Initial Results from Electronic Design’s Maker Survey

What you’ll learn:

- What are makers interested in?

- What types of tools are makers using?

- What are makers recommending for new makers?

Presented here are the latest results of our ongoing Maker Survey. Take it if you haven’t already done so. We will be following up with more coverage in the future. I did a quick snapshot of the results so we could get this article into our upcoming Sept/Oct issue of Electronic Design.

What Tools are Makers Using?

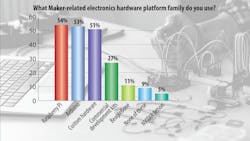

Not surprisingly, Raspberry Pi and Arduino are the two most popular development platforms for makers, followed by customized hardware and other commercial platforms (Fig. 1). The latter often provide Raspberry Pi and Arduino headers so that developers have access to the plethora of expansion options available in the respective ecosystems.

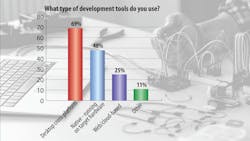

We did ask a few questions about the tools that developers are using. Of course, 3D printers showed up in the list, along with the modules and boards already mentioned. We also asked where they built their software. Desktops remain the platform of choice for development, although a significant number use web-based tools, which have become more prevalent (Fig. 2).

Going the web-based tool route has a number of advantages, but it also brings about challenges ranging from connecting to a target device to providing debugging support. Likewise, some platforms are only available with web-based tools, while in other cases there’s a desktop or native tool that may differ in functionality or interface because of web-based limitations.

Recommendations from Makers to Makers

We also included some open-ended questions in the survey. One was about (short) recommendations from pros to novices. What follows are some insights that should be useful.

“Be brave enough to fail at something new.” – StevenS

“Start small, you'll get there!” – KeriS

“Always try new things. The more you learn the better you will be. Don't be afraid of things not working at first, it's part of Making.” – JerryP

“Reach out to distributors, they have the knowledge and bandwidth to support where OEMs won't, or won’t care because your sale number will be too small. Be open minded and talk about your project. Too many people love NDAs. Stop with this! It’s throwing your money at lawyers.” – GerryK

“Buy a 3D printer—they're cheap and absolutely the ULTIMATE toy. Then concentrate on learning the BASICS of electronics, programming, and mechanics.” – DylanR

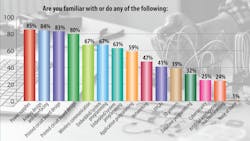

What Makers Know Already

Our survey was already skewed, as the target survey audience is primarily Electronic Design readers. This led to results that highlighted the fact that our readers have a good understanding of many of the technologies that makers need to employ in most electronic-related projects (Fig. 3).

We were glad to see that websites like Electronic Design were popular sources of information for developers (Fig. 4). Of course, YouTube is up there. Watching step-by-step project videos or webinars that walk through technologies or tools is a great way to learn about new topics.

Don’t forget to check our selection of videos on YouTube, including our Kit Close-Up series as well as the Electronic Design YouTube channel. You can find all of those videos on the Electronic Design website, but the difference is that we pair the videos with an article and resources that makers will find useful.

Turning Maker Projects into Products

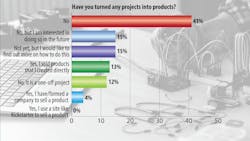

Most maker projects are for one-off projects and to learn about a technology (Fig. 5). This was to be expected, as most makers start out wanting to learn about topics they’re not well-versed in yet.

What I did find surprising is the percentage who have turned, or are interested in turning, their projects into products. This is not an easy task. It requires additional expertise over and above what it takes to make a prototype. A prototype is just to show that something is practical.

Turning a project into a product is a much more involved process, one that adds extra technical chores including source of materials, design for manufacturing, and design for testing. It’s not simply a matter of putting chips on a printed circuit board (PCB) and dropping it into a box to be shipped out.

More Maker Results to Come

I plan on following this article up with a more detailed examination of every question, as more of you have a chance to take the survey.

About the Author

William G. Wong

Senior Content Director - Electronic Design and Microwaves & RF

I am Editor of Electronic Design focusing on embedded, software, and systems. As Senior Content Director, I also manage Microwaves & RF and I work with a great team of editors to provide engineers, programmers, developers and technical managers with interesting and useful articles and videos on a regular basis. Check out our free newsletters to see the latest content.

You can send press releases for new products for possible coverage on the website. I am also interested in receiving contributed articles for publishing on our website. Use our template and send to me along with a signed release form.

Check out my blog, AltEmbedded on Electronic Design, as well as his latest articles on this site that are listed below.

You can visit my social media via these links:

- AltEmbedded on Electronic Design

- Bill Wong on Facebook

- @AltEmbedded on Twitter

- Bill Wong on LinkedIn

I earned a Bachelor of Electrical Engineering at the Georgia Institute of Technology and a Masters in Computer Science from Rutgers University. I still do a bit of programming using everything from C and C++ to Rust and Ada/SPARK. I do a bit of PHP programming for Drupal websites. I have posted a few Drupal modules.

I still get a hand on software and electronic hardware. Some of this can be found on our Kit Close-Up video series. You can also see me on many of our TechXchange Talk videos. I am interested in a range of projects from robotics to artificial intelligence.