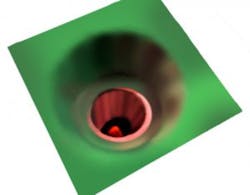

Jena, Germany. The 3D·EyeZ sensor system from GOEPEL electronic supports a range of applications in electronics manufacturing due to its shadow-free measurement. The unique design allows for the measurement of the press-in depth of press-fit connectors mounted on PCBs. It is possible to directly measure inside the drill-holes of the printed-circuit board and determine the position of the pin tip within the PCB material. Even in holes with a diameter of up to 200 µm, the exact position inside the drill-hole can be measured with an accuracy of up to 5 µm.

This level of quality control is required, for example, to insure proper electrical functionality of this type of plug-in connector when used for high-frequency data transmission in telecommunications applications.

In addition to this application, 3D·EyeZ allows circumference and set depth inspection of conventional connector pins on PCBs. Possible test functions are control of the x-y deflection and measurement of the pin height.

Despite the increasing miniaturization and ever higher integration density on electronic assemblies, plug connectors are still an important part of assembled components. In addition to solder joints and polarity, correct assembly and mechanical properties of the individual pins are of critical importance for quality assessment.

The 3D·EyeZ measurement module is, together with the orthogonal camera and the rotating angled-view module Chameleon, optionally available for the AOI systems from GOEPEL electronic, both in-line and stand-alone.