How does the static-discharge enemy look to someone who spends eight hours a day on the front lines of the battle at the workstation? Is the first line of defense—the army of electrical assemblers—suitably armed and motivated?

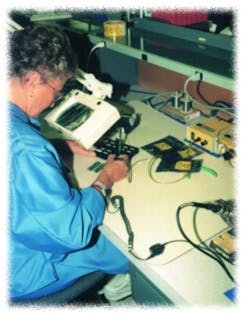

Joan Stabenow, an electrical assembler now at Invensys and previously at Sund-strand and Loral, all in Sarasota, FL, has been on that ESD battlefront for 20 years. She has some answers for us.

Ms. Stabenow first heard of the static-control problem and its implications in 1979 while working at Loral. “My first reaction was very negative,” she recalled. “I was sure that this was just another exercise and that everything would be back to normal in a few days. After all, at that time I had been assembling electronic equipment for 15 years, and no one had complained before. But I figured I could tolerate a silly new rule if that’s what it took to keep my supervisor happy.”

Quite frankly, probably the supervisor was a bit skeptical, too. No one had explained ESD to any of the production people.

Ms. Stabenow’s first ESD control device was a wrist strap. “I felt like a dog on a leash and could think of no good reason to have that wire holding me near the workstation. It gave me the same restricted feeling as my car seatbelt. Fortunately, both the wrist strap and the seatbelt became a way of life after a while.

“I have learned to keep the strap on my wrist when I leave my workstation during the day,” she continued. “I also found that the strap doesn’t make good contact some days until I use a static-dissipative hand cream on my wrist.”

Ms. Stabenow has worn ESD-control gloves and finger cots without problems. Smocks are another story. “This is my biggest ESD gripe,” she said. “I detest the need to snap it from top to bottom on warm, humid days. I wonder if the smock requirement is an overkill.”

ESD-protected storage is big on Ms. Stabenow’s priority list. She doesn’t want her products to be destroyed by the carelessness of a material handler unfamiliar with this invisible threat. “Whenever I leave the workstation, I place sensitive components and assemblies in black antistatic totes and seal them. When someone delivers or picks up parts at my station, I watch carefully to assure myself that the transit procedure is ESD safe.”

The computer terminal at Ms. Stabenow’s workstation is on an antistatic mat. An ionizer on the bench helps control the possible static buildup on her tools and other equipment. Since the action of the ionizer is invisible, she has to accept the assurances that it is helping in the ESD control process at face value.

Visitors to the work area are Ms. Stabenow’s biggest challenge. It is necessary for the cleaning crew, customers, and even the plant manager to visit her workstation from time to time—but they mustn’t undo all the hard work Ms. Stabenow has done to keep the sparks under control.

So what does Ms. Stabenow do? She guards her components and workplace with a vengeance. The idea of giving visitors different-colored smocks sounds good to her because it gives an assembler an easy way to spot them.

Helping Others Fight the Battle

Because Ms. Stabenow is an old-timer in ESD control and a natural leader, she has informally helped to educate dozens of others on the subject. There are many short courses, typically two hours or less, on ESD control. But new employees understand ESD better when they hear about it from someone who has been around a while and fully believes in the program.

“The most convincing motivator to learn about ESD is product quality,” Ms. Stabenow said. “No one wants to have the results of their labor lost because of a defect in the assembly process.”

Auditing has been a standard part of the ESD-control regimen for each of Ms. Stabenow’s employers. She checks in, verifies that her wrist strap works properly, and initials a form. From time to time, with no advance notice, a company auditor verifies that every assembler has signed the list.

Several other ESD control checks at the workstation are part of the audit routine. The assembly team prides itself when it passes each check or works harder when a violation is discovered.

Has this veteran assembler ever seen a dramatic example to back up the stories about the seriousness of the ESD threat? “You bet. Several years ago, I blew some PROMs. A few days later, I learned that several of the PROMs were defective and that the cause likely was ESD,” Ms. Stabenow explained. “Were they damaged by handling or storage before I got them, or did I damage them at my station by improper ESD control practices? Was the damage caused after they left my station?”

To this day, Ms. Stabenow doesn’t know the answer. But she does know the quality of valuable products was jeopardized by someone or something in the manufacturing sequence.

One of the frightening things to come from the PROM experience is the realization that latent defects can go to the customer undetected. Good components look the same as those damaged by ESD, and latent damage may not even show up in test.

Ms. Stabenow shudders when she thinks that some of her products are going into vehicles where failures could cost lives. “When I put an electrolytic capacitor in backward, there is black smoke and the electrolyte is sprayed all over the board. I wish the results of a static discharge were as visible, but I know that isn’t possible.”

Ms. Stabenow offered some advice to ESD control engineers: “Remember that ESD control is not about a set of rules at the workstation. It is about a partnership between engineers, assemblers, material handlers, and management for the overall good of the company and service to the customer.

“We electrical assemblers are eager to be part of the solution, not just employees who go to those classes and blindly do what we are told. And we will be more motivated if we are given specific examples of ESD problems in our plant, hopefully with visual aids, and then invited to be part of the decision-making tea.”

March 2000