Subtle Magnetic Effect Leads to Bioelectronic Sensor Plus Energy Harvesting

What you’ll learn:

- What the magnetoelastic effect is and how it can be used.

- How an innovative design and fabrication technique led to a flexible magnetoelastic device.

- How this unique device can be used for both energy harvesting and sensing of biological parameters.

Engineers are aware of a wide range of physical effects ranging from well known (the piezoelectric effects) to somewhat less known (the skin effect) to far-less known (the Coanda effect), to cite just a few. These effects enable basic functions as well as sophisticated devices via subtle operating principles.

Now, a team at the UCLA Samueli School of Engineering has devised a novel soft and flexible self-powered bioelectronic device that’s also a sensor, based on a major twist (no pun intended) to the less known magnetoelastic effect. This effect is the change of a material's magnetic property under mechanical deformation (strain) and is the inverse of magnetostriction. Though observed since the 19th century, it’s normally associated with rigid materials.

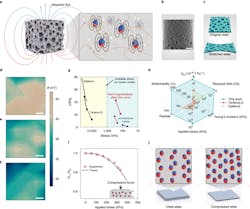

The researchers have shown, however, that the magnetoelastic effect can exist in a soft and flexible material, not just one that’s rigid. To prove their concept, the team used microscopic magnets dispersed in a paper-thin silicone matrix to generate a magnetic field that changes in strength as the matrix undulated. As the magnetic field’s strength shifts, electricity is generated and can be harvested, while the amount of current also can act as a sensor (Fig. 1).

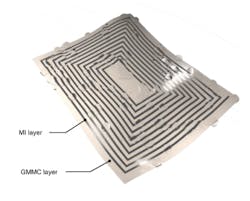

The team built a small, flexible magnetoelastic generator (MEG) about two centimeters square comprised of a platinum-catalyzed silicone polymer matrix (polydimethylsiloxane) and liquid metal coils of neodymium-iron-boron nanomagnets in a spiral-like arrangement as a magnetic induction layer (Fig. 2).

They attached it to a subject’s elbow with a soft, stretchy silicone band and observed a magnetoelastic effect. It was about four times greater than similarly sized arrangements that used rigid metal alloys while exploiting the same effect. Their device generated current of 4.27 mA/cm2, a value that they maintain is four orders of magnitude better than the closest comparable technology (Fig. 3).

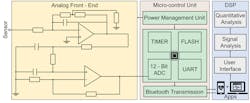

Using their complete sensor-to-smartphone system and algorithms, they were able to extract key cardiovascular parameters from the soft MEG in a sweaty condition (Fig. 4). This included factors such as pulse wave velocity and K value; upstroke time and stiffness index; and radial augmentation index and left ventricular ejection time.

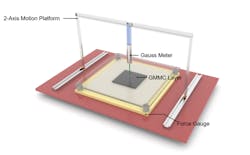

In addition to analyzing, devising, constructing, and evaluating their soft MEG, their work including extensive deep-physics analysis of magnetic-domain interaction at the atomic level. To assess magnetic flux under various strain conditions, they measured flux density in a GMMC (giant magnetomechanical coupling) fixture (Fig. 5).

Assistant professor of bioengineering and project leader Jun Chen noted that “what makes this technology unique is that it allows people to stretch and move with comfort when the device is pressed against human skin, and because it relies on magnetism rather than electricity, humidity and our own sweat do not compromise its effectiveness.”

Full details of the construction of the MEG and sensor and their combined performance as well as the underlying physics are in their paper “Giant magnetoelastic effect in soft systems for bioelectronics” published in Nature Material. There’s also a comprehensive 70-page Supplementary information posting plus two short videos, one on 3D tomography of the GMMC layer and the other on the smartphone-based wireless measurement of a human pulse in a real-world sweaty situation.

About the Author

Bill Schweber

Contributing Editor

Bill Schweber is an electronics engineer who has written three textbooks on electronic communications systems, as well as hundreds of technical articles, opinion columns, and product features. In past roles, he worked as a technical website manager for multiple topic-specific sites for EE Times, as well as both the Executive Editor and Analog Editor at EDN.

At Analog Devices Inc., Bill was in marketing communications (public relations). As a result, he has been on both sides of the technical PR function, presenting company products, stories, and messages to the media and also as the recipient of these.

Prior to the MarCom role at Analog, Bill was associate editor of their respected technical journal and worked in their product marketing and applications engineering groups. Before those roles, he was at Instron Corp., doing hands-on analog- and power-circuit design and systems integration for materials-testing machine controls.

Bill has an MSEE (Univ. of Mass) and BSEE (Columbia Univ.), is a Registered Professional Engineer, and holds an Advanced Class amateur radio license. He has also planned, written, and presented online courses on a variety of engineering topics, including MOSFET basics, ADC selection, and driving LEDs.