48-V Systems: What You Need to Know as Automakers Say Goodbye to 12 V

Members can download this article in PDF format.

What you’ll learn:

- Why automakers are finally migrating from 12- to 48-V automotive accessory power systems.

- An overview of the technical challenges automakers and their suppliers must overcome.

- An introduction to the architectural options and standards that govern 48-V automotive power systems.

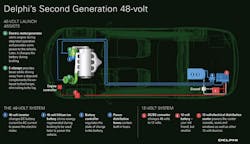

The 12-V automotive power system has dominated the industry for over 70 years, but it’s begun to cede that stranglehold to 48-V options. The higher-power versions offer numerous advantages, including the ability to deliver much higher levels of power across thinner, lighter, and lower-cost wiring harnesses. Such systems are also relatively inexpensive to implement because they don't need to meet the more stringent safety and performance requirements that govern so-called high-voltage systems rated for more than 62 V (Fig. 1).

Despite these long-term advantages, the short-term level of effort and investments it would take to re-tool vehicle designs, their manufacturing lines, and the supply chains that support them have delayed the widespread adoption of 48-V electrical systems in all but a handful of products.

Lately, though, the balance of this equation has begun to tip in favor of 48 V due to the growing adoption of power-hungry subsystems, such as active suspensions and electrical power steering, and mounting pressure on manufacturers to save weight and cost. Added incentives for the adoption of 48-V power systems are emerging from the greater numbers of electrical vehicles (EVs) in the market, which rely on electrical power for every aspect of their operation.

Fortunately, several architectures support the use of both 12- and 48-V systems in the same vehicle.1 They can make the transition easier by allowing for the use of existing "legacy" electronics wherever needed.

In this article, we'll explore some of the technical issues designers will face and need to overcome as they transition the next generations of trucks, cars, and other vehicles to 48-V systems.

A Slow Emergence

48-V vehicular power systems have been around for quite some time, mostly used to drive large pumps and actuators in off-road vehicles and other specialized applications. Over the past decade or so, they began to be used to reduce the currents required to drive electric superchargers, active suspension systems, and other power-hungry functions in passenger cars and work vehicles.

More recently, increased regulatory pressure to improve fuel economy has strengthened manufacturers' interest in using 48 V to reduce direct loads on their vehicles' internal combustion engines. This has been accomplished by electrifying other high-power accessory functions, such as power steering, air conditioning, and coolant pumps.

At least in theory, migration to a 48-V accessory bus also provided an economical way to produce transitional products in the form of so-called “mild hybrid.” Mild hybrids augment a relatively small conventional engine with a 48-V motor-generator that can be used to provide additional torque during acceleration and regenerative braking, as well as support auto stop/start functionality when the vehicle is coasting or stopped at a light.

A mild-hybrid system’s relatively low levels of assist deliver only offer a fraction of the efficiency improvements offered by a full hybrid drive system. However, they can be easily incorporated into an existing ICE vehicle design and typically add less than $1K to their production cost (Fig. 2).

While mild hybrids helped expand the demand for 48-V components, it's expected that they will find even greater use in the upcoming generation of EVs where electricity must be used to drive all accessory functions. This includes power steering and brakes, active suspension, coolant pumps, and air-conditioning compressors, any one of which may draw peak loads of multiple kilowatts.

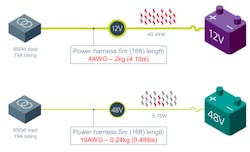

Switching to a 48-V electrical system greatly reduces the current levels the vehicle's wiring harness needs to supply to its high-power subsystems, thereby enabling the use of lighter, smaller-gauge wires that cost considerably less per foot. For example, delivering 950 W of 12-V power (79 A) across a 12-ft. wiring harness requires a 4 AWG cable that weighs roughly 2 kg (4.1 lbs.). In contrast, powering the same 950-W load with 48 V can be accomplished using 10 AWG wire, which weighs 0.24 kg (>0.5 lb.), resulting in an 85% savings in weight (Fig. 3).

In addition to the weight and cost savings, switching to a 48-V power system can dramatically reduce resistive losses that could directly impact an EV's range. Using the previous example, we find that switching to the higher voltage (and lower current) drops the harnesses' resistive losses from 40 W to only 5.8 W. When multiplied by the number of high-power subsystems used in a typical EV, the potential savings can shave the vehicle's weight by 100-150 lbs. and eliminate enough resistive losses to contribute roughly 10 km to its range.

A Gradual Transition to 48 V

So far, Tesla seems to be the only manufacturer to have fully embraced 48-V power, beginning with its upcoming CyberTruck, followed by design changes that will eliminate the 12-V bus from several of their existing models. On top of enjoying the previously mentioned advantages, it's reported that Tesla has already created its own “secret” accessories team dedicated to developing products specifically for the 48-V architecture, such as lighting, winches, and air compressors.2

Most other automakers, though, will have to distribute the enormous costs of overhauling their designs, manufacturing lines, and supply chains over a much longer period.

During the expected 10- to 15-year period transition to 48-V power, many vehicles will continue to use existing 12-V accessories and subsystems that work well and would be too costly to re-engineer immediately. This can be accomplished by running a legacy 12-V harness throughout the vehicle.

However, the more practical method is to implement a distributed power-delivery architecture, such as the one developed by Vicor (Fig. 4). In a distributed system, the vehicle's 48 V is derived from the vehicle's primary 400/800-V battery and then sent to 12-V power converters located close to the load points. Redundant power for braking, steering, and other ASIL D safety-critical functions can be derived by feeding them with two or more independent, isolated voltage converters.3

Transitioning to a 48-V power architecture also raises the question about where the 48 V will come from. In the case of Tesla, the company has chosen to power the 48-V bus via a small standalone lithium-ion auxiliary battery that’s charged from the vehicle's main battery pack.

Alternatively, some manufacturers may choose to eliminate the need for a separate 48-V battery by creating a "virtual" battery consisting of a low-impedance converter, regulator, and small storage devices, such as supercapacitors. This would provide hold-up power for the door lock and other systems that must remain active while the main battery is disconnected.

Getting Started

The details of a particular manufacturer's transition to 48 V will vary greatly depending on their products, their technical maturity, and the requirements of the customers they serve. But nearly anyone beginning the journey can benefit from a solid grounding in the basic standards and design practices related to the technologies they will be using. This includes:

- ISO 217804 covers requirements and tests for the electric and electronic components in road vehicles equipped with an electrical system operating at a nominal voltage of 48 V dc. This includes general requirements on 48-V dc electrical systems, voltage ranges, and slow voltage transients and fluctuations (not including EMC).

- The VDA Recommendation 3205 is published and maintained by the ZVEI-German Electrical and Electronic Manufacturers’ Association. It covers a wide range of specifications and test requirements for electric and electronic components in motor vehicles for the development of a 48-V power supply. ZVEI's document "48-Volt Electrical Systems – A Key Technology Paving to the Road to Electric Mobility"6 provides practical insights about the requirements posed by VDA 320 and their fulfillment.

References

1. Automotive 400-V battery to 12-V, 3.6-kW DC/DC converter reference design, Texas Instruments.

2. “Why Tesla’s move to 48-volt electrical architecture is an industry game changer,” Tim James, The Driven, March 20, 2023.

3. ASIL D safety concept-assessed high-speed traction, bi-directional DC/DC conversion reference design, Texas Instruments.

4. “ISO 21780:2020 - Road vehicles — Supply voltage of 48 V — Electrical requirements and tests,” International Standards Organization, 2020.

5. “VDA 320: Electric and Electronic Components in Motor Vehicles 48 V On-Board Power Supply Requirements and Tests,” German Electrical and Electronic Manufacturers’ Association, 2016.

6. “48-Volt Electrical Systems: A Key Technology Paving to the Road to Electric Mobility,” German Electrical and Electronic Manufacturers’ Association, 2016.

About the Author

Lee Goldberg

Contributing Editor

Lee Goldberg is a self-identified “Recovering Engineer,” Maker/Hacker, Green-Tech Maven, Aviator, Gadfly, and Geek Dad. He spent the first 18 years of his career helping design microprocessors, embedded systems, renewable energy applications, and the occasional interplanetary spacecraft. After trading his ‘scope and soldering iron for a keyboard and a second career as a tech journalist, he’s spent the next two decades at several print and online engineering publications.

Lee’s current focus is power electronics, especially the technologies involved with energy efficiency, energy management, and renewable energy. This dovetails with his coverage of sustainable technologies and various environmental and social issues within the engineering community that he began in 1996. Lee also covers 3D printers, open-source hardware, and other Maker/Hacker technologies.

Lee holds a BSEE in Electrical Engineering from Thomas Edison College, and participated in a colloquium on technology, society, and the environment at Goddard College’s Institute for Social Ecology. His book, “Green Electronics/Green Bottom Line - A Commonsense Guide To Environmentally Responsible Engineering and Management,” was published by Newnes Press.

Lee, his wife Catherine, and his daughter Anwyn currently reside in the outskirts of Princeton N.J., where they masquerade as a typical suburban family.

Lee also writes the regular PowerBites series.