October 2020 Tech Focus: Test Sockets Get a Plug

Playing a crucial interconnect role in integrated circuits and semiconductor testing, test sockets, aka package probes, serve the role of connecting a device and its tester. IC sockets are categorized into two 1) test sockets for measuring electrical characteristics, or 2) burn-in sockets for testing reliability. IC sockets’ applications include failure analysis engineering test, production test, burn-in, and others. Most IC sockets are compression-mounted, and can be designed to fit an existing PC-board footprint.

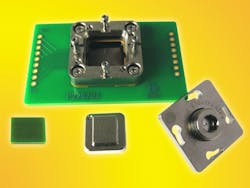

Ironwood Electronics recently designed a new 0.25 pitch socket using a high-performance elastomer capable of 75 GHz, very low inductance and wide temperature applications. The 1280 WLCSP socket is designed for 10 x 8 mm package size and operates at bandwidths up to 75 GHz with less than 1dB of insertion loss and a contact resistance of ~20 milliohms per pin. The socket is mounted on the target PCB with no soldering, and has a small footprint. This socket uses a bolt-on lid with an integrated compression mechanism, you simply adjust the compression screw to the required torque. This socket can be used for hand test and temperature cycling as well as debugging application in development and device characterization. The 1280 WLCSP socket is constructed with high performance and low inductance elastomer contactor. The temperature range is -55 C to +160 C. Ironwood Electronics can design similar sockets for your fine pitch applications Pricing for the 1280 WLCSP socket is $3800 at qty 2; with reduced pricing available depending on quantity required. Ironwood Electronics

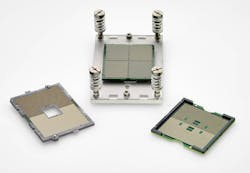

Extra large array socket series

LEMO connector is known for its Push-Pull connector, and their new harpoon earthing pins enable pre-installing easily variable receptacles and sockets. The advantage of these press-fit contacts is faster pre-assembly, with no need to place washers and screw multiple times. Simply align the connector and push firmly. This pre-assembly will enable the assembly house or final customer to turn the PCB board upside down and run the parts through the reflow soldering oven. This solution is planned for elbow and straight PCB sockets of 0B & 1B series. The current design works specifically with 1.6mm thickness boards. LEMO