Q&A: A Closer Look at Microsemi’s Rad-Tolerant FPGAs

This file type includes high resolution graphics and schematics when applicable.

Radiation in space can destroy electronics like FPGAs. Thus, designing for space can be a challenge with cumbersome and complex mitigation techniques and strategies. I spoke with Ken O’Neill, Director of Marketing for Space and Aviation at Microsemi Corp., about the key features of RTG4, its latest radiation-tolerant FPGA family.

Wong: From your experience in space FPGAs, what made you develop the RTG4?

O’Neill: The need for high-speed, on-board signal processing in satellites is increasing as demand for information (images, science data, etc.) grows. However, downlink bandwidth is not increasing at the same pace as the demand for information. As a consequence, satellites must perform more processing in space, so that the limited downlink bandwidth is used for processed information rather than raw data.

This requires high-density, high-performance payload processing electronics. With the RTG4 FPGAs, we enable designers to achieve high rates of signal processing without sacrificing radiation hardness. Our FPGAs are more flexible than radiation-hardened ASICs, have more signal-processing features than any other radiation-tolerant FPGA, and have complete immunity to configuration upsets.

Wong: Microsemi has been involved in space development for a long time now. Can you outline your space heritage?

O’Neill: Microsemi’s heritage in space started with the Atlas launch vehicles in 1957. The first space flight using Microsemi FPGAs was in 1991 using an 883B military part. Then in 1992, we sold our first parts with production screening specifically intended to meet the needs of space customers. This was to support the GOES-2000, SILEX, and Cassini missions.

The first parts with deliberate radiation hardening (in this case, hardening by process) were available in 1996. The current generation of RT FPGAs (hardening by design) started with the introduction of the RTSX-SU FGPAs in 2004. Since then, we have been on multiple space projects with our RT FGPAs, such as in 2005 with the Mars Reconnaissance Orbiter using an RTSX-SU as well as the in 2011 with the Curiosity Rover using RTAX and RTSX-SU FPGAs. We are really grateful that customers trust us with their space designs, and that is reflected in our numbers. We currently account for over 80% of the space FPGA market.

Wong: Where are RTG4s needed in a spacecraft?

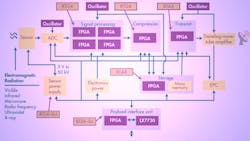

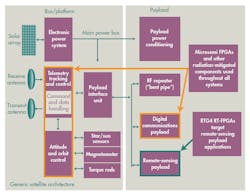

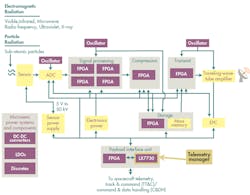

O’Neill: RTG4 brings risk-mitigation, ease-of-use, and reliability advantages, and provides a compelling alternative to ASICs (which have expensive non-recurring engineering—NRE—charges and introduce cost and schedule risk) and SRAM FPGAs (which have radiation configuration-upset issues). This makes it very useful in many space applications, including remote-sensing payloads (Fig. 1). Satellites used for weather forecasting, climate research, astronomy, astrophysics, and imaging all have remote-sensing payloads.

RTG4 offers advantages for the data-crunching parts of the system—the signal-processing engine and the compression engine (Fig. 2). The other blocks are usually on separate circuit cards and cannot be integrated into the RTG4 design. Our existing FPGAs—RTAX, RTSX-SU—will continue to play valuable roles in command and control, interfacing, and low-to-mid-rate signal processing in those applications.

Even though the example here is remote sensing, there are several initiatives to build extensive, low-cost constellations of communication satellites to bring Internet service to the earth. RTG4 is a candidate for those missions as well.

Wong: What kind of radiation effects can we expect to see in space? How do these affect digital systems?

O’Neill: In space, there are two main radiation factors for digital designs to consider: the total ionizing dose (TID) effects that degrade a parts performance and functionality due to the accumulation of radiation; and the single-event effects (SEEs) that are instantaneous upsets, transients, or permanent damage due to particle radiation.

TID is the cumulative effect of radiation. This occurs when gamma rays, X-rays, and protons create electron-hole pairs in the silicon oxide. If the device is powered on, the electrons and holes will accumulate at the electrodes. This can change the voltage threshold and leakage current. It will degrade the device’s performance and cause high standby currents and eventually loss of functionality. Typically, TID requirements for missions in low Earth orbit are 10-20 kRAD while geosynchronous missions require 100 kRAD. With the RTG4, Microsemi has developed an indirectly coupled interconnection scheme for flash interconnect resources that can withstand thresholds greater than 100 kRAD.

Single-event upsets (SEUs) come in different forms: latch-up upset, configuration upset, data upset in flip-flops, data upset in SRAM, clock upsets, transient in combinatorial logic and mathblocks, and upset in phase-locked loops.

One of the most significant SEEs is the configuration upset. Flight-critical or mission-critical applications require FPGAs to retain their configuration in radiation environments. Microsemi’s flash-based FPGAs, including RTG4 and RT ProASIC 3, exhibit a complete absence of radiation-induced upsets in the flash cells, which control the configuration of the FPGA. This is in direct contrast to SRAM-based FPGAs, which exhibited configuration errors. These SEUs cause the FPGA to change their function and behave unpredictably.

Mitigation of configuration upsets is very complex and cumbersome in SRAM FPGAs and not wholly effective, because mitigation schemes work by overwriting a corrupted configuration bit with a correct configuration bit. The corrupted configuration bit causes device malfunction from the occurrence of the single event until it is corrected—a period of at least several hundred milliseconds. During this time, the corrupted device will behave erroneously and pour erroneous data into the system.

The RTG4 FPGA has been tested to an extremely high energy level (103 MeV-cm2/mg) and exhibited complete immunity to configuration upsets. Microsemi’s website has a detailed breakdown of each type and how the RTG4 is hardened by design against them.

Wong: What advantages does the RTG4 provide compared to a radiation-hardened ASIC?

O’Neill: All ASICs have an upfront NRE, which must be paid whether or not the ASIC design is successful. If the ASIC design needs to be iterated (due to a bug or specification change), then a portion of the NRE must be paid again. The project must wait while the ASIC vendor produces the revised version of the ASIC. The risk of incurring additional NRE charges combined with the risk of schedule delays make ASICs a very unappealing choice for space designs. FPGAs such as the RTG4 offer much more flexibility and much less risk.

Wong: What advantages does the RTG4 provide compared to other FPGAs?

O’Neill: The RTG4 has more registers, more multiply blocks, and more transceivers than any other FPGA screened for space applications. Compared to FPGAs not screened for space applications (SRAM FPGAs), the RTG4 has robust flash configuration cells that are immune to configuration upsets in space radiation. This means that no background scrubbing or reconfiguration of the FPGA is needed, thus mitigating changes in configuration due to radiation effects. Data errors due to radiation are mitigated by the hardwired SEU-resistant flip-flops in the logic cells and in the Mathblocks.

Single-error correcting, double-error detecting (SECDED) protection is optional for the embedded SRAM and DDR memory controllers. This means that if a one-bit error is detected, it will be corrected automatically. Errors of more than one bit are detected only. SECDED signals are brought to the FPGA fabric to allow the user to monitor the status of these protected internal memories. Many of these options are not available in FPGAs not designed specifically for radiation environments.

Wong: What kind of support do you have for development?

O’Neill: The RTG4 family of FPGAs is supported by Microsemi Libero SoC design software that guides the user through the FPGA design flow. It provides seamless design-tool integration as well as project, data file, and log file management.

The RTG4 development kit gives space customers an evaluation and development platform for applications such as data transmission, serial connectivity, bus interface, and high-speed designs. The development board features a RT4G150 device offering 150,000 logic elements in a ceramic package with 1657 pins.

RTG4 also has PROTO FPGAs that offer a development and prototyping solution usable for development and final timing validation of space-flight designs. The RTG4 PROTO units use the same reprogrammable flash technology as the flight units. The PROTO devices can be reprogrammed many times without removing them from the development board. They have the same timing attributes as the RTG4 flight units, including support for the same speed grades as the flight parts. The RT-PROTO units, which are offered in non-hermetic, ceramic packages, are electrically tested in a manner to guarantee their performance over the full military temperature range.

These PROTO units are not intended for space flight. They offer no guarantee of hermeticity and no Mil-STD-883 class B processing, which is the minimum recommended for space-flight qualification. The PROTO FPGAs offer an alternative for development and preliminary testing before actual space-flight part testing.

Wong: What other space products does Microsemi offer that complement the RTG4?

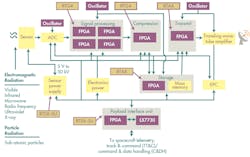

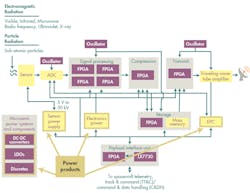

O’Neill: Microsemi has one of the industry’s most comprehensive portfolios of space products, including thousands of highly reliable standard and custom radiation-hardened dc-dc power supplies with a full line of electromechanical relays qualified for space applications to support power systems. Other products include precise timing and frequency solutions with ovenized quartz oscillators, and hybrid voltage-controlled and temperature-compensated crystal oscillators.

Additionally, the new Space System Manager family integrates commonly used mixed-signal satellite functions into a single space-saving IC. Examples include the the LX7720 for power drive or motor controller and the LX7730 for telemetry controllers. Microsemi also provides other mixed-signal ICs, MOSFETs, diodes, transistors, RF components, and custom solutions. Figures 3, 4, and 5 show other Microsemi products that complement the RTG4.

Wong: Space programs sometimes take years to complete. How long can I expect production to last? What kind of support do you have for legacy products?

O’Neill: Microsemi is proud to say that our FPGAs have a very long lifespan—introduction to last-time buy is upwards of 20+ years. Microsemi SoC product obsolescence policy is 18-month notification with at least 12 months’ notice before requiring final orders. For our constantly improving software, we provide earlier versions for consistent development environments should you need it. We also provide information on the accumulated life-test data for each version of programming software.

This file type includes high resolution graphics and schematics when applicable.

About the Author

Ken O'Neill

Director of Marketing, Space and Aviation, SoC Products Group

Ken O’Neill, Director of Marketing, Space and Aviation, with Microsemi’s SoC Products Group, has supported FPGA applications in space, aviation and other high-reliability markets for 25 years. O'Neill originally joined Microsemi in June 1990 as a Product Marketing Engineer and has held several marketing and field applications engineering positions. Before joining Microsemi, O'Neill served as a Design Engineer with Hewlett-Packard's Computer Peripherals Group. Prior to that, he was a Design Engineer with Racal-Comsec Ltd. O'Neill holds a Bachelor's degree in electronics engineering from the University of Reading, England.

William G. Wong

Senior Content Director - Electronic Design and Microwaves & RF

I am Editor of Electronic Design focusing on embedded, software, and systems. As Senior Content Director, I also manage Microwaves & RF and I work with a great team of editors to provide engineers, programmers, developers and technical managers with interesting and useful articles and videos on a regular basis. Check out our free newsletters to see the latest content.

You can send press releases for new products for possible coverage on the website. I am also interested in receiving contributed articles for publishing on our website. Use our template and send to me along with a signed release form.

Check out my blog, AltEmbedded on Electronic Design, as well as his latest articles on this site that are listed below.

You can visit my social media via these links:

- AltEmbedded on Electronic Design

- Bill Wong on Facebook

- @AltEmbedded on Twitter

- Bill Wong on LinkedIn

I earned a Bachelor of Electrical Engineering at the Georgia Institute of Technology and a Masters in Computer Science from Rutgers University. I still do a bit of programming using everything from C and C++ to Rust and Ada/SPARK. I do a bit of PHP programming for Drupal websites. I have posted a few Drupal modules.

I still get a hand on software and electronic hardware. Some of this can be found on our Kit Close-Up video series. You can also see me on many of our TechXchange Talk videos. I am interested in a range of projects from robotics to artificial intelligence.