Digital power means more than printing a 1 and 0 next to the on/off switch.

The fact that power supply companies disagree about what the term digital power means is a sure sign of the technology�s infancy. Digital control techniques are expected to benefit power supplies just as digital motor-drive controllers have improved performance and reduced cost compared to their traditional analog counterparts.

A basic closed-loop regulated supply can be implemented either digitally or with analog circuitry, but until recently the higher cost of a digital solution made it unattractive. On the other hand, analog control loops soon become very complicated if more than a straightforward feedback scheme is implemented. Analog power supply ICs tend to have low levels of integration so many devices are required. And, most analog power supplies are very limited in the depth of auxiliary monitoring and adaptive features they provide.

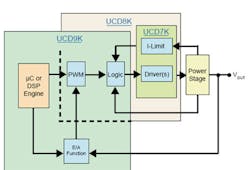

The increasing sophistication and improved price/performance ratio of digital power control technology are evident in successive Texas Instruments� (TI) Fusion Digital Power� Devices (Figure 1). The UCD7K family integrates high-current MOSFET gate drivers, programmable analog over-current detection, and a 3.3-V linear regulator for auxiliary circuitry. This device is driven by a separate pulse width modulation (PWM) digital power controller and control logic including a microprocessor or digital signal processor (DSP).

Moving up to the UCD8K devices, PWM circuits and output drivers have been added to the basic UCD7K features. Because the UCD8K IC closes the control loop in an analog manner, this device requires only external digital supervisor functions consisting of clock generation, housekeeping, and communications. The IC offers both voltage-mode and peak current-mode control. The operating frequency and maximum duty cycle are set by the input clock signal from the digital supervisor.

In the UCD9K family, a 12-b, 16-channel ADC operating at up to a 12.5-MHz rate provides the signals necessary for digital closed-loop control. You can think of the UCD9K devices as DSPs customized for digital power control. The ICs contain all the required DSP functionality together with the PWM, conversion, and communications circuits.

Four major factors that characterize digital supplies based on this family of devices were listed in a recent TI presentation: programmability, awareness relating to monitoring capabilities, responsiveness, and digital loop control. Of these, digital loop control generally is the characteristic most recently implied by the term digital power.1

Performance Beyond Analog

According to Bob Zollo, Agilent Technologies� power supply product manager, �Agilent interprets digital power as the control of the delivery of power using digital means. That definition includes all aspects of digital control. For example, voltage and current levels are programmable. Also, we use digital control to protect the end customer�s load through digital-based monitoring of key facets of the power supply.

�And, in our latest products, we also use digital control in the most complex way, which includes digital regulation of the output voltage and current through both linear and nonlinear feedback systems. Finally, digital control is used for power management for redundancy and budgeting in limited power environments,� he explained.

Digitally implemented functions typically included under monitoring and protection headings were discussed in a TI paper presented at the 2004 Digital Power Forum: �Design Review of �-Brick Digitally Assisted Power Supply� by Brian Shaffer. The term digitally assisted refers to the UCD8K device upon which this design is based.

Output voltage is controlled by analog PWM within limits set digitally. The clock signal input to the UCD8K sets the switching repetition rate. During soft start, the clock pulse width is increased gradually to its maximum. This pulse width corresponds to the maximum volt-second (VS) product allowed and prevents transformer core saturation by input transients. When the supply is running normally, the analog control loop will produce PWM pulses shorter than the maximum VS clamp value.

Because the VS clamp signal is generated digitally, it can be more flexible than a directly derived analog signal. For example, the VS product can be a higher value for a programmed number of switching cycles. Similarly, should an extended number of transients be detected, the VS product can be lowered. The capabilities afforded by digital technology support a VS clamp design that doesn�t degrade power supply performance under transient input conditions. Neither is a wasteful over-design margin required.

Similarly, the peak drain-source voltage (VDS) across the switching device need not be a constant. It can be higher for a pre-set number of switching cycles and reduced should an extended number of transients be present. Over-current detection also can apply more complex criteria, resulting in improved performance. For example, a higher output current could be supported for a number of switching cycles to provide faster load transient response. Or, output current could be controlled to implement a constant output power function.

Quantities monitored or controlled may include the input voltage low- and high-level limits, the average input current, the switching device maximum VDS and temperature, the maximum switching duty cycle, the soft start time delay, current limit parameters, and device temperature warning limits. Because all these values are in digital form, system monitoring, configuration, adjustments, and test and calibration via an integrated communications bus are straightforward.

Elgar Electronics Corp. (EEC) also designs and manufactures digital power supplies. Peter Allen, the company�s ReFlex Power product manager, said, �Satisfying the broad set of performance requirements represented by diverse applications is a significant challenge. With traditional analog control loops, there are hardware design trade-offs that have to be made for each model within a product family to balance transient response, slew rate, stability, noise and ripple, and regulation.

�The ReFlex Power supplies replace the hardware-defined transfer functions of traditional outer feedback control loops and protective supervisory loops with firmware-defined, high-speed FPGA-based equivalents. As an example of the performance achieved through this approach,� he continued, �the digital control in the programmable DC supplies provides 0.1% voltage programming accuracy and 0.01% load regulation for a 100% load step change.�

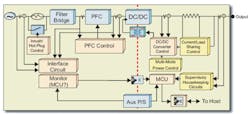

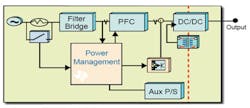

Figures 2a and 2b compare the complexity of a traditional analog power supply to that of a digitally controlled power supply. The digital power management block in Figure 2b includes a multichannel ADC to digitize both output and supervisory signals, logic to implement closed-loop control algorithms, monitoring circuitry, a digital communications interface, and a power factor correction controller among other functions. The digital supply�s operating characteristics are determined by programmed values stored in nonvolatile memory.

Benefits Beyond Analog

Additional related topics addressed in the paper presented by TI�s Mr. Shaffer include efficiency optimization achieved by turning off parallel power supplies so the ones remaining active operate at their highest efficiency. The operating frequency could be dithered to reduce the interference at a specific frequency. Under light load conditions, a burst mode of operation could minimize power consumption. And, if monitored values severely exceeded limits, module failure could be anticipated. The feasibility of these and similar additional capabilities follows from the use of digital control technology.

Closed-case calibration, repeatable measurements, and a programmable output step profile are among the benefits digital control has brought to AMREL�s line of analog power supplies. A variety of interfaces including RS-485, RS-232, GPIB, Ethernet, and USB enables remote operation as well as parallel connections with load sharing. Programmability also provides capabilities such as synchronized triggering in master-slave configurations and a programmable power-on sequence.

For California Instruments, digital power has a special meaning. This company designs and manufactures AC power sources that take full advantage of DSP technology. Besides acquiring and processing data within the supply, a DSP affords the opportunity to provide additional functionality.

|

FOR MORE INFORMATION |

| Agilent Technologies | N6700 Modular Power System | www.rsleads.com/608ee-179 |

| American Reliance | SPSE Series With Embedded Ethernet | www.rsleads.com/608ee-180 |

| California Instruments | Compact i/iX | www.rsleads.com/608ee-181 |

| Elgar Electronics | ReFlex Power Supplies (requires registration) | www.rsleads.com/608ee-182 |

| Keithley Instruments | 2300 Series Fast Transient Response Power Supplies | www.rsleads.com/608ee-183 |

| Texas Instruments | Fusion Digital Power Devices | www.rsleads.com/608ee-184 |

The company�s marketing manager, Brian Dillard, explained, �In the case of an AC power source, the capability to measure distortion, perform FFTs, and create user-defined waveforms adds greatly to the product�s versatility. In addition, functions such as programmable output impedance and enhanced load regulation modes become possible for both AC and DC supplies.

�Most of California Instruments� power supplies use DSP-based controllers running real-time operating systems to process control and measurement tasks. As the cost of ADC and DAC devices continues to decrease,� he postulated, �the use of digital domain processing will only increase. Also, faster conversion speeds will allow these approaches to take over some of the traditional analog functions while adding new capabilities through dynamically alterable algorithms. In addition, the ability to download firmware updates allows customers to add new test capabilities as time progresses, extending the useful life of the product.�

The enhanced system-wide control opportunities afforded by digital technology were highlighted by Agilent�s Mr. Zollo. �In the N6700 Modular Power System, we offer digital power management, which allows a 400-W mainframe to be populated with up to 1,200 W of power supplies. The system allocates power to the supplies with local digital monitoring and control of the maximum power of each. Also, digital feedback in the over-voltage and over-current protection systems makes protection faster and more accurate than analog methods would have allowed while reducing parts count and simplifying development.�

EEC has made extensive use of high-speed access to key power supply parameters. As Mr. Allen explained, �Digital control technology permits dynamic and adaptive optimization of the power supply parameters to suit customer applications. The adaptive control of loop parameters supports simultaneous optimization of programming accuracy, regulation, and dynamic response. In addition, complex control algorithms such as power-mode control or variable slew-rate control are enabled by this technology.

�Advantages of digital power supplies extend especially to owners of legacy ATE systems. An obsolete supply can be replaced by a digital supply programmed to replicate the old supply�s operating characteristics including output response,� he continued. �Greater flexibility and economy also result from digital control that enables power supply components to be combined in series or parallel configurations to create virtual power supplies. Fewer assets are required to support more test regimens.�

To Keithley Instruments, a digital power supply is digitally controlled and includes digital communications and accurate measurement capabilities. Andy Armutat, the company�s precision electronics market development manager, explained that Keithley specializes in high integrity sourcing and measurement capabilities: �Traditional power supplies are not known for high integrity measurements. In contrast, Keithley digital power supplies merge the company�s source and measurement technologies to collect critical data not available with conventional supplies.

�For example, the 2300 Series Supplies address applications requiring battery simulation, pulsed load current measurements, programmable bandwidth and output impedance, and precision current measurement. In general,� he continued, �Keithley SourceMeter instruments provide four-quadrant operation with precision voltage or current sourcing, built-in pulse and sweep modes, true current source capability, and measurements with 1-�V and 1-pA resolutions.�

In addition, more advanced digital features may be added to address specific applications. For example, development and production line testing of battery-powered portable devices require special power supply features to accurately measure load profiles and ultralow quiescent power draw. These needs led Keithley to develop specialized source-measure capabilities.

Claimed and Disputed Benefits

EEC�s Mr. Allen listed a number of advantages afforded to both manufacturer and customer by digital power control technology:

� No adjustable loop components to fail or become misadjusted.

� Wider stable operating ranges.

� Tighter unit-to-unit repeatability by eliminating loop inconsistencies caused by physical component tolerances.

� Downloadable personality changes/upgrades.

� Legacy supply retrofits with minimal or no test script changes.

� Reduced cost through capability to form virtual power components.

� Better self-diagnostics.

� Reduced system host demands.

� Automated manufacturing test and adjustment resulting in better consistency and lower cost.

Within the ReFlex Power product line, �regardless of product type�DC or AC supply or load�or model within a product type, the same control hardware is used, and the specific model personality is loaded at test. In fact,� Mr. Allen explained, �it is possible to load multiple personality images that may be selected to emulate specific legacy product responses within the limitations set by the converter hardware.�

Agilent�s Mr. Zollo stressed the need to optimize each model of a power supply family to minimize component stress and cost. �A standard design was digitally reprogrammed to create multiple models with the intention of achieving a fast time to market. However, because these products were not optimized, it was not economically feasible to continue their sales for several years. As a result, the range was redesigned as a set of lower cost optimized designs for limited operating ranges.�

Mr. Allen�s and Mr. Zollo�s points of view don�t necessarily conflict. To the degree that it�s economical to provide a common set of higher voltage switching devices and output capacitors, for example, one supply design can be programmed to do the job of two or more models within a range. Certainly, the control hardware can be identical across a range of supplies, but the high-power output components probably can�t be.

Nevertheless, substantial cost savings may be possible depending on the degree to which a manufacturer�s product ranges are similar. For example, in �Digital Power, A Manufacturer�s View� presented at the 2004 Digital Power Forum, Geof Potter of Astec Power stated, �In many cases, family variants are [distinguished by]�production-set parameters dictated by stuffing options or in-line adjustment. Protection thresholds, output voltage, input range control, and control-loop dynamics are among those parameters that seem destined to be tweaked more often in the future as designers build-in system optimization schemes. To the extent that such factors are programmed into an otherwise generic chassis,� he hypothesized, �savings can be realized in inventory management, change-order administration, and other complexity-dominated areas.�

Conclusion

In many applications with voltages dropping, tolerances tighter, and speeds higher, power supplies with greater precision and control will be required. The rate at which the balance shifts to digital control and the extent of the shift will depend on the cost-effectiveness of digital solutions.

In markets where digital control as an enabling technology has the greatest value, the rate of adoption will be greatest. ATE systems supporting multiple test regimens, component test involving high voltage or current slew rates, and standards compliance testing require the precision supply response, rapid and flexible reconfigurability, and more autonomous power subsystem capabilities of digital power supplies.

Why are manufacturers and their customers increasingly using digital power supply techniques? There are a number of answers, but the bottom line is better performance than an analog supply for a similar cost.

Reference

1. Valley, R., Digital Power: Teaming Digital and Analog for Today�s Power Systems, Texas Instruments, 2005.

August 2006