2019 Special Report: Programmable power supplies & loads

Ever since manufacturers of electronic equipment, devices, and instruments mastered the production of safe and reliable products, they’ve been constantly pushing for increased efficiency. The demand for energy efficient programmable power supplies and loads has taken on heightened importance over the past decade as more and more vendors pursue “green” initiatives—not just because it’s good for the environment, but because it’s good for business. Application industries such as Mil/Aero, automotive, commercial, medical, and renewable energy require smaller and smaller form factors in programmable power supplies and loads while wanting better interface options, a wider selection of power-conversion products—all while minimizing ripple and distortion. Not an easy task for vendors of such products.

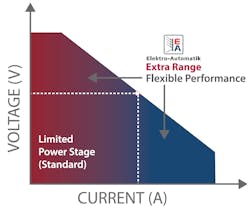

Providing historical context, Turner elaborated that power supplies traditionally were Si02-based, with typical switching frequencies of 25 to 35kHz. The low switching frequency, combined with low-efficiency switch devices, resulted in amplifiers efficiency in the range of 65 to 82%. Fast forward to now, newer generation power supplies from Elektro-Automatik are high switching frequency (150kHz) SiC MOSFET amplifiers.

Turner said another development is with moving control circuitry from analog to digital, elaborating that digital architecture using FPGA-based controls to the amplifier improves load regulation response and opens the door for additional features like arbitrary waveform generation and advanced measurements.

Vendors told EE that regenerative loads are quickly replacing traditional air-cooled or water-cooled loads that burn 100% of the loaded energy in the form of heat. Turner mentioned that regenerative loads return up to 95% of the loaded energy back to the localized grid, and that Elektro-Automatik has seen a significant transition in sales mix, as approximately 75% of customers are switching from the company’s air-cooled solutions to regenerative technology, especially in burn-in applications.

“Regenerative loads reduce energy consumption, cooling infrastructure cost and offer three to four times the power density of an air-cooled solution,” Turner said. “DC loads pack up to 15kW in a 3U, 19-inch rack mount solution. Regenerative DC load technology is much like a PV inverter which accepts DC voltage, which driven and converted through a DC-AC grid synchronized AC current source.” (Figure 1)

Looking historically again, 600 Vdc used to be considered high voltage for most applications. A good example is that both residential and commercial photovoltaic inverters (PV) operated from around 200 Vdc to 550 Vdc. As these inverters increase in power, the higher currents needed contribute to overall system line-loss efficiency.

“In the world of PV Inverters, efficiency is often the consumers’ deciding factor in model selection,” Turner said. “Over the last several years, the drive for high-efficiency infrastructure has driven PV inverter manufacturers to migrate to voltages as high as 1,500 Vdc. According to some reports, raising DC voltage to 1,500 volts can increase individual component costs by up to 40% but reduce overall system cost through fewer balance-of-system components and lower installation labor requirements. Elektro-Automatik is starting to see requests for voltages as high as 2,000 Vdc.”

End-users are asking to get more out of their power sources than ever. They want ease of integration that drives integration simplicity. One-way power supply manufacturers have addressed this requirement is through Integrated System capabilities. Turner explained that recently, DC power supply manufacturers are integrating high precision power measurement capabilities and arbitrary waveform generators into the supply.

“Today, a single power supply has the capability of replacing digital multimeters and do not require complex and sometimes expensive coupling networks to introduce ripple (dirty power) to test their products against emissions immunities,” Turner said.

Through these trends, power density remains an important factor in selecting a power supply. However, the technology may have reached the point of diminishing returns, as space-saving often means the density comes at a cost. Turner explained that as air-cooled power supplies need to push air across heat sinks, running as high as 95% efficiency since 5% is exhausted in heat.

“Fan sizes become so small that the auditable noise (dB) often impacts system operators and can exceed corporate and even OSHA guidelines for acceptable dB to employees,” Turner said. “Look at server farms that have screaming fans in a 1U (3.75-inch) chassis which require them to be stored in a controlled environment that includes noise reduction. One method to combat this issue is using variable speed fans, in which speed is driven by heatsink temperature vs. historical methods of adjusting fan speed based on output current or having the fans run at full speed while the supply is on.”

To respond to these trends and challenges, Germany-based Elektro-Automatik in February just introduced its SiC-based PSB 10000 4U Series, which is a 94%-efficient 30 kW supply and regenerative load in a single compact 4U (7-inch height) 19-inch racked mount solution.

“30kW used to require 6U, so this newer generation architecture is 50% smaller than previous generations,” Turner commented about the product. “This new series expands on our successful PSB 9000 3U solution into power levels of 1 MW. This solution bridges the gap between bi-directional applications that previously required a separate DC supply and DC load to deal with EUT’s, such as battery charging systems, onboard HEV/battery chargers, DC management systems, and energy storage devices. The PSB is a single solution that offers simplified integration and results in approximately 25% cost savings over separate instruments.”

One particular area of growth for Elektro-Automatik has been in eMobility applications, which include electric vehicle (EV) charging systems, battery cell production, HV-battery pack test, HV-switches, fuel cell production, DC power management, and energy storage devices.

“It’s simply not practical to use batteries for R&D or production so DC power supplies are used to accurately and safely control devices that are driven by DC technology,” Turner said.

What’s trending?

To take a deep dive into these trends in power supplies & loads Turner mentioned above and more, we at EE asked a pool of vendors to weigh in on their observations. Here’s what they told us.

“Another significant trend is the growth in applications for greater than 40V circuits. With more electrification of the automobile, automotive manufacturers are incorporating 48V bus circuits. in their new vehicles. DC-DC converters must drive 48V pumps, fans, starters, and generator systems. New server systems driving the cloud are becoming 48V-based including the cooling fans. Similarly, home automation and robotics circuitry are also using 48V. Large battery-operated devices such as chainsaws and other power tools are also using higher voltage, 48V to 60V, battery packs. Thus, 48V and higher output supplies are needed with more power.

“With more and more battery-powered, low power IoT products on the market, manufacturers need to get more information on battery life. Battery simulation is becoming more important. Supplies or sources that can model a battery and simulate a battery’s output can enable product designers to test their products while more efficiently emulating battery states such as near end-of-life.”

Steven Lee, application engineer at Keysight Technologies: “One of the hottest markets expected to grow in the coming years, is related to the automotive business, driven mainly by the electric car market. The high-power demands needed for EVs require high-power devices able to efficiently convert, regulate, and switch seamlessly large amounts of high voltage currents. New wide bandgap, SiC, and GaN-based devices are the preferred options compared to insulated gate bipolar transistor (IGBT) power devices, due to the benefits they offer, such as: High-temperature operation over 300°C; efficiency related to higher switching speeds; and high voltage operation withstanding voltages of more than 600V. Manufacturers need high power, high voltage, and current power supplies need to address these requirements.

“The next trend we see is related to cell testing, battery, and battery packs for large energy storage (e.g. 18650 batteries). Cell and battery testing can detect early problems before the batteries are combined into a battery module for an EV or powerful tool. Battery packs in EV vehicles need to deliver extremely high-power levels (order of tens of kWatts), and batteries need to be tested/discharged at different power rates to mimic different modes of operation and power needs. They need to conform to all safety standards and must withstand rigorous safety testing.

“To address these new testing requirements, EV car manufacturers need high power electronic loads with arbitrary function capabilities to emulate and test their EV batteries under specific or arbitrary conditions.”

Brian Hsu, product marketing manager at AC Power Corp. (Preen): “There is a trend that fixed power supplies or programmable power supplies tried to apply GaN and Sic technology for making the power supplies in a compact size. Due to the new energy, energy storage, and electric vehicle industries growing, the DC testing voltage is getting higher and some of the test applications require bi-directional or regenerative type DC power supplies. And also for simulating the grid system, there is a trend in requiring larger programmable AC power supplies with the fault ride through testing features.”

Herman van Eijkelenburg, director of marketing at PPST Solutions: “Like the introduction of IGBTs in the 1980s, wide-band-gap power devices are fueling new levels of power density and power efficiency that will permeate over the next decade in a wide range of power conversion products. Current price points for these devices are not yet competitive for T&M applications, but we expect that to improve as the adoption of these technologies in higher volume applications increases. Another driver of innovation is the increased penetration of and increased performance of digital power stage controls, which allows higher levels of conversion efficiency and smaller package sizes for power sources and loads.”

Challenges

We’ve touched on a few different demands power supplies & loads vendors are facing in terms of meeting customer demands, but let’s go deeper. Here’s what our vendor respondents told us about the challenges their customers are facing, and how vendors are helping them conquer those challenges.Green and Lee, Tektronix: “Today’s design requirements call for higher dynamic range, and accuracy, at an effective cost of acquisition. Tektronix/Keithley instruments provide both conventional and specialized sources and loads. We have a 4-quadrant Source Measure Unit that can source 1000V and measure with 10pA sensitivity for leakage current and breakdown voltage testing.

“Minimizing output noise is an important challenge for testing low-power devices and sensitive circuits. Keithley offers low-noise linear-topology power supplies with power up to 375W for both low power and high-power circuits. We offer linear supplies up with up to 60V outputs, and we have a high precision power supply that can measure DUT sleep mode currents with 10nA resolution.

“For the portable, wireless device manufacturers, we offer a battery-simulating power supply that can emulate a model based on the battery’s discharge characteristics and the battery drain current drawn by the end product. By using a model for the battery, a designer can see how the end product performs over the life of the simulated battery. The designer can program the battery simulator for a specific output voltage or for a specific state-of-charge to see how the end product performs over a wide range of battery conditions. A designer no longer needs to discharge a battery or batteries to a specific state to test the end product. The battery simulator allows the designer to efficiently analyze the end product which saves significant development time.”

Schada, AMETEK: “Power supply customers will always want supplies that deliver higher performance at a lower cost. For vendors, that means designing supplies that can source more power with tighter tolerances. So that means balancing the use of new technologies that can deliver that higher performance while still maintaining a low cost per watt. Another significant challenge for customers is obtaining continuing technical support for their products as they get older. To address this need, we have recently introduced the AMECare Reliability Assurance Program, which is designed to provide ‘white glove’ support for our customers’ covered mission-critical power devices, with regular preventative maintenance, break-fix support, and legacy upgrades, beginning with a product’s purchase and extending through its entire life cycle.”

Hsu, AC Power Corp.: “Challenges include if power supply manufacturers can make large kVA power products with good enough experience in heat dissipation and cooling. Some applications may require certain modification on the power source based on the requirements. It will be very challenging for suppliers to produce a quality product and have it be cost-effective for manufacturing customers to apply in their production line, or burn-in and aging testing.”

Lee, Keysight: “Challenges may vary from one customer to another. The main features customers would like to have in a power supply to solve problems is provided below. The challenges for a power supply manufacturer consist of integrating all these different features into a single product, without compromising cost or performance.

- Form Factor, size, modularity, power density, multiple output channels

- Advanced measurement functions, capabilities, and analyzing features

- Built-in applications

- Sequencing and synchronizing multiple outputs

- Fast response time and transient behavior

- Integrated analysis; fast sampling rates, and data logging capabilities

- High programming and measurement accuracies

- Low input/output noise

- Arbitrary waveform generation; custom output waveform generation for both power supplies and loads

- Ability to produce more current through parallel or higher voltages with series connections

- Intuitive user interface and experience

- Digital input and output (I/O) control

- Safety: Protecting the user, device under test, and the equipment

- Documenting the test setups and measurements

- Ability for high energy loads to re-capture energy”

Rich Markley, value instruments product manager at Rohde & Schwarz: “Having the ability to test batteries is becoming a common need, both in terms of battery tests and power consumption tests (requiring a high dynamic range). We’ve recently introduced a new two-quadrant power supply focused on this exact need, with wide dynamic range, low noise, minimal ripple and excellent load recovery.”

Now on the market

Some of the new products/solutions that electronic test & measurement vendors have recently brought to market have already been mentioned above, but let’s recap what else has been introduced as of late.On the electronic load side, Kikusui has introduced a trio of offerings: the PLZ-5W series, the PLZ-5WZ series, and the PLZ-5WH series. The company says the PLZ-5W series has the market-leading slew rate—even at very low voltage—with high current for applications such as POL testing or any dynamic load testing. The PLZ-5WZ series is a model dedicated for battery impedance measurement. The load has the capability to have an AC current superimposed on its constant current to measure the impedance of the battery. The load can be operated through its dedicated application software and have the measurement. PLZ-5WH series is a high voltage model of 800V up to 100 kW.

In the second quarter of 2018, Tektronix introduced a new series of high power, triple output, linear power supplies. The company’s 2230G supplies provide up to 375W of power in a compact 2U high, half-rack wide enclosure. The 2230G-30-6 offers up to 6A from two channels; the 2230G-60-3 offers up to 60V from two channels. Adjustable, independent, and isolated channels can test two single voltage devices or a multiple voltage device with one power supply. Tektronix also introduced a compact 1U high, full rack wide, 4-channel two quadrant Source Measure Unit (model 2606) for high volume, space-saving manufacturing of low-power components and sub-assemblies. Tektronix’ 2450, 2460, 2461, and 2600-series SMUs all have built-in intelligence, which the company calls test script programming (TSP). A user can write test scripts to execute a test, customize the display, and control multiple tsp-enabled instruments and any LAN-based instrument. The TSP language uses a standard scripting language, Lua, that enables an instrument to be a master controller and execute a complete test.

AMETEK recently introduced the Asterion line of DC power supplies, which combined intelligence and flexibility to create an advanced platform of DC solutions in 1.7, 3.4, and 5.0 kW. Its features include: High power density in a 1U chassis up to 5kW; an intuitive touch panel control; availability in either fixed or autoranging output; multi-language display for global operation; auto paralleling for higher power; and full remote control via Virtual Panels. Additionally, AMETEK said its Sorensen SGX Series of high power programmable DC power supplies is “designed for exceptional load transient response, low noise, and the highest power density in the industry.” And finally, the company’s Shipboard Power Test Software Option is compliant with MIL-STD 1399 Section 300B of the Department of Defense Interface Standard for Electric Power, Alternating Current. This test option is available for use with five of AMETEK’s AC power source lines.

Adaptive Power Systems just launched a new series of high power DC power supplies that offer a 3:1 constant power mode, greatly reducing the number of models needed to cover output voltages from 30Vdc all the way up to 1500Vac. With a power density of 15kW in a 3U rack mount chassis and ability to parallel multiple units, these power supplies are well-suited for high power DC test applications on PV Inverters and Electric vehicle battery packs. Also new is the 6RL Series regenerative DC loads. These loads re-cycle energy back on the power grid rather than dissipating input power from the EUT into heat. This saves on both energy and HVAC costs compared to conventional dissipative electronic loads. Power density is 15kW in a 3U rack mount chassis and input voltage up to 1500Vdc.

AC Power Corp. recently released an ADG family of programmable DC power supplies that can reach 2000VDC or 25000A, making it suitable for new energy, EV industries, and energy storage-related DC testing. Preen also touts its AFV-P and AFV series of programmable AC power supplies, hailing it as the most cost-effective programmable AC power supply on the market.

About the Author