"Cap-Drop" Approach Implements Offline Power Supply for Light Loads

This file type includes high-resolution graphics and schematics when applicable.

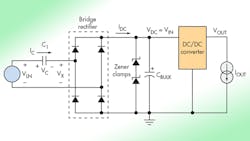

Low-power applications such as e-meters (electricity or energy meters) often require a simple ac line-powered supply where a 3.3-V rail powers a microcontroller and charges a lithium-ion battery to 4.2 V. You can implement this with a mains-frequency power transformer or with a more complicated ac-dc (offline) power supply. Both approaches have well-known disadvantages related to a combination of weight, size, and complexity. Two simpler options are a full-wave capacitor-drop circuit with the bridge rectifier (Fig. 1) and similar half-wave circuit.

The front end of these circuits is known as a “capacitive-dropper” or “cap-drop” topology. The idea behind both the full-wave and half-wave implementations of this circuit is that line capacitor C1 acts as a lossless resistance, and the reactance of the capacitor will set the maximum current that can be provided to the input of the dc-dc regulator.

The Zener diodes clamp the input voltage to the dc-dc converter under no-load conditions, thus converting the mains voltage to an intermediate dc rail (VDC). The input voltage to the dc-dc converter (VDC = VIN) is set to a relatively high value so that the current required from the cap-drop will remain low. You can then downconvert the intermediate unregulated dc rail to the regulated dc voltage required by the load by using a buck regulator with a wide VIN range.

A high step-down ratio allows for a lower input current to the regulator, and is possible with devices such as the LMR14006, LMR16006, and LM46000 buck regulators. This higher ratio enables you to use a smaller value of C1, resulting in lower apparent power drawn from the mains. Applications such as smart-grid e-meters can benefit from this feature because of strict regulations on the maximum apparent power consumption; the typical maximum is limited to 8 VA.

Figure 2 shows the implementation with a half-wave cap-drop circuit. Since the half-wave circuit will disregard the negative cycle of the line voltage, this will result in a lower current delivered to the input of the wide VIN buck topology than in the full-wave circuit. Thus, for applications like battery charging, where a faster charge would require a relatively higher load current from the dc-dc regulator, the full-wave circuit is preferable.

The biggest advantage of these circuits is their size. In recent years, smart-grid e-meters have been shrinking in size, severely constraining available printed-circuit-board (PCB) space. To try and install a more conventional ac-dc circuit would not only increase the PCB area, but would also be quite complicated. This increase in board area would also directly relate to the cost. Cap-drop circuits are much more cost-effective, as the C1 capacitor is the only component required to be rated for ac voltages.

While these circuits are easy to configure, you should take utmost care to create a bench prototype and add an appropriate filtering and protection circuit to avoid potentially fatal injuries. The user must ensure that the intended application for this power supply, including its load, is completely isolated from any contact with grounded entities, including people, animals, and test equipment.

References:

Cost Effective Transformer-less Offline Supply for Light-Load Applications

About the Author

Akshay Mehta

Systems and Applications Engineer

Akshay Mehta is a systems and applications engineer with Texas Instruments’ SIMPLE SWITCHER product group, where he is responsible for product definition and development, bench validation, and customer support. Akshay received a master’s degree in electrical engineering from the University of Texas at Arlington.