Vibration testing helps to predict how well a product will withstand its intended service or transportation environment. Some new vibration controllers have the capability to replicate data recorded while the product is being used. For example, the accelerations a vehicle�s suspension experienced on a bumpy road could be recorded and then played back to test car suspensions.

This technique has the advantage of providing vibration frequencies and intensities directly related to real service conditions. On the other hand, product resonances may not be exposed, nor can the test excitation be simply described.

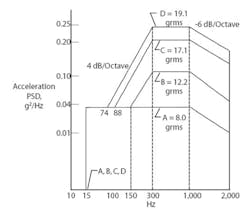

A second and very common approach is to specify a random vibration spectrum to which a product is subjected. Figure 1 shows four power spectral density (psd) curves that define part of NASA flight qualification for experiment hardware. NASA has modified an F-15B aircraft to carry a flight test fixture, and hardware must pass vibration testing before flying in the test fixture.1

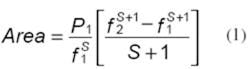

Curve A is the easiest to understand. The rectangular portion of this curve extends from 15 Hz to 1,000 Hz with a psd of about 0.039 g2/Hz. The area is 985 � 0.039 = 38.4 g2. The area under the downward sloping part of the curve from 1,000 to 2,000 Hz also contributes to the overall grms. To calculate this area, use the formula2

where: f1 = the lower frequency

f2 = the upper frequency

P1 = the psd level at f1

S = 0.3322 � slope (dB/octave)

For P1 = 0.039, f1 = 1,000, f2 = 2,000, and S = -6 � 0.3322 = -1.9932, area = 19.5 g2. Adding the two areas, 38.4 + 19.5 = 57.9, and taking the square root result in 7.61 grms, corresponding to the 8 grms on the figure.

One thing immediately noticeable in this example is the odd vertical scale on the psd plot. Usually, psds are log-log plots. This format accounts for the straight-line slopes labeled as so many dB/octave. On the other hand, finding an area under sloping straight lines requires the use of equation 1. Only for rectangular areas is the calculation straightforward.

The vertical axis above the 0.10-g2/Hz level has been expanded to more easily distinguish the four profiles from each other. However, because the total area under any one curve cannot be determined graphically anyway, it�s the clearly stated slopes and levels that are important.

For random vibration, the total force seen by the device under test (DUT) depends on the bandwidth. It�s convenient to use units of g2/Hz on these acceleration plots so that the overall grms acceleration is the square root of the total area.

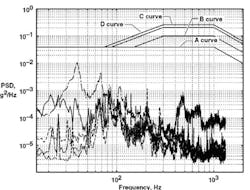

For comparison purposes, Figure 2 shows actual F-15B acceleration plots corresponding to takeoff, landing, steady climb, level flight, and descent. It�s easy to see that the vibration qualification profiles have a generous amount of safety margin built in, especially at high frequencies. Various peaks in the plots can be identified as engine noise, resonances in the flight test fixture, and possible vortex shedding from the nosewheel landing gear door. Some of the vertical difference between curves at lower frequencies is associated with the 10,000-lb fuel weight loss between takeoff and landing.

Figure 2. Actual F-15B Flight Test Data

Courtesy of NASA Dryden Flight Research Center

Establishing what effect caused which peaks is aided by a time history plot of acceleration. A psd profile says nothing about when a peak occurred, but a time history of the takeoff vibration shows, for example, the low-frequency intensity reduced after the landing gear door had been closed.

A Whole Lot Of Shaking Going On

Electrohydraulic

There is no one type of shaker that can accommodate all vibration profiles. For example, most of the energy associated with earthquakes is concentrated at low frequencies. To achieve high accelerations at these frequencies, correspondingly high displacements are required. Electrohydraulic shakers excel in seismic testing because they can provide a 10″ stroke and handle DUTs weighing tens of thousands of pounds. These characteristics are a perfect fit for Network Equipment Building System (NEBS) telecommunications equipment testing.

In addition to providing single-axis servo-hydraulic shakers used for seismic and shock testing, Team Corporation has developed multi-axis shakers. Most companies still test products one axis at a time, but many studies have concluded that this technique lacks realism. Faults found under actual operating conditions often vary from those exposed by sequential single-axis vibration testing.

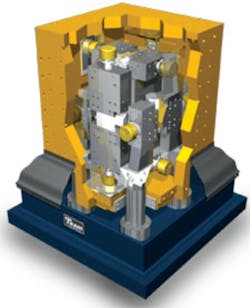

Figure 3. Cutaway View of 6 DOF CUBECourtesy of Team Corporation

The CUBE� from Team Corporation couples three pairs of actuators in a compact configuration capable of six degrees of freedom (6 DOF) motion over a bandwidth of 250 Hz and for DUTs up to 1,000 lb (Figure 3). Force ratings from 3,000 to 14,000 lb in each axis combined with controlled sine, random, or replicated time history vibration address applications such as automotive durability and suspension testing, squeak and rattle testing, and multi-axis screening of electronic components and modules.

For accurate higher-frequency 6 DOF testing, the newer Tensor� Vibration Test System drives 100-lb payloads at up to 1,000 Hz. In addition to the company�s actuator design expertise, Team holds patents on innovative hydrostatic bearing technology, fundamental to coupling multi-axis motion in a 6 DOF shaker.

Mechanical

Mechanical shakers, sometimes called mechanical reaction shakers, also are suitable for low-frequency testing. Because of its low cost, this technology is widely used for loose-part testing, resonant searches, and design qualification. Test systems manufactured by M/RAD can perform linear or log sweeps between 8 Hz and 60 Hz.

The company�s vice president, Jeffrey Marshall, said, �Mechanical shakers often are used to simulate vibration environments such as those encountered when shipping a product. The most common package test specification requires a 1″ peak-peak displacement at a frequency between 2.5 and 5 Hz so that the test specimen separates from the table by 1/16″. This bounce test will result in greater than a 1-g acceleration output from the machine and 6 to 10 g between the table and the test specimen.�

ANCO Engineers also produces economical mechanical shakers. Dr. Paul Ibanez, the company�s president, said, �The shakers we offer are eccentric mass vibrators ranging in force capacity from a few pounds to over a million pounds. They cover the frequency range from approximately 0.1 Hz to 300 Hz and typically are used for sinusoidal testing of large civil structures such as piping, machine foundations, dams, buildings, and bridges.

�We also provide multi-axis tables driven by eccentric-cam, servo-hydraulic, or servo-motor actuators. The payload ranges from 1 lb to more than 50 tons with frequencies up to 500 Hz. These systems typically are used for earthquake engineering research, transportation vibration research, or flight and automotive vibration studies,� he continued.

An important limitation of a mechanical shaker is production of one frequency at a time. Because many machines of this type are based on reaction to a rotating eccentric mass or direct drive from a rotating cam, the resulting motion will be at a single frequency. This is the reason for Dr. Ibanez� reference to sinusoidal testing. In general, this type of shaker does not provide random vibration.

Repetitive Shock

Another type of shaker is the repetitive-shock 6 DOF vibration table. In this approach, a softly sprung platform moves in response to pneumatically driven actuators mounted at several different angles and attached to the bottom of the platform. The end result is a relatively low-cost means of achieving random acceleration. The simple and physically compact actuating mechanism makes it easy to combine these platforms with temperature chambers for HALT/HASS testing.

In many cases, the platform is not sufficiently rigid to ensure uniform acceleration across its total area. When multiple DUTS are being tested, monitoring is needed in several locations to achieve good correlation between test results and actual applied acceleration.

According to Doug Mahn, senior vibration application engineer at Thermotron, the company recently introduced a line of repetitive shock vibration tables with enhanced low-frequency performance. Most tables of this type concentrate energy at higher frequencies, but the new RSL line provides 48% more energy at 1,400 Hz than previous designs. Good acceleration uniformity also is a claimed feature of these tables, which range in size from 16″ � 16″ to 48″ � 48″.

Electrodynamic

A few electrodynamic machines, such as Unholtz-Dickie�s LS Series Horizontal Thrusters, have a stroke up to 24″long. These are used in automotive crash test applications, for example. The more conventional electrodynamic shakers are the most versatile vibration testing solution and typically have a 2″ to 3″ stroke.

Electrohydraulic shakers handle low frequencies up to 150 or 300 Hz. Electrodynamic shakers are effective to 2,000 Hz, and special models can be used to more than 5,000 Hz for smaller DUTs. Many test labs use a combination of electrohydraulic and electrodynamic machines to cover the entire range of frequencies likely to be encountered.

This type of shaker can provide very accurate levels of random acceleration closely corresponding to test profiles such as those shown in Figure 1. This feature distinguishes electrodynamic shaker systems from repetitive shock-actuated 6 DOF tables, which cannot be controlled accurately, especially at low frequencies. Conversely, these 6 DOF machines provide three axes of rotation and three of displacement very economically. There is a trend toward two- and three-axis electrodynamic shaker testing similar to Team�s multi-axis servo-hydraulic capability, but these are much more expensive solutions.

In addition to only random or only sinusoidal vibration testing, specifications call for different combinations such as sine-on-random, which is suitable for testing vehicles. The sinusoidal vibration corresponds to frequency components produced by the rotating engine and drivetrain while the random part provides vibration similar to that caused by the road surface. An electrodynamic shaker can perform all these types of tests if suitably driven.

These shakers operate on the same principle as a loudspeaker in which a voicecoil moves within a magnetic field. Of course, many shakers are huge in comparison. The cylindrical armature in a large electrodynamic shaker can be 25″ in diameter and weigh more than 100 lb. Nevertheless, stationary field coils provide an intense DC magnetic field within which the armature moves because of the interaction between this field and the current driving the armature coil.

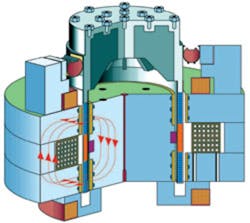

Figure 4. Cutaway View of V9 Series Shaker Showing Dual-Coil ArmatureCourtesy of LDS Test and Measurement

The V9 Series Shakers manufactured by LDS Test and Measurement use an armature consisting of two coils on a common carbon-fiber former bonded to a magnesium frame (Figure 4). Sukhi Dhillon, product manager-test systems at the company, commented on the shaker design:

�In a conventional shaker, there is one flux gap with two opposing field coils to provide the driving force. The V9 design essentially reverses this, using one field coil driving two magnetic gaps. This means that the armature can be shorter and lighter, and displacements can be increased for a given size shaker [because the shorter armature will stay within the magnetic field.] Also, because the two magnetic flux gaps are less heavily saturated, higher velocities are achievable.�

By having two coils, rotational torque on the armature due to the vertical component of coil current can be cancelled. By far, the greatest force results in the axial direction; however, a separate rotational force exists due to the axial current flow from one end of the coil to the other. For the axial forces from both coils to add, current must flow through them in the same direction relative to the field orientation. The coils and currents can be arranged so that the forces due to axial current flow cancel while the axial forces add.

Larger V9 Shakers are water-cooled to ensure consistent performance during very long tests at maximum force levels. In addition, an integral air suspension provides effective isolation and simplifies installation.

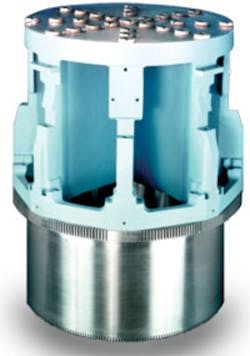

Rather than having an armature coil wound with copper wire, the Induct-A-Ring (IAR) Shakers from Unholtz-Dickie use a solid aluminum ring (Figure 5). Currents are induced in the ring by inner and outer stator coils. As in a conventional shaker, motion results from the interaction of this current with the strong DC magnetic field.

The solid single-turn coil has many advantages, most of them related to peak performance and durability. For example, the largest shaker in the series, the T5500, is rated to deliver 110,000 lb shock and 55,000 lb force for either random or peak sine vibration. The T5500 has a solid copper ring instead of the aluminum ring used in lower-force models.

This kind of performance isn�t free, and two of the major considerations in large shakers are power and heat. Because there is no insulation used in the IAR armature, it can endure long periods of use at high dissipation. For example, catalytic converters weighing 85 lb were tested without pause for 72 h at 75-g peak acceleration by an IAR T2000 Series Shaker.

Power amplifier modules for the IAR Shakers are rated to 480 kVA. Even though class D switching technology keeps losses to a minimum, suitable cooling provisions must be made when installing a large shaker system. There also is the cost of power to consider.

Unholtz Dickie provides energy-efficient operating modes that run the IAR field coils at half of the full rated power but with up to 85% of rated shaker force. Thermotron�s VCS-3200 Vibration Control System also optimizes shaker power consumption, forcing a shaker system to run more cost effectively.

You may not require such extremes of performance, although LDS Test and Measurement�s Mr. Dhillon has noticed that customers are testing larger and larger payloads. �We have seen this trend in a number of industries from satellite testing through to consumer electronics. In consumer electronics, the aim is to be able to test larger quantities of units in a single test. The growth of cell phones, MP3 players, and other consumer electronics has driven this requirement, and bigger shakers address the need. Similarly, satellites have continued to increase in size and here, too, larger systems are necessary.�

|

FOR MORE INFORMATION |

| ANCO Engineers | Mechanical Shakers | www.rsleads.com/701ee-192 |

| LDS Test and Measurement | V9 Series Shaker | www.rsleads.com/701ee-193 |

| M/RAD | Mechanical Shakers | www.rsleads.com/701ee-194 |

| Unholtz-Dickie | Induct-A-Ring Shaker Technology | www.rsleads.com/701ee-195 |

| Team | CUBE 6 DOF Shaker | www.rsleads.com/701ee-196 |

| Thermotron | RSL Repetitive Shock Table | www.rsleads.com/701ee-197 |

| Vibration Research | Variable Kurtosis Controller | www.rsleads.com/701ee-198 |

Whatever the size of shaker, for random vibration, its capacity directly relates to the psd plot. The shaker force rating must exceed the product of the grms requirement and the total mass being shaken including the shaker armature and any fixture that may be used. For example, if an experiment to fly on NASA�s F-15B weighs 300 lb and a fixture and shaker armature add 200 lb more, a shaker with at least a 4,000-lb rms force rating is required to test to the 8 grms of profile A.

Making Those Good Vibrations

To generate truly random vibration, most controllers attempt to create a Gaussian probability distribution function (pdf). As useful as random vibration testing is, it often fails to adequately reflect the accelerations experienced by DUTs in actual use. In particular, there may not be a sufficient number of large excursions generated.

The Kurtosis parameter describes the shape of a distribution�s tails and can be programmed on some controllers to overcome this problem. A higher Kurtosis value corresponds to more energy provided by infrequently occurring events. The distribution�s tails become fatter because these events occur more often than in a Gaussian distribution.

Vibration Research makes a controller that can be programmed to produce different amounts of Kurtosis. John Van Baren, the company president, commented, �Gaussian distributed random vibration may be too conservative for some product/environment combinations. The test does not produce the same damage acceleration transients observed in the field. Adding a Kurtosis control dimension provides more realistic random tests that better match the damage potential of the actual environment.�

Skewness, a second parameter, describes the symmetry of the distribution. For example, the characteristics of a truck suspension may cause more severe acceleration in the downward direction than upward. Adjusting skewness will cause the vibration controller to produce an average psd that takes this effect into account.3

A Gaussian pdf implies infinitely high acceleration if you wait long enough. Obviously, a physical shaker cannot produce greater than some well-defined maximum force. Many shaker manufacturers solve this conflict by limiting the fidelity of the vibration distribution produced to three sigma. In other words, the maximum g force produced will be up to three times the rms value.

Statistically, this restriction affects only about 0.5% of the distribution�the very infrequent large events far out on the tails. For 99.5% of the time, a true Gaussian distribution is provided. The difference between 99.5% and 100% becomes important in nonGaussian distributions having higher kurtosis values.

Forces greater than three sigma are required, and forces greater than one sigma will be produced more often. These considerations may not significantly affect the average force the shaker produces, but they do imply that the shaker and controller combination must handle peak forces many times greater than for a Gaussian distribution.

Summary

Vibration testing has become quite sophisticated. Not only are specifications mixing random and random or sine and random excitation, but the detailed shape of a distribution also can be altered to suit. Modern DSP-based vibration controllers have made possible custom distributions that attempt to better match real-world environments.

Nevertheless, beyond these refinements, most vibration test fundamentals haven�t changed. You still need to understand the relationship of your shaker to the device being tested and the specified tests. The shaker must have the necessary frequency response and force rating. But, frequency response means different things depending on whether acceleration, velocity, or displacement is most important.

Shaker performance is bounded in all three parameters, typically over different frequency ranges. Except for specialized seismic test models, even the most powerful electrodynamic shakers are limited to 2″ or 3″ maximum displacement. That value bounds performance at low frequencies. At higher frequencies, limits on armature velocity come into play, and at even higher frequencies, acceleration becomes the limiting factor. Once you understand a manufacturer�s spec sheet in detail, shaker selection is a matter of taking into account all the relevant factors.

References

1. Corda, S. et. al., �In-Flight Vibration Environment of the NASA F-15B Flight Test Fixture,� NASA/TM-2002-210719, 2002, www.nasa.gov/centers/dryden/pdf/88734main_H-2468.pdf

2. Random Vibration Testing, Labworks, www.labworks-inc.com/enginfo/random_vib_test.htm

3. Steinwolf, A., �Closed-Loop Shaker Simulation of Non-Gaussian Random Vibrations,� Test Engineering and Management, July and October, 2006.

January 2007