Making an informed choice between inline and offline device programming requires an in-depth look at both tangible and intangible manufacturing costs.

Electronic products such as cell phones, DVD recorders, PDAs, and automotive infotainment systems require an enormous amount of user memory compared to a decade ago. The merging of multiple functions�camera, video, MP3, PDA, and cell phone�into a single product has accelerated this trend. The large memories installed for a combination of user data, pictures, music, and video games have serious implications for device programming.

More than ever, manufacturers face critical strategic decisions on device-programming issues with important business-management ramifications. Low-volume device programming, such as that used for prototyping and new product introductions, may follow a different programming strategy than that used for products in high-volume production.

Selecting a Strategy

Choosing between automated inline and offline programming strategies involves several criteria. Those that most influence the CPP device are the following.

Supply-Chain Management

The supply-chain management has been the subject of countless articles that discuss lean manufacturing principles as the most effective path to improved operating efficiency. Many production managers interpret this as a strategy of reducing on-hand inventories to hours, as opposed to days or weeks, and not handling inventory more than once.

For programmable devices, effective supply-chain management requires a good sense of how frequently firmware changes in an end product. One of the primary benefits of programmable device technologies is the ease of making engineering changes to products in manufacturing.

However, managers should be aware of the potential impact of work-in-progress (WIP) logistics on the bottom line. In particular, they need to consider the logistics of inventory handling during the reprogramming process triggered by an engineering change.

Programming System Flexibility

Programming system flexibility should take into account manufacturing requirements in the way blank devices are received and how they are identified and tracked through all production steps. For example, blank devices may be delivered in any of several component carrier media. These could be of standard design or unique to a specific semiconductor vendor.

Operational Logistics

Unless programming is outsourced, the unit programming cost is among the less visible programming variables. Computing the CPP device should include the depreciated capital cost of the programming equipment, the equipment programming output, programming consumable costs, operator costs, device failures, and consequential reprogramming costs. Many manufacturers prefer to outsource device programming rather than manage that process internally.

Device Volume and Product Mix

Device-volume and product-mix issues involve the quantity of each device that is to be programmed and the number of different device designs produced by the manufacturer. Changes to the programming system include downloading different algorithms and changing the socket-adapter modules that are unique to each programmable device.

Batch Volumes

Companies that produce cell phones often are considered high-volume/low-mix manufacturers. They program from hundreds of thousands to millions of memory devices each year, all of the same type and package configuration. Since the volume is high and the number of different devices low, only infrequent changeovers are required.

Lower volume producers often are characterized as high-mix manufacturers. High mix means the average programming job may only consume several hundred to a few thousand devices before a changeover to the next product run takes place. The challenge is knowing the economics of the volume-mix curve as well as the predictability of the next programming task.

Offline Programming Strategies

Offline programming is defined as the process of transferring the device data pattern or firmware from the source file via a programmer to the blank device, independent of the end-product manufacturing line. Offline programming systems typically are stand-alone systems that program, mark, and repackage the programmed devices. The marking system typically identifies devices by means of a laser, dot marking, or labeling. Repackaging the devices places them in a media suitable for storage or the printed circuit board (PCB) assembly process.

Critical to the offline programming strategy is application suitability. Offline programming is used more often for a wide range of device types and packages, independent of programming volumes.

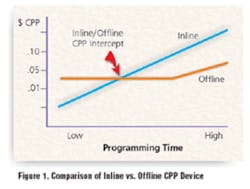

When device-programming times exceed the component handler pick-and-place times, as is the case for complex memories, high-volume offline automated systems with a large number of programming sites are the most cost-effective (assuming a system where machine robotics are continuous). When device programming times do not exceed the handler takt time (see sidebar), fewer programming sites are needed to maintain high system throughput, and the CPP device is relatively low (Figure 1).

Due to the initial cost of investment for offline processes, the cost-per-part plot remains flat until the programming time exceeds the throughput of the placement system (knee of offline curve).

Programming centers, original design manufacturers (ODMs), and electronic manufacturing services (EMS) are typical users of offline systems due to the uncertainty of programming tasks and the need for system flexibility. These types of companies also are driven to automated systems by their original equipment manufacturer (OEM) customers, who increasingly demand the highest quality preprogrammed devices to reduce end-product scrap and warranty replacement costs. Furthermore, programming-equipment capital costs have declined in recent years, making automated programmers more economical than manual tools, even for small lots.

Product or device changeover is an obvious cost but also the one most often ignored. This is especially true when the programmer equipment is not being used as efficiently as it should be due to complexity or unreliable operation.

Inefficiencies also can occur due to increased job processing times that arise from the extended downloading of new device firmware. In addition, media changeovers reduce the production time of automated equipment, sometimes delaying jobs by hours if not days.

Production operations that have their own offline systems find that when a machine operation has a complex setup and is difficult to use, then the operator skill level can be a critical and high-cost variable. An automated programming system that is easy and intuitive to set up with simple instructions not only makes creating jobs efficient, but also reduces fatigue, lowers operator costs, and improves machine utilization time.

Inline Programming Strategies

Inline programming is the process described as programming at the point of device placement in a PCB assembly line. This involves integrating the programmer into the SMT assembly equipment. Each blank device is programmed and delivered directly to the SMT pick-and-place head. This means that blank devices are programmed immediately prior to PCB assembly.

Inline systems commonly are used by EMS, ODM, and OEM companies that understand the techniques and benefits of lean manufacturing. More importantly, these techniques are tightly integrated into their manufacturing operations to help them remain competitive.

An effective inline programming strategy is centered on takt time. Devices that have low memory storage or shorter programming times or require the use of multiple inline systems often influence the economics of this approach. The benefits of programming immediately prior to circuit placement are process scalability, reduced inventories, higher programmed part quality, reduced programming cost per device, lower operator costs, and faster code changes.

Higher volume end-product manufacturing often is associated with takt times as low as 30 to 35 seconds for multipaneled PCBs being assembled on an SMT line. As with other inline feeders in the system, such as standard tape feeders, inline programmers are scalable. This gives a manufacturer the capability to increase throughput by simply adding additional programmer units.

Inventories of multilevel software products are a huge burden on a manufacturing operation. The measure of a successful inline programming implementation is the number of preprogrammed devices in inventory compared to the number of blank devices.

Because inline programming uses only blank devices, it is not necessary to inventory preprogrammed devices. Additionally, the ratio of part numbers is dramatically reduced to one�the blank device.

With any complex SMT device, there is no method of assuring contact coplanarity of the leads or ball grid array and silicon integrity prior to placement on the PCB. However, during inline programming, each device is functionally tested so every part presented to the placement equipment is good.

Functional testing occurs during inline programming because device contacts must be present and in the right location, which effectively tests for coplanarity. If a device fails to program, this will indicate bad silicon. Any device that fails a programmer in-socket test is rejected for inspection prior to the SMT placement process.

Manufacturers using inline systems enjoy lower manufacturing cost per device because of the reduction in operator expenses and lower cost of capital per assembly line compared to equivalent offline systems subjected to the same volume/mix characteristics. Still, these economies can be easily compromised by the firmware changeover process.

Manufacturers must ensure that the right code is introduced at the right time for each batch, otherwise rework frequency increases because of the need to reprogram. Together, programmer in-socket testing and tight control of firmware changes reduce the number of boards scrapped at the functional test station and the probability of assembly-related failures once the product has reached the consumer.

Operator intervention and the opportunity for operator error also are important considerations for inline programming. Manufacturing managers need to understand the effect of operator involvement on the assembly line when defining the programming strategy.

Financial Implications

Many electronic manufacturing companies use a conversion cost metric to measure their cost of operations associated with SMT equipment. This metric is based on the cost of the SMT equipment and expressed as the cost of converting individual product components into a finished assembly.

One of the larger cost-related issues in device programming is the price of consumables, notably socket adapters. The programming volume drives the rate of consumption and the total cost of these mechanical adapters. Various socket types are available for different device packages, and each one is rated for a different number of device insertions.

Adapters for finer pitched arrays tend to cost more than those with wider spacing. A growing number of devices today are in the form of fine-pitch arrays of leaded and nonleaded SM packages such as quad flat pack, and ball grid array.

In addition to standard burn-in socket adapters, high insertion count (HIC) adapters are becoming more popular for mainstream device packages. While they have a higher acquisition cost than other adapters, HIC socket adapters can reduce the programming consumable cost to as low as a fraction of a penny. More surprising are the results of recent studies showing that the higher acquisition costs of HICs can be paid back with programming volumes of less than 100,000 devices.

Nevertheless, reducing consumable costs can have a significant impact on CPP device, and this can be affected by programmer design. For example, Data I/O�s connected programming strategy uses a common programmer architecture for both offline and inline programmer systems. This further decreases the costs of consumables and switching between processes.

Inventory and logistical costs can be a heavy burden on any manufacturing organization. The key for managers is to recognize and control these expenses. When products have increasing levels of functionality and many firmware variations, keeping inventory becomes a logistical nightmare.

With offline programming, whether via external outsourcing or an internal program center, a firmware change can make many weeks of inventory instantly obsolete. The only solution is to retrieve devices from inventory and reprogram them with updated code. Unfortunately, retrieving and reprogramming devices are common occurrences with a huge impact that falls directly to the bottom line as a manufacturing expense.

Defining an automated-device programming strategy is a complex task that should encompass both tangible and intangible costs over the entire manufacturing process. Given a manufacturer�s unique requirements, one strategy may be more advantageous than the other. Or it may be that the most effective strategy involves a combination of offline and inline programmers.

About the Author

Mark Briant is the senior product manager for automated products at Data I/O. He has spent considerable time in the SMT industry, previously serving as a product manager at SMT Feeder Products and at DEK Printing Machines. Data I/O, 10525 Willows Rd. N.E., Redmond, WA 98073-9746, 425-881-6444, e-mail: [email protected]

September 2004