EnergyStar or no, power supplies deliver

Industry is abuzz over the Environmental Protection Agency's recent decision to “sunset” the Energy Star programs for external power supplies at the end of the year (Dec. 31, 2010). But make no mistake -- developers are still hot on delivering the lowest-loss designs across the board. The intent of all standards, declared and otherwise, remains the same: maximize efficiency and minimize standby requirements.

Power supply design is still about getting the most power out, but it's also increasingly about energy conservation. IC makers in particular have, in a sense, recast the power conversion issue. The goal today has as much to do with cutting wasted energy and dealing with heat dissipation as with delivering more raw power to the load. The principle plays out particularly in portables as the industry searches for better ways to economize on energy while charging a battery.

EPA's July announcement at the top of the news has the industry somewhat confused as to the future of some energy standards, but nothing has been lost. “We're confident that the effect of the Energy Star EPS (external power supply) standard will be sustained because many of the other standards remain in place,” said Ann Bailey, Chief of the Energy Star Labeling Branch, citing the existence of federal minimum efficiency standards for EPSs. “It's not quite as stringent as Energy Star, but it establishes a floor, which is very important. We also have product-specific performance specs for a long list of products that use external power supplies and those will continue to require EPSs that are as efficient as (directed in) our old specification.”

EPA's intent is that so-called Level V EPSs as designated under the International Efficiency Marking Protocol will become the de-facto substitute for those supplies qualifying under the old Energy Star 2.0 EPS spec. “Levels I through V corresponds to a different level of energy efficiency and our Energy Star requires an equivalent of Level V. This marking system will remain,” says Bailey. With the major efficiency issues aside, specific other details with respect to such parameters as the 0.5-W standby power proposal for the larger supplies are not yet clear. But Energy Star v. 2.0 EPS is a voluntary spec and thus no contentious issues are foreseen.

It won't be the first time a major voluntary spec has been withdrawn. “It doesn't happen very often,” says Bailey, “but as we get to a point where it doesn't appear there are additional efficiency issues to be gained, then we “sunset” it. We did that, for example, with LED traffic signals and transformers, not your average consumer products. We actually “sunset” the specification for cable boxes at one point, but we're revisiting that now.”

But it doesn't mean the old standard is obsolete. “It's because its mission was accomplished,” says Bailey, “and we don't expect anything to fall back to what it was because this spec has gone away. This is a great story about how two agencies can work together and government sort of functions ideally. We had an initial impact on the voluntary side. Because of that impact, DoE was able to establish a standard and then we were able to further move the market and the standard stayed in place. Once there's a minimum efficiency standard, there's no backslide.”

Meanwhile, there's a move afoot to appoint third-party organizations to confirm claims for compliance with various existing standards by supply manufacturers. Amid some contentious issues — including a study in 2007 of EU and U.S. customers as to their trust in claims from both business and government -- UL Environment (ULE, Northbrook Illinois) has recently been certified as the newest third party to confirm Energy Star claims.

Continue to next page

“It's one thing to come out with regulations,” says Mohan Mankikar, president of Micro-Tech Consultants (Santa Rosa, Calif.). “But the testing equipment has to perform some exacting tests, and test procedures are complicated. UL has the expertise to do this job.” Although perhaps moot at this point, ULE announced in June that Delta Electronics' Model 1429 ac/dc supply was the first from a Taiwan-based company to earn validation per Energy Star's v. 2.0 EPS standard for external power adapters.

Power-train focus

If you simply want 95% efficiency from most power supplies, it won't be much of a problem — such supplies are all around. But it still takes some doing to hit such levels in an ultra compact size, with fast transient response for the lowest output capacitance, at high power. As well, many designs strive to deliver high efficiency over the widest range of loads for the highest input-output voltage difference, at the lowest cost. Ultra efficient sources are entirely within the capabilities of existing silicon technology. (The market has yet to accept silicon-carbide and gallium-nitride component technologies.) But it's also true that the individual components — starting from the most critical one, the power MOSFET output stage — as well as design optimization techniques as a whole can be and are getting better.

System designers in addition have access to a slew of new controllers to meet the ever-changing demands and parameters well beyond the incremental improvements in MOSFETs, topologies, and higher switching frequencies.

Increasingly, each system building block gets scrutinized for power losses. Mainstream strategies for minimizing waste energy include keeping system voltages as high as possible before stepping them down as a means of minimizing I2R and transmission losses; and maximizing system efficiency by intelligently spreading system losses.

Improvements come hard in supplies that are already efficient. Power-wise, if you want to boost efficiency from 95 to 96%, you need to cut 20% of your losses. To do so, you need the right part in the right place. “It's a roundabout way of saying the best topology in the world won't help you if you have bad components, and the best components won't help if you've got a bad topology,” said Steve Oliver, marketing and sales VP for V-I chip at Vicor (Andover, Mass.). “You really need to choose the right topology to get the most bang for the buck for whatever components you use.”

In mobile applications, the capabilities of the monolithic buck converter are beginning to level off. The old formula of operating at ever higher switching frequencies as a means of boosting efficiency is reaching the law of diminishing returns. Vendors have developed new switching topologies to address more stringent accuracy and voltage regulation challenges.

Continue to next page

These same strategies, as well as architectures in larger systems that take 48-V levels down to low voltage for distribution, have improved power density in supplies suited to server/processor applications. Such applications include Intel's VR12 standard, wherein the power supply may be called on to deliver more than 100 A at 0.15 V.

The power MOSFET stage remains the most critical part in most every supply, big or small. “The control loop in the mobile world accounts for a pretty small percentage of total power, e.g., 7 mA control current versus a 600 mA load,” says Peter Khairolomour, technical marketing manager, mobile power, at Fairchild Semiconductor (San Jose, Calif.). “Control isn't a big piece of the efficiency game. In mobile power, for controllers I think it's a wash among suppliers. The FET's RC factor -- i.e., how much capacitance for RDS on -- tends to be a differentiating factor.”

The supply power train (driver-MOSFET) consumes about 70% of all losses in IC-based designs (followed by 15% for a supply's output inductor and 5% for its controller). But FET makers continue to improve on a component most users tend to believe is about as good as it can get.

Notable products include the CSD86350Q5D NexFET power block device from Texas Instruments for telecom, computers and single-phase applications at a nominal 25 A. “It's two FETs in a package atop each other,” says Chris Bull, power marketing manager, drawing the distinction between two-FET products that are side-by-side on the die. “By putting FETs atop each other, we gain use of the x, y, and z dimensions, thus getting better power density. In a half-bridge buck converter, we stack FETs to get rid of stray inductance and parasitic capacitance that would otherwise restrict the silicon dc/dc performance. It has half the gate charge for the same resistance, and so we have half the switching losses. In a 12-V in, 1.3-V out converter, the NexFET gives us a 2% gain in efficiency. So we can get 25 A at 90% efficiency in a 5 × 6-mm device. It's as good as two discrete devices.”

Other arrivals include International Rectifier's (El Segundo, Calif.) expanded portfolio of mid-voltage Hexfet devices for both ac/dc and dc/dc applications, now in a PQFN package. “There's no top side cooling in this design,” said Stephane Ernoux, power management device marketing director.

While all supply designs try to be as efficient as possible, other design objectives depend on the target application. “In our work (portables), everything is monolithic,” said Peter Khairolomour. “Except the controller and bandgap. We use 0.5-, 0.35-, and 0.18-micron technology. We had one of the first high-efficiency 3- and 6-MHz switchers. Our customers knew there was going to be an efficiency hit by going from 3 to 6 MHz. (And it's here where the industry has more or less settled on the laws of diminishing returns.) Above this point, the size-versus-efficiency gains are not linearly related.”

Optimization proceeds by balancing switching losses versus dc losses. One can make the FETs larger, but in turn that requires a higher capacitance for minimizing switching losses on the gate (6 MHz, PWM mode). Optimizing the PFM (pulse frequency modulation) mode is a different story, and becomes a question of the quiescent bias current at light loads. The tradeoff becomes one of bias current versus transient response.

Continue to next page

Fairchild addressed some of these issues by going with a hysteretic (nonlinear) architecture, which for a given level of quiescent current (IQ) has a much faster control loop for quick changes in operating current. “We're seeing 15 to 16 µA, phenomenal when you consider we can still support zero to 600 mA load swings, which is considered quite a bit for mobile,” says Khairolomour. “This is using super-low-cost 0402 caps. Optimizing how much current in the current mirrors, bandgaps, and so on, these increments add up to 10 to 15 µA of savings on IQ. That's how we bring light-load efficiency up and standby power down.”

One evolving issue in the mobile space has to do with replacing the low-dropout regulator with buck converters in powering higher-voltage rails for applications that address 0.8- to 1.2-V cores and various associated transient events. LDOs (low drop out linear regulators) tend to be more efficient when their voltage is higher. Nominal battery operating voltages in portables are at 3.7 V. SD Flash memories in cell phones require a nominal 2.9 V (2.7- to 3.6-V range), says Khairolomour, and power drain is growing because of larger memory sizes. Battery designers also need to meet the call for operating at the lower end of its voltage spec. The conversion efficiency in going from 3.7 to 2.9 V is about 80%. How can one improve on that?

Fairchild's new FAN5362 buck converter, which approaches 94% efficiency in that application, operates in a so-called quasi-switching mode at low voltage. When the battery voltage drops to 3.1 V, the converter dumps energy from input to output. The typical buck converter will have undershoot, and there's often some instability for several microseconds. To get around it, the FAN5362 quickly goes from the switching to a quasi-linear state, then back to the switching mode when the transient clears.

Other new dc/dc entries include the FAN4603 micromodule for portables, which Fairchild touts as the smallest fully-integrated, plug-and-play buck converter in the world. It measures 2.5 × 4 mm.

Mid-range dc/dc issues

The various architectures come with tradeoffs. Integrated power chips as well as power-train blocks drastically improve response by cutting parasitics on the circuit board, although with a sacrifice of flexibility because of the integrated solution. To get the best efficiencies at the “discrete chip” level, a system designer ideally buys a driver, controller, and hand-picks his power FETs.

“Efficiency is a key goal, but not to the exclusion of everything else,” notes Don Paulus, vice president and general manager of D Power products for Linear Technology (Milpitas, Calif.). “People still need certain form factors. The emergence of driver-MOSFET products and power blocks addresses the efficiency issues but also addresses power density constraints. Our LTC3860 is a high-performance controller. It doesn't have an integrated power train. It does not have its own driver so it can work with the various power train components available.” As such, the LTC3860, which handles a wide range of switching frequencies, allows the designer to make a tradeoff between efficiency and size. “It also does a good job sharing current for multiphase solutions, which is one of the difficulties when you use these types of high-transient-response architectures,” says Paulus.

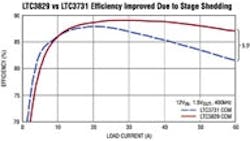

Multiphasing techniques maintain high efficiency over a wide range of changing loads but, “The issue is that the switching losses, depending on the duty cycle and input and output voltages, can actually dominate compared to the resistive losses in the power FETs,” says Paulus. “So when you back off the maximum current points, you must address those transition gate-charge losses. You do that by turning off phases as you go to lighter currents. When you go below 100 A, say, your losses will be dominated by the switching losses. If your controller can sense the lower current level and turn off the appropriate number of phases, you save switching losses.”

Continue to next page

Two products from Linear -- the LTC3829 step-down dc/dc (single output) for three-phase applications, and the LTC3856 two-phase device - are designed to adjust their phases this way. They include a burst mode to further lighten the transition losses.

New “half-chip” pre-regulator modules (PRMs) from Vicor are part of the company's factorized-power architecture (FPA) system for overcoming the size, speed and efficiency drawbacks of traditional standalone dc/dc power conversion problems.

These problems include those that arise in doing a one-step conversion from 48 V down to a few volts. They also boast an efficiency of 97%. “Its density is 1,300 W/in3, probably four times more than anything else out there,” said Steve Oliver. These devices, which occupy a half-inch of area on a printed circuit board, are suited for Intel VR12 board-level computers and for large-scale LED lighting applications for municipal applications (town halls, the cinema, libraries, and parking garages).

The half-chips are billed as a game-changing part for people in the telecom and test industry. “The original V-I Chip range (2005) was in a 1-inch size, 320 W in a 1-inch block, 100 A coming from a current multiplier. Now it's 400 W in the same package, and 200 W for the half inch,” says Oliver. Improvements include new magnetics, better PCB performance, some tweaks in the FPA's buck-boost topology, and some new control ICs and MOSFETs (those from Fairchild, ST Micro, Infineon, International Rectifier, Great Wall Semiconductor are used). Oliver points to the V-I chip's extreme trim range: from 55 to 5 V at a nominal 48 V. “Combine it with a current-multiplying unit (voltage transformation module, VTM), it can deliver 100 A at 0.15 V. We're far ahead of Intel roadmaps. It's a future-proof part in a high-efficiency, small design,” he says.

AC/DC supply issues

Even with Energy Star bowing out of power supplies, supply efficiency isn't likely to suffer. “Depending on power level, you're going to get anywhere from 75% to 95% efficiency from an ac/dc supply,” says Aung Tu, product line director for power conversion at Fairchild Semiconductor. Fairchild's FAN9612 interleaved PFC controller, employing the boundary conduction mode (BCM, as opposed to continuous conduction mode, CCM) allows using less expensive diodes at up to 800 W without sacrificing efficiency. Another new PFC controller, the company's FAN7930, applies to narrow-input boost applications that operate in the critical conduction mode (CRM). This part cuts third-order harmonics (THD) down to 3%. Fairchild's newest controller for CCM PFC applications, for 300 W to 2 kW designs, is the FAN6982.

“IBM asks 95% for their servers. They're talking about kilowatt power supplies,” says Aung Tu. “But at low power, where there is no PFC(power factor correction), even the Energy Star spec has a calculation factor where they're looking at just 75 to 80%.” But that, he says, doesn't mean it's necessarily more difficult to get higher efficiency in an ac/dc supply. Indeed, flyback designs, zero-voltage switching and higher end topologies aren't worth the effort for lower-power applications such as wall adapters and similar devices.

With supplies for servers, though, 95% is often the goal. “We're pushing subswitching topology to extend the power range,” said Helen Ding, applications engineer for ac/dc power converter products at International Rectifier. “Synchronous rectification can easily increase efficiency 1 to 2%. But it's not easy to reach 90 to 95% with most technologies. The half-bridge on the secondary side with continuous conduction mode (CCM) operation can help us get 95%. That's high, but beyond that, it's pretty hard to increase the efficiency a half percent or one percent more.” IR's more recent arrivals for secondary-side synchronous rectification include its IR11672A SmartRectifier for driving N-channel MOSFETs in resonant half-bridge converters.

Continue to next page

Ironically, saving power at the lowest levels (i.e., standby) for higher power supplies is becoming somewhat of a defacto obsession in the ac/dc arena. Energy Star v. 2.0 for EPS, a voluntary spec that became official in November 2008, calls for 0.5-W standby power, half that of previous version (1.1). It's not a problem for lower-power supplies. Phihong USA and Extron's PS Series of desktop power supplies (in the 30-W region), for example, have been among the earliest to comply. Cutting 500 mW from the previous standard, however, looks to be a more formidable task for the larger supplies (up to 250 W). One of the main issues is how to do it above 75 W, where a PFC front-end is required. A few solutions are expected next year for supplies rated above 75 W, with much of the industry somehow expecting defacto compliance to the voluntary standard by 2013.

The “gotcha's” of dc/dc design efficiency

One way to successfully address dc/dc designs is to be specific in defining the problem, says Deepak Savatti, executive director for the multiphase product line at International Rectifier. “What portion of the efficiency of the chart are we talking about? Light load, peak efficiency, full load? All of it? It depends on the application.”

Indeed, optimizing the efficiency at a particular load point, i.e., efficiency shaping, is becoming more critical. “What does the CPU look like in that server, what kind of load profile am I going to see? For VR11.1----it's a 130 W processor, at 1 V it's 130 A,” says Savatti. “Your CPU is operating at 50 to 60 A most of the time. But if your dc/dc is most efficient at 130 A, it's not going to help you. You want to be able to address the need of the load where it's operating most of the time.”

Indeed, today's energy-efficiency specs call for the designer to meet minimum efficiency requirements at the 20%, 50%, and full-load points. Customers almost unanimously ask for high peak efficiency, followed by high efficiency at light load, followed by high full-load efficiency. Peak efficiency is usually desired at 50% of the load.

“Peak efficiency for us generally happens at 60 to 75 A (3-phase applications), where the CPU is a lot of time. So we're at 80% of the load half of the time,” says Savatti. Typically, a 3-phase app, 150-A CPU application might yield a peak efficiency approaching 95%. But it's important for the system designer to play close attention to specmanship. “When people talk about efficiency, what are the losses included? One of the problems I see is that the high-efficiency claim usually doesn't include the inductor losses, the trace losses, or if there is a load line. If you don't have a load line in an efficiency measurement for a processor, you'll misstate your efficiency. So all these little tricks in stating efficiency, it's not an apples-to-apples comparison.”

Beyond that, most designers don't appear to have a good feel for the individual parts of the system. “Let's say you vary your switching frequency. Then you're forced to put in a different inductor (smaller for higher frequencies)”, says Savatti. “So that will move your efficiency range a bit. You can tweak the efficiency by altering the gate drive for the high side FET/low side FET and so on. In any case, sooner or later we'll see the limits of today's inductors. The inductor is one place where we haven't done a good job. The inductors today have a nominal dc resistance (DCR) of 0.29 milliohms. Which is pretty high because we're getting to the limits of what we can do with low gate-charge as well as RDS, maybe about a milliohm for 40 amps of continuous current. Those are tremendous improvements in device physics, but we can't get that same rate of improvement. We're now trying to approach it with inductors that have a DCR of 0.2 milliohm. That means you're going to cut losses in an inductor by almost 25%.”

Thermal efficiency is yet another consideration. A given design might have good efficiency per se, but you might not be able to take advantage of it if thermal management is poor.

Digital developments

It took time to knock down the proponents of so-called “digital power” technology for medium and high-power applications. The point of contention pertained to “digital” being “faster” and “more accurate” when placed directly in the feedback loop of a power conversion stage. Those rather vague claims have receded, but digital power techniques still have a following, particularly as one easy way to improve the transient response, albeit indirectly, in multiphase architectures.

“The talk on digital control loops in dc/dcs has largely evaporated,” says Linear Technology's Don Paulus. “The argument on digital power is meaningful in power system telemetry to measure and monitor current and voltage levels, power loss, temperature and so on to optimize system level power efficiency and usage.” The view is fairly universal. “Digital is a buzzword; people have to be careful how to use the technology,” says Vicor's Steve Oliver. “Digital technology is excellent when it comes to communications---setting voltage, reading back system voltage, and control. But when it comes to power converters, it still comes back to the analog system. Anything's possible in time, but if you want the fastest, most accurate feedback loop, use an optosensor and an analog op amp. It's the most elegant way.”

“Digital feedback is much slower, much less precise than an analog feedback loop,” says Oliver. The ideal solution is to keep the analog loop the way it is, but add power management features----digital interface, gathering temperature, voltage, and current info, and feed that information back through a digital bus. Now the loop doesn't stay stable (with load variations) if you don't re-optimize the compensation. Doing that in analog is very difficult. Doing it with digital, you just change some internal coefficients. Internally, you have a look-up table that relates how many phases to the loop coefficients.”

And it's in the power management mode that digital power increasingly comes into play for multiphase applications. “The controller has little impact on efficiency,” says International Rectifier's Deepak Savatti. “But a digital controller gives you one advantage at light load: phase shedding. Phase shedding is independent of the power stage. You can do it automatically without decision-making (the controller is smart). If my output current is 50% of load, going from four to two phases improves efficiency by almost 5%. On the other hand, digital power has no impact on peak efficiency and full-load efficiency. But (indirectly), the transient response in a multiphase system is going to be better.”

More information:

Environmental Protection Agency, www.epa.gov

Fairchild Semiconductor, www.fairchildsemi.com

International Rectifier, www.irf.com

Linear Technology, www.linear.com

Micro-Tech Consultants, www.micro-techco.com

Texas Instruments, www.ti.com

UL Environment, www.ulenvironment.com

Vicor, www.vicr.com