This file type includes high resolution graphics and schematics when applicable.

Most consumer electronics products rely on power-management integrated circuits (PMICs). As those consumer devices evolve, designers face the constant challenge of trying to reduce board footprint and decrease power consumption. Over the years, programmable analog devices like field-programmable analog arrays (FPAAs) have been used very successfully. Now, a new developer called AnDAPT is paving the way toward customized, integrated power-management solutions. I think AnDAPT’s AmP technology will disrupt the power-management semiconductor market, as AnDAPT offers programmable solutions with analog proficiency to customers producing units at any volume. I also asked another expert to weigh in on this new technology and the reasons for potentially disrupting the PMIC market.

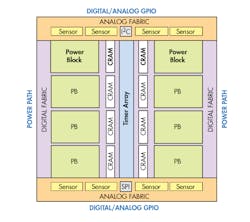

AnDAPT claims that its on-demand power-management technology can be configured exactly to the power characteristics of a particular system without worrying about analog issues, such as varying interface voltage, interface current, noise, and impedance matching. Its solutions use analog power blocks with scalable integrated MOSFETS (SIMs) to increase current capabilities. These analog power blocks are called Adaptive Multi-Rail Power (AmP) platform ICs; they are interconnected with digital circuitry in a way comparable to field-programmable gate arrays (FPGAs). Because of the digital interconnect fabric, AmP platform ICs can be configured precisely to the power characteristics of a particular system.

AnDAPT’s solutions are not only available for enterprise solutions with high shipment volume, but also relatively low-volume end products like medical devices and PCs. AmP platform ICs can substitute power-management devices, such as buck regulators, boost regulators, low drop-out regulators, load switches, controllers, etc. “Fundamentally, AmP platforms implement most functions in analog (µAnalog) implementation as is done in analog catalog devices. Therefore, they have similar performance characteristics as custom analog designs,” says AnDAPT’s president and CEO, Kapil Shankar.

“For example,” he adds, “we do not require a faster digital clock, as most ASIC digital power implementations do. Therefore, our bias currents are in the very low tens of µA range, delivering us some of the best peak efficiency performance (e.g., our peak efficiency numbers are close to 95% for 6.0-to-3.3-V conversions). Our process MOSFET figure of merit is 75 nC*mâ¦, which is in line with the best in our industry.”

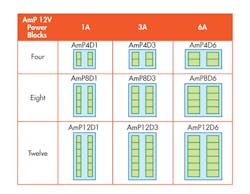

The AmP devices are supported by the WebAmP development software, which is cloud-based. The inclusion of more analog functions and capabilities can be handled with Verilog code. Users can drag-and-drop power components from the pre-built library based on their application rail requirements. For an example, take a look at AmP8DS6 platform to see how you can drag-and-drop components (Fig. 1). AnDAPT’s first devices are part of a 12-V family of nine members with three selections: four, eight, and twelve power blocks of 1A, 3A ,and 6A current capacity each (Fig. 2).

AmP devices can provide telemetry via built-in PMBus over I2C. In addition, the serial peripheral interface (SPI) can be used for device configuration. Users can also run power analysis to optimize an AmP design by using the LC calculator, stability analyzer, PID tuning, transient response calculator, etc.

Shankar notes, “Additionally, we undertake the same level of testing as our competitors. And even though we have a different architecture, we benchmark ourselves based on industry-accepted performance metrics regarding efficiency, dynamic performance, and static performance. We have also already passed extensive VRD testing at the top data-center processor vendor.

“All vendors have their own certification testing classified in five areas of regulation, transient response, startup, shutdown, and protection testing,” Shankar says. “We have ourselves conducted extensive testing for our power components in each of these areas. We implement telemetry using standard PMBus standard. We will also look at standards such as DOSA over time as we develop our technology further.”

In the future, AnDAPT will include the AmP 60-V family supporting an input voltage from 24 to 60 V, the AmP 5-V family supporting an input voltage from 1.8 to 9 V, and the AmP 110-V family supporting an input voltage of 110 V. Also, AnDAPT is expecting to complete ISO90001 by Q2 next year.

“The certifications are usually done by our end customers,” says Shankar, “but we do undertake silicon qualification using processes accepted in the industry. Qualification for the technology, product platform, and package is done with standard testing for HTOL, high-temp cycling, HAST, high-temp storage, ESD, latch-up, etc. We expect qual completion in the first quarter of 2017.”

AnDAPT is not the first company digitizing power analog devices. Companies like Silego and Anadigm offer not only power-management solutions, but mixed-signal solutions and more. But I think AnDAPT’s AmP technology will disrupt the power-management semiconductor market, as AnDAPT offers programmable solutions with analog proficiency to customers producing units at any volume. Such an approach certainly can aid in saving time, reducing board footprint, and lowering costs.

Richard Wawrzyniak, principal analyst, Semico Research Corp., notes the reasons for this trend:

“It is well known that the need to fill data centers with multiple processors, more storage, and higher-performance networking is ever increasing. These needs push against constraints imposed by power costs and more importantly pre-existing power frameworks. The primary driver for this solution therefore is the need for control, telemetry, and management of power delivered/consumed by every processor, logic, memory, and storage device and, therefore, every silicon device in a data center. The existing solutions rely on a majority of discrete power devices with a limited or very low cost-effective power-management capability. In other words, no custom PMICs are available, as the rail requirements are too diverse and limited opportunities exist for volume aggregation to amortize custom PMIC NRE. The AnDAPT solution, because it is an off-the-shelf solution, offers an ability to build a cost-effective custom PMIC for all these silicon types, regardless of volume, enabling the ability to provide management capabilities and lower power consumption.

“The AnDAPT solutions also deliver lower cost compared to discrete POLs, integration for smaller board footprint to make space for other components, and lower inventory costs for 12 V dc-to-dc step-down regulator applications. AnDAPT’s roadmap shows future direction to include 48 to 60 V multi-rail power (AmP) platforms enabling the same benefits for intermediate-rail 48 V dc-to-dc step-down regulators’ applications.”

Wawrzyniak concludes, “The AnDAPT solution allows for a consolidation in the number of different discrete PMIC solutions a designer must deal with in his approach to creating and distributing a multitude of power rails around his system. Since the AnDAPT devices are programmable, a single device type can stand in for many different discrete types of PMICs and still meet the designer’s requirements. This in turn reduces the number of different part types a designer must deal with and reduces inventory costs and delivery times. In essence, designers can have a custom solution for very close to the cost of an off-the-shelf part with all the flexibility that comes from such a technology—A very powerful combination in today’s marketplace.”

Do you think AnDAPT’s µAnalog devices could perform as well as analog power components?

About the Author

Maria Guerra

Power/Analog Editor

Maria Guerra is the Power/Analog Editor for Electronic Design. She is an Electrical Engineer with an MSEE from NYU Tandon School of Engineering. She has a very solid engineering background and extensive experience with technical documentation and writing. Before joining Electronic Design, she was an Electrical Engineer for Kellogg, Brown & Root Ltd (London. U.K.). During her years in the Oil and Gas Industry she was involved in a range of projects for both offshore and onshore designs. Her technical and soft skills bring a practical, hands-on approach to the Electronic Design team.