More Electrification Means Greater Automobile Efficiency (.PDF Download)

Automotive designers have been replacing mechanical components with electric alternatives almost since the first horseless carriage caused consternation in horse-drawn traffic and pedestrians alike. The earliest vehicles, for example, used kerosene lamps for lighting, but they didn’t last long—the first electric light for vehicles came out in 1906. More recent innovations have included high-intensity lighting (HID), LED lamps, and auto-leveling headlights. A similar pattern is found across the vehicle: The steady replacement of mechanical functions by their electronic equivalents.

Several factors are driving the switch from mechanical to electronic technology. Electronic solutions tend to increase the complexity and perhaps cost of the design, but they offer higher performance, higher efficiency, smaller size, and lower weight. They also allow designers to include features that aren’t feasible, or even possible, with mechanical designs.

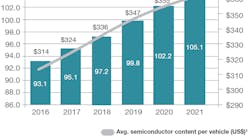

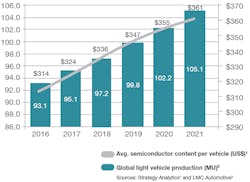

As a result, the number of electronic modules has shown a slow-but-steady increase over several decades. The per-vehicle semiconductor content by value has also risen, despite the plummeting cost of individual components. As shown in Figure 1, this trend is expected to continue.

1. The per-vehicle semiconductor content is forecast to continue its steady ramp-up.

Let’s take a look at two areas—body electronics and powertrain—and see how each have benefited from increased electrification, some of the changes we can expect to see over the next few years, and how TI products help pave the way.