Fluid-Cooled Cable Quadruples EV Charging-Current Capacity

What you’ll learn:

- A new cooling technology has been proposed for EV high-current charging cables.

- The system relies on the use of subcooled flow boiling to remove the heat from the cable.

- Experiments were performed to acquire data for subcooled boiling in annuli using HFE-7100 as coolant.

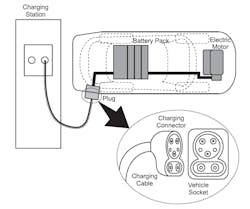

Many challenges persist when it comes to reducing the charging time for electric vehicles (EVs). These include the amount of power available at the charging station, the charging station’s power-conversion electronics, the cable carrying the power from the charging station to the vehicle, and the charging subsystem within the vehicle itself (Fig. 1).

Each of these barriers requires new approaches and solutions, likely to be addressed by different industry specialists. Of course, when it’s about charging currents of several hundred amperes and up, every solution requires thorough analysis, testing, and vetting to make sure it works well, works reliably, and works safely.

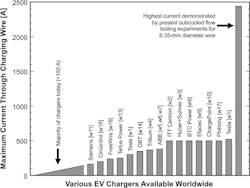

Clearly, the amount of current delivered to the EV is an important factor in determining required charge time. A team at Purdue University is focused on that charging cable and has analyzed, devised, and tested a way to increase the current-carrying capacity from its present maximum of 520 A to over 2400 A. They note that the 520-A figure is the highest by far, as many chargers fall well below that (Fig. 2).

The cooling benefits make it possible to use a smaller wire diameter inside the charging cable and dissipate a higher current, while removing a little over 24 kW of heat. “My lab specializes in coming up with solutions for situations where the amounts of heat that are produced are way beyond the capabilities of today’s technologies to remove,” said Issam Mudawar, Purdue’s Betty Ruth and Milton B. Hollander Family Professor of Mechanical Engineering.

Fluid-Based Cooling

To achieve this significant increase in capacity, the team employed fluid-based cooling of the cable, as even a minuscule amount of unavoidable resistance in the cable and its connectors results in a large amount of I2R heating. The team accomplished this via rigorous fluid and thermal modeling, detailed equations, and additional insight into the dynamics of cooling,

The project began with a basic thermal model of the cable (Fig. 3), but that doesn’t begin to reveal the subtleties and real-world considerations they took into account as the fluid-dynamics modeling progressed. They added complex equations characterizing the system dynamics from multiple perspectives to advanced modeling and subsequent simulation toolkit.

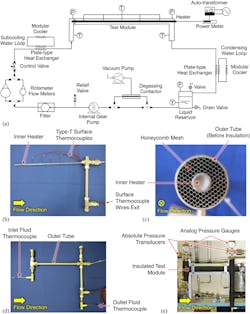

Their objective was to develop a consolidated theoretical/empirical method for predicting the heat transfer and pressure drop characteristics of both laminar and turbulent flows though concentric circular annuli with a uniformly heated inner wall and adiabatic outer wall. By capturing heat in both liquid and vapor forms, a liquid-to-vapor cooling system can remove at least 10X more heat than pure liquid cooling.

Although maintaining subcooled boiling along the entire cable is a key practical objective, this consolidated method is shown to be capable of tackling multiple flow regimes (single-phase liquid, subcooling boiling, saturated boiling, and single-phase vapor). Their model is highly effective at predicting local surface and fluid temperatures.

Building and Testing the Model

While it’s one thing to model and simulate regardless of sophistication, it’s another to build and test what these indicate. The team’s arrangement involved pumping highly subcooled dielectric liquid HFE-7100 though a concentric circular annulus mimicking a segment of an actual cable. A uniformly heated 6.35-mm-diameter inner surface represented the electrical conductor and adiabatic 23.62-mm-diameter outer surface for the external conduit.

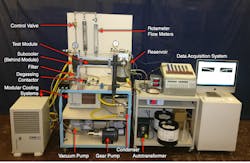

At such levels of power, heat, and fluid flow, the basic plumbing itself is complicated, as are the various transducers needed to control and measure and the parameters of interest (Figs. 4 and 5).

Although the prototype hasn’t been tested on EVs yet, Prof. Mudawar and his students demonstrated in the lab that their prototype accommodates a current of over 2.4 kA. (Note that he has been working for 37 years on ways to more efficiently cool electronics by leveraging how liquid captures heat when boiled into a vapor; by capturing heat in both liquid and vapor forms, a liquid-to-vapor cooling system can remove about an order of magnitude more heat than liquid cooling alone.)

Their prototype mimics all of the traits of a real-world charging station: It includes a pump, a tube with the same diameter as an actual charging cable, the same controls and instrumentation, and maintains the same flow rates and temperatures (Fig. 6).

For More Details…

The work is described in extreme detail in two somewhat overlapping papers, each of which is among the longest ones I have ever seen in any academic journal. The papers include copious analysis, modeling data, detailed tables, insight, and results. They also thoughtfully include a full page defining all the nomenclature, Greek symbols, subscripts, acronyms, and abbreviations used.

The two papers with lengthy titles, but just three authors, are “Experimental investigation of subcooled flow boiling in annuli with reference to thermal management of ultra-fast electric vehicle charging cables” (20 pages) and “Consolidated theoretical/empirical predictive method for subcooled flow boiling in annuli with reference to thermal management of ultra-fast electric vehicle charging cables” (22 pages). Both are behind paywalls, but accessible copies are posted at the Two-Phase Flow and Thermal Management Laboratory (TPFTML) web page of the Gwangju Institute of Science and Technology (South Korea) here.

The project was funded by a research and development alliance between Ford Motor Co. and Purdue. The researchers have filed a patent application for their charging cable invention.

About the Author

Bill Schweber

Contributing Editor

Bill Schweber is an electronics engineer who has written three textbooks on electronic communications systems, as well as hundreds of technical articles, opinion columns, and product features. In past roles, he worked as a technical website manager for multiple topic-specific sites for EE Times, as well as both the Executive Editor and Analog Editor at EDN.

At Analog Devices Inc., Bill was in marketing communications (public relations). As a result, he has been on both sides of the technical PR function, presenting company products, stories, and messages to the media and also as the recipient of these.

Prior to the MarCom role at Analog, Bill was associate editor of their respected technical journal and worked in their product marketing and applications engineering groups. Before those roles, he was at Instron Corp., doing hands-on analog- and power-circuit design and systems integration for materials-testing machine controls.

Bill has an MSEE (Univ. of Mass) and BSEE (Columbia Univ.), is a Registered Professional Engineer, and holds an Advanced Class amateur radio license. He has also planned, written, and presented online courses on a variety of engineering topics, including MOSFET basics, ADC selection, and driving LEDs.