An important key to making good measurements is to choose instrumentation with input characteristics that complement those of the signal. The input to a measuring instrument or data acquisition (DAQ) system typically has two or three terminals: the signal and its return if single-ended or two signals and their reference if differential. Similarly, a signal source has two terminals if single-ended and three if differential. The instrument can have additional guard or shield terminals, but they don’t affect the basic operation.

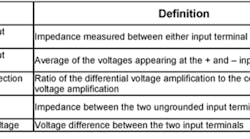

Table 1 lists the differential and common-mode voltages and impedances that relate to an amplifier’s input characteristics. Similar terms describe the signal source output. They both have common-mode impedance, common-mode voltage, differential impedance, and differential voltage. The source output must be compatible with the instrument’s differential and common-mode voltage ranges and impedances as well as the reference level. A hierarchy of input types helps you to trade-off cost vs. performance.

Table 1. Differential and Common-Mode Definitions1

Source: Texas Instruments

Regardless of the input configuration, the instrument bandwidth must be sufficient to handle the signal frequencies. In addition, the frequency dependence of specifications such as CMRR also may be critical in an application.

Input Configurations

Single-Ended

The lowest cost configuration is a single-ended, unbalanced, grounded input. In spite of its limitations, this type of input is found on a wide variety of test instruments and DAQ systems. It works well with a floating source that has relatively low differential impedance. The IN+ terminal impedance to ground must be high in comparison to the source differential impedance to avoid loading.

For ground-referenced sources, this type of input implies that the signal and instrument grounds must be identical. Of course, the two voltages generally won’t be exactly the same, but if the levels are close to each other and the signal relatively large, you can make the measurement.

Depending on the difference in ground voltages and impedances at the source and the instrument, significant current can flow, creating an error voltage that adds offset to the measurement. In the best case, your measurement simply will be noisy. In the worst case, the instrument will be damaged or destroyed. Single-ended inputs help to create ground loops that are the cause of many measurement problems.

In general, a single-ended input cannot be used with a differential source that is not floating. Separate single-ended inputs can be connected to each of the source terminals and the two outputs subtracted. This approach only works if each input channel can handle the common-mode voltage plus the differential signal range. Attenuating probes can be used with two scope channels to increase the common-mode range at the expense of reduced differential-mode sensitivity.

The Elsys Instruments series of transient recorders features high speed and 14-bit or 16-bit resolution with single-ended inputs that can be paired for differential operation. Attenuation scales input signals to fall within the typical 8-V CMV range to retain compatibility with the ground-referenced amplifiers.

QDAC’s approach focuses on high resolution and low noise. Bjarni Tryggvason, founder and CTO, explained, “The QDAC data system provides a power source individually to active sensors or accepts input from passive sensors. These power sources are designed to provide very clean power…. Wiring to sensors includes separate ground wires for each sensor to avoid mixing sensor and power return currents….”

The company’s DAQ hardware has single-ended or differential ground-referenced 5-V inputs with 100-kS/s aggregate sampling rate and 10-kHz bandwidth. Input impedance is 200 kΩ single-ended or 400 kΩ differential. Oversampling and digitally filtering the basic 14-bit or 16-bit ADC data both improve resolution and reduce noise.

Differential

A differential input is balanced because the gains and impedances of the two inputs are the same. Neither input is directly connected to ground so a differential input can deal with single-ended grounded or off-ground differential sources. Nevertheless, there is a limit to the maximum signal that each input can handle because the amplifiers are referenced to ground.

For example, a signal source might have a +5-V CMV and a differential signal of 5 V. The voltage difference between the two source terminals varies between 0 and +10 V so each input must have a range of at least 10 V or else the signal will be distorted.

As long as the largest signal excursions relative to ground lie within a differential input’s common-mode and differential-mode capabilities, the measurement system should work correctly. Problems typically occur when you need to measure a small differential voltage on a high CMV. Attenuation of both sides of the source signal can be a solution but sensitivity is lost. Also, unless the attenuators are well matched, the CMRR will be reduced.

For a floating source, a high value resistor is added between one side of the source and the input’s reference—in this case, ground—to ensure that the source voltage remains within the input’s range. The practical limit on the resistor size is determined by the input bias current.

Instrumentation amplifiers are a form of differential amplifier that has very high common-mode rejection. A typical three-op-amp circuit performs several functions that enhance its performance. The two identical and high-impedance input amplifiers provide differential-mode gain but reject the common-mode part of the source signal. This means that the third amplifier, configured as a subtractor, only contributes part of the overall CMRR. This is in contrast to the previous two-channel scope-probe example in which all the common-mode rejection was determined by the subtractor accuracy and probe and channel matching.

Isolation

Signal interfacing problems often occur because of incompatibility with the instrument input reference. An isolated input resolves these issues by allowing the channel reference to accommodate the input signal. Because the input is isolated from everything else, it will float to the source output level.

The limitations of older analog implementations that transferred the input signal across the isolation barrier have been overcome by modern digital isolation schemes. In these, the input amplifier and associated ADC are driven by an isolated power supply. The digital output from the ADC can be transferred across the isolation barrier at high speed and with virtually no degradation. Similarly, because a PC may not have the same ground as the DAQ system it’s being used with, the various bus outputs for PC data transfer and control also are isolated.

Lawson Labs founder and president Tom Lawson explained, “Lawson Labs concentrates on 24-bit, high accuracy A/D [conversion]. Any isolation placed between the signal and the A/D converter will immediately dominate the noise and nonlinearity of the system. The preferred alternative is to place the A/D converter on the isolated side and use digital isolation for the converted data.”

For the GX2065 6½-digit DMM/digitizer PXI card recently introduced by Geotest-Marvin Test Systems, several challenges had to be overcome. As described by Mike Dewey, the company’s senior product marketing manager, “The front end not only had to be isolated, but also had to meet high-voltage isolation/protection requirements as defined by IEC 61010-1, CAT II, 300 V, pollution degree 2 specification. We ended up using some unique techniques to meet the high-voltage protection and isolation requirements associated with a DMM.”

Because a PXI module runs from ground-referenced DC voltages distributed throughout the multislot chassis, Geotest used a push-pull forward converter to provide an isolated voltage for subsequent DC-DC converters that supplied the DMM’s ± rails. After low-pass filtering, these voltages were applied to linear regulators to generate the low-noise supplies needed for a high-resolution DMM. Similar attention to detail was required throughout the design to satisfy conflicting power, safety, noise, cost, and space constraints. The design is discussed in detail in reference 2.

An isolated input can either be single-ended or differential, but both configurations are referenced to the isolation supply voltage common rather than ground. For a multichannel instrument with single-ended, isolated inputs, a measurement on channel 1 may be affected by the signal on channel 2 if the signal CMVs are significantly different.

If the channels are isolated from ground but not from each other, the common voltage can float off ground, but all the channels must have the same common reference. All isolated differential inputs also may be referenced to the same common voltage. This configuration is more flexible but still only accommodates multiple signals if all fall within the common-mode and differential-mode voltage limits.

The most universal input configuration separately isolates each channel. This means that one input signal can be a 3.3-V logic signal referenced to ground while another input is a millivolt-level signal from a current shunt referenced to several hundred volts AC. With channel-to-channel as well as channel-to ground isolation, there is no interference between channels. The choice of single-ended or differential still makes a difference in applications that need the higher CMRR provided by an isolated differential input.

Dewetron’s president Grant Smith described an application that required both channel-to-channel and channel-to-ground isolation. “The engineers at an electric car company needed to measure the battery voltage and current outputs under a wide variety of loads and operating conditions, and they also needed to watch the temperature very carefully at multiple locations. Some of the best locations to measure happened to be on terminals and other places where the potential was quite high.

“Dewetron’s isolated CPAD series thermocouple and RTD conditioners provided our customer 350-V isolation on each input, channel-to-channel and channel-to-ground, so they could make their measurements without any fear that the thermocouple’s tiny output would be overwhelmed by the potential at the measuring point.” He concluded, “Without isolation, there would be no way to make the measurement. Infrared cameras would never fit in the compartment, nor would they survive the operating conditions for long.”

Grounding

Choosing the input configuration that best suits an application is only part of the job. A DAQ system has to coexist with the equipment being tested. Microstar Laboratories’ Larry Trammell, technical marketing director, explained, “We distinguish three related but different aspects of signal protection with different goals: grounding to provide strong paths for power return current and static discharge so that the noisy stray currents are not diverted through signal leads, shielding to avoid radiated interference from coupling into signal paths, and isolation to cut off stray paths for ground-return current flows when source and destination operate at different potentials.”

Lawson Labs’ Lawson elaborated, “Isolated circuits require their own common connections. These isolated common connections are sometimes referred to as grounds. The confusing nomenclature can contribute to installation problems. In any event, the customer must get used to the fact that not all ‘grounds’ are the same potential, and they often are not interchangeable.

“The notion of DC common-mode range can be another sticking point,” he continued. “True differential, high-impedance inputs are capable of extreme accuracy, but only if properly applied. There often is a strong tendency to ground the negative input terminal since ‘it’s at ground, anyway.’ The correct approach is never to allow ground currents to flow in high-impedance input wiring. Always provide a separate ground path.”

Further confirmation of the need to carefully plan a DAQ system’s grounding scheme was provided by Roger Lockhart, vice president at DATAQ Instruments. “Much to the chagrin of many customers, ground is not absolute. In industrial measurements, ground is indeed a relative term, and it’s the rare application that does not have various ground references at different relative potentials. It’s only a matter of magnitude,” he emphasized. “Isolated instruments resolve the problem nicely, provided that the potential differences are within its isolation spec. Even a differential amplifier can help, provided that off-ground potentials remain within its common-mode range.”

Isolation Techniques

According to Brian Phillippi, C Series I/O product marketing engineer at National Instruments (NI), the company’s isolated C Series modules feature isolation based on Analog Devices’ iCoupler technology. As shown in Figure 1, an iCoupler channel has three main parts: the transmitter; a planar, well-insulated transformer; and a receiver. Transformers are inherently differential and naturally provide common-mode transient rejection.

Figure 1. iCoupler Block Diagram

Courtesy of Analog Devices

Phillippi described the operation. “The transmitter circuit uses edge trigger encoding and converts rising and falling edges on the digital lines to 1-ns pulses,” he said. “These pulses are transmitted across the isolation barrier using the transformer and decoded on the other side by the receiver circuitry. The small size of the transformers, about three-tenths of a millimeter, makes them practically impervious to external magnetic noise. iCoupler devices also can lower measurement hardware costs by integrating up to four isolated channels per integrated circuit and, compared to optocouplers, they require fewer external components.”

In a comparison of optocouplers to the iCoupler, an Analog Devices technical article stated, “Optocouplers… [consume] high levels of power and [limit] data rates to below 1 Mb/s. More power-efficient and higher-speed optocouplers are available but impose a higher cost penalty.”3 Nevertheless, a number of optical isolation techniques are used, each with its own benefits.

A Data Translation white paper noted that optoisolation is subject to long-term drift. Used to transfer digital data, this factor isn’t too important although it certainly is for analog signals. The paper also discussed the company’s ISO-Channel technology in broad terms.

As the name implies, each channel is isolated from all the other channels as well as from ground. “With ISO-Channel technology, the A/D is on the sensor side and optical or transformer isolation is used to transfer the sensor data digitally. Each channel has its own custom DC/DC converter so that data is converted even at low power levels. And, due to the simultaneous architecture of ISO-Channel technology, all data is transferred in parallel.”4

Omega Engineering has taken a slightly different approach in the Ethernet-based 12-channel OMB-NET6230 isolated analog voltage input DAQ modules. The 12 channels are powered in groups of four, but each channel is separately isolated from power, ground, and other channels. The instrument features 24-bit ADCs and optical isolation with 250-Vrms galvanic channel-to-channel isolation for increased signal integrity and to eliminate ground loops.

A Yokogawa white paper described the company’s isoPRO technology that uses optical fiber-based transmissions to achieve speeds up to 100 MS/s together with 1,000-Vrms isolation. As shown in Figure 2, “isoPRO technology employs a system whereby digital data is converted to optical using a semiconductor laser diode, and the data is transferred via optical fiber to the instrument.… As the data transfer rate of the semiconductor laser diode is extremely high, large amounts of data can be transferred on a single device, and as a result, the area of isolation has become very small. Also, due to the fact that optical fiber itself is an insulator, and that the distance of signal transfer along the optical fiber is of a sufficient distance for the requirement of insulation, an insulating distance between the signal input and the main unit is provided even at a high voltage of 1 kV.”5

Figure 2. isoPRO Technology as Used in the DL850 ScopeCorder

Courtesy of Yokogawa

To meet regulations governing the safety of electrical equipment, both the insulation built into the isolation device as well as the physical creep distance between PCB connections must be adequate. In Yokogawa’s case, the length of the optical fiber satisfies the specification. Analog Devices uses the SOIC16W package for its range of iCouplers, providing the 8-mm creepage distance required in some applications.

HBM’s optical-fiber-isolated ISOBE5600 supports DAQ under extreme conditions. A transmitter with up to four channels is either battery powered with no connection to ground or mains powered with 10-kV isolation. Each channel has 20-MHz bandwidth and converts the analog inputs to a digital form suitable for optical fiber transmission. The receiver accepts the output from the optical fiber and uses a 14-bit DAC per channel to reconstruct the original analog waveforms.

This system supports up to a 50-m separation between transmitter and receiver or as little as 3 m. Very high-voltage applications can be addressed, and the 1-MΩ transmitter input impedance allows the use of conventional scope probes. Of course, all probe leads and the transmitter itself must be physically distant from ground to take full advantage of the 1015-Ω/m isolation that the optical fiber link provides.

Applications

Thermocouple-based temperature measurement was mentioned by several vendors as a typical isolation application. Agilent Technologies’ Model 34972 LXI data acquisition/data logger switch unit features isolation at several levels. As explained by Bill Griffith, application lead at the company, “The 34970A [GPIB and RS-232 I/O] and 34972A [LXI I/O] use optical isolation between the measurement circuitry and the interface circuitry, which provides 300 V of isolation and reduced common-mode noise. The equivalent circuit to ground has an impedance greater than 10-GΩ and 250 pF….” He concluded, “The logic is divided into two parts: one is ground referenced and the second floats. The floating logic is extended out to the modules via an isolated communications bus.”

The modules, such as the 34901A multiplexer, retain the built-in DMM’s 300-V channel-to-channel and channel-to ground isolation. This module supports 2-wire or 4-wire multiplexing of 20 channels at a scanning speed of 60 ch/s. In contrast, the 34908A multiplexer handles 40 single wire channels. Because all 40 sources have the same common connection, a datasheet footnote stated “thermocouple measurements not recommended with 34908A module due to common to configuration.”

NI’s Phillippi noted that the majority of the more than 60 I/O modules compatible with NI’s CompactDAQ and CompactRIO products have some form of isolation, often to 300 Vrms with transient levels up to 2,300 V. The NI 9239 four-channel module with differential inputs and channel-to-channel isolation is shown in Figure 3. Four isolated C Series modules support thermocouple measurements, and the NI 9211 features built-in cold junction compensation for increased accuracy.

Figure 3. NI 9239 Analog Input Module

Courtesy of National Instruments

United Electronic Industries’ Bob Judd, director of marketing, also discussed temperature measurements. “Perhaps the most common place where channel-to-channel isolation is required is in the monitoring and control of large electric motors. Thermocouples often are connected directly to the motor components, which may see a common-mode voltage of a few hundred volts or more. Connecting a multichannel, nonisolated device in such an application is almost certain to damage the DAQ input.”

Judd commented that even if the references for several signals are nominally at ground, tying those grounds together can lead to nightmarish ground loops and noise issues. Isolation keeps the grounds separate and eliminates interference from one to another.

Reference

1. “Chapter 11: Understanding Op Amp Parameters,” Texas Instruments, Literature Number SLOA083, pp. 2, 3.

2. Robins, J., and Dewey, M., “Incorporating Advanced Instrumentation Capabilities into a PXI Digital Multimeter Instrument,” IEEE Autotestcon 2012 Proceedings.

3. Krakauer, D., Anatomy of a Digital Isolator, Analog Devices, Technical Article MS-2234, 2011, p. 1.

4. Why ISO-Channel Technology Is Your Best Return on Investment, Data Translation, Application Note, p.6.

5. Nakayama, E., The DL850—The Ideal ScopeCorder for Developing Energy-Saving Devices, Yokogawa Meter & Instruments, p. 2.