary LVCMOS output drivers, available in the latest generation of AEC-Q100-qualified clock generators. When combined with modern layout design guidelines, emissions levels have been shown to stay within CISPR25 limits.

As automotive electronics continue to evolve and grow in complexity, semiconductor suppliers are offering a greater array of new AEC-Q100 devices that have only been available in industrial-temperature-grade options. The newest generation of AEC-Q100-qualified clock generators maximize flexibility and programmability, allowing system designers to fully customize a solution to a specific set of clock-tree requirements in a matter of minutes, instead of waiting for a customized device to be developed. If changes are needed during product development, they can be easily made through user-friendly software or directly in-system using an I2C port.

Conclusion

With a focus on improving passenger safety and experience, automobile manufacturers are quickly adopting new networking, ADAS, and automated driving systems that leverage advanced semiconductor processors, FPGAs, GPUs, and Ethernet switches/PHYs. Adopting these new, higher-bandwidth platforms increases design complexity, escalating the need for high-precision, low-jitter, single-ended and differential reference clocks.

The introduction of automotive-grade, AEC-Q100 clock generators provides designers with integrated, high-performance solutions capable of consolidating entire clock trees into a single IC while improving reliability and reducing system cost over legacy quartz-based crystal and oscillator solutions.

About the Author

Kyle Beckmeyer

Senior Marketing Manager, Silicon Labs

Kyle Beckmeyer serves as a senior marketing manager for Silicon Labs’ timing products. Kyle is responsible for managing product strategy, new production introductions, and business development in data-center and automotive markets. Kyle has over 15 years of timing product experience. He holds a Bachelor of Science in electrical engineering from the University of California, Davis and a master’s degree in business adminstration from Santa Clara University.