This file type includes high-resolution graphics and schematics when applicable.

Rechargeable batteries have a great impact on the performance of electric vehicles because they eventually determine their driving range. To maximize cell life in a battery pack, it is important to understand the behavior of Li-ion batteries and the alternatives available for battery-management systems.

Rechargeable lithium-ion batteries, for example, are frequently used in electric vehicles. Compared to other batteries, lithium-ion batteries have higher energy density, higher cell voltage, and low self-discharge. The following factors each impact the performance of Li-Ion rechargeable batteries.

Cell Performance

Charging a battery to a 100% state of charge or discharging it to 0% state of charge degrades the life of a battery. The capacity of a battery cannot be considered the only characteristic that will maximize the battery’s performance. Aspects like longer battery life and the number of charge cycles, for example, need to be considered when designing high-performance rechargeable batteries.

Power Loss

During the lifetime of a lithium-ion battery, there will be inevitable power losses. Some of the factors are:

Self-discharge: After a full charge, a lithium-ion battery’s inherent self-discharge is about 5% of its capacity in the first 24 hours. At higher temperatures (more than 20oC), self-discharge losses increase. The self-discharge of a battery increases with temperature, age, and usage.

Internal resistance: Charge-discharge cycles eventually reduce the battery’s active material and cause other chemistry changes, resulting in increased internal resistance and permanent capacity loss. Cell aging results in an increase of the internal impedance of the cell, thereby affecting its ability to perform because of poor conductivity.

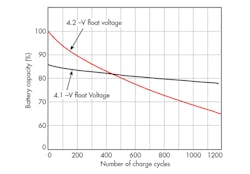

Voltage: Most lithium-ion cell packs have a float voltage of 4.2 V as the best balance between capacity and cycle life (Fig. 1). In contrast, a single battery has a voltage of 3.6 V (average voltage at discharging state). When the battery is maintained for long periods of time at 4.2 V or very close to 100% state of charge, however, capacity loss will occur and the lifetime of the battery will shorten.

Battery Balancing Techniques

There are no two exactly equal lithium-ion cells. Thus, the weakest cell in a battery pack limits the performance of the overall pack. Once the weakest cell reaches state-of-charge limits, the whole battery pack stops charging.

To maximize cell life and avoid battery stack failure, the state of charge of each cell must be constrained by accurately measuring the voltage of each cell with the assistance of a battery management system. This might include balancing to maximize the life of a battery pack by preventing the weakest cell from being overcharged or over-discharged. Engineers use different techniques to keep a balanced battery pack using passive balancing and active balancing.

• Passive balancing: Energy is removed from the most charged cell and is wasted as heat, usually through resistors.

• Active balancing: Energy is transferred between cells, usually through dc-dc converters.

Automotive Battery-Management Systems

An electric-vehicle battery pack contains dozens of battery cells configured in series that handle high power and high energy capacity within a limited space. Among other factors, automotive battery management systems need to handle electrical noise systems and the wide operating temperatures generated by electric vehicles.

Battery-management systems are designed using a wide range of functional blocks, different architectures, and ICs that can be created to optimize battery performance. Some common functional blocks are field-effect transistor (FET) drivers, fuel gauge monitoring, cell voltage monitoring, and temperature monitoring.

Some solutions require microcontrollers and some others run independently. Let’s look at these two products as examples of battery management systems: a high-voltage battery stack monitor by Linear Technology and a 16-cell battery monitor with passive cell balancing by Texas Instruments.

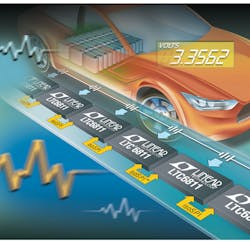

Linear Technology’s latest high-voltage battery stack monitor is the LTC6811 (Fig. 2). The LTC6811 enables high reliability, high stability, and high measurement accuracy systems through the inclusion of internal diagnostic capability to verify proper operation such as open wire detection between battery and monitor, auxiliary voltage reference to confirm primary reference accuracy to within +-5mV, and dual-channel measurements to confirm multiplexer and ADC accuracy to within 0.01%.

LTC6811 also supports ISO 26262, a standard that defines automotive functional safety. ISO 26262 provides a framework for developing and validating automotive products that are safe from electronic and electrical system malfunctions, including automotive BMS malfunctions.

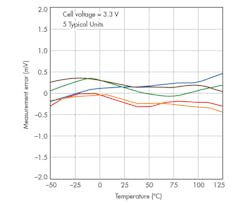

The LTC6811 can measure up to 12 series-connected battery cells at voltages with better than 0.04% accuracy (Fig. 3). Integrated into the LTC6811 is a 2-wire isoSPI for high RF noise immunity to 1 Mbps and up to 10 meters of cable. The LTC6811 offers both active balancing and passive balancing. It includes internal passive balancing field-effect transistors (FETs) that can discharge individual cells or directly control larger high-power external FETs. The LTC6811 can be configured to discharge cells while in a low-power state, such as when the battery pack is at rest.

“Accuracy is the most important aspect of a battery-management system because the state-of-charge needs to be constrained. It is necessary to have a flat voltage charge/discharge curve in the usable discharge range,” says Linear Technology’s senior product marketing engineer, Gregg Zimmer, who also highlighted the presence of a sub-surface Zener reference in the LTC6811to provide stability and accuracy by constantly measuring each cell’s voltage within less than 1.2 mV of error.

Texas Instruments offers the bq76PL536A-Q1 designed for high-reliability automotive applications (Fig. 4) for protection against over-temperature, over-voltage, and under-voltage. The bq76PL536A-Q1 is an integrated 16-cell monitor that provides pins for direct drive of external N-FETs for passive cell balancing with power resistors.

It is intended to be used with a host controller to maximize the functionality of the battery-management system. The bq76PL536A-Q1 offers high accuracy analog-to-digital (ADC) with 14-bit resolution with internal reference and it is able to communicate with a host microcontroller via a high-speed universal asynchronous receiver/transmitter (UART) interface.

The device contains user selectable self-test features to diagnose functional blocks within the device, such as automatic shutdown in the event of over temperature, calibration integrity, and so forth. The bq76PL536A-Q1was not developed in a manner to meet all ISO26262 specifications but it can still help customers meet functional safety standard requirements through built-in self-tests to validate defined internal functions.

As we can see from these products, each of them has different protection features. There are products for every costumer need and after all it is up to the costumer to decide which battery-management system works best for them.

Envisioning the Future

“The constant advances in power electronics and the tremendous interest of several vehicle manufacturers in electric vehicle, together with the constant development of battery chemistries and battery management systems, will certainly improve the efficiency of batteries and help the rise of the electric vehicle market,” says Zimmer.

Battery performance is a fundamental ingredient in the success of electric vehicles. Researchers keep looking for better battery chemistries that could help improve battery life and the number of charge cycles to design high-performance rechargeable batteries. Power electronics will keep advancing while battery management systems will benefit from the latter. Automotive battery-management systems will continue to work on maximizing driving distances and life time for battery packs.

About the Author

Maria Guerra

Power/Analog Editor

Maria Guerra is the Power/Analog Editor for Electronic Design. She is an Electrical Engineer with an MSEE from NYU Tandon School of Engineering. She has a very solid engineering background and extensive experience with technical documentation and writing. Before joining Electronic Design, she was an Electrical Engineer for Kellogg, Brown & Root Ltd (London. U.K.). During her years in the Oil and Gas Industry she was involved in a range of projects for both offshore and onshore designs. Her technical and soft skills bring a practical, hands-on approach to the Electronic Design team.