Collaboration Broadens in the Electronic Design Community

This article is part of the Professional Advancement Series: Annual Salary Survey

Members can download this article in PDF format.

What you’ll learn:

- The need for collaborative software-development tools.

- The advantages of using collaborative tools in design and development.

Collaboration of design and development efforts in the creation of products, services, and solutions isn’t a new idea, but recent developments in both the tools available and the reasons to use them have permanently changed the design landscape. The ability for a team to work together remotely using telepresence tools and software has proven to be a game-changer in all aspects of the electronic products manufacturing industry.

According to MarketsandMarkets.com, the global enterprise collaboration market should grow from $47.2 billion in 2021 to $85.6 billion by 2026 (Fig. 1). This is being driven by the increased demand for real-time remote collaboration tools, cloud-based collaboration and design services, and project- and task-management solutions. Although these trends have been in existence for some time, the perfect storm of COVID-19 lockdowns forced a significant acceleration in application growth and market penetration.

This market report covers many development areas, but the electronic design aspect of the industry now touches anything that takes power to operate. In our latest Salary Survey, we had over 500 professionals working in the electronic design and development industry answer several questions about their jobs and the application spaces they serve. Of our survey group, over half were involved in Design & Development Engineering, with the second biggest block being made up of various levels of executive and operating engineering management.

This article will cover one of the many interesting aspects of the industry that was highlighted in the survey—in this case, remote design and development collaboration. Using collaborative software tools for design and development engineering isn’t a brand-new idea, it was trying to break out into the design mainstream for the last decade in one form or another. However, the telepresence “perfect storm” of COVID-19 forced the industry to adopt these next-generation team-based solutions, if only to enable their company to function in a quarantine environment.

The Impact of COVID-19 on Engineering

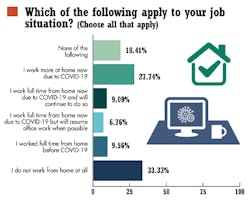

When we asked about their job situation, over 40% of the respondents answered that they work more from home because of COVID-19, with around 20% replying they will remain full-time home-office workers going forward (Fig. 2). (Half of those were already working from home prior to COVID-19.) An important thing to consider here is that the number of people working remotely has risen to the point where companies wishing to stay competitive must integrate remote team-interaction tools to enable efficient work integration.

The most important thing to consider, however, is now that these advanced tools are being used, they will not be put aside, even if everyone went back to the office. They offer significant force-multiplication advantages to a development team far beyond the convenience of working together remotely.

A team using collaborative design simulation software can outperform a design team working in the same room today. Not only can they work more seamlessly and intuitively, they now have a running documentation of everything being done.

The advantages of using modern design simulation tools are myriad, scalable, and reinforcing. Modern performance demands on electronic systems and the products they empower require optimized circuit and packaging. It’s far easier to exchange ideas and act upon them in a software-development environment that allows everyone to see the impact of everyone else’s input in real-time.

Moreover, these advanced design and development tools are exactly what’s needed to optimize products in today’s demanding regulatory environment as well. Considering the benefits of collaboration, documentation, flexibility, and remote collaboration, it’s obvious that these tools will continue to be used. Those who adopted these tools to address COVID-19 will continue to use them, and their competitors will adopt them as well to stay competitive. Even relatively basic advantages like saving the engineer who previously needed to keep track of the bill of materials in a project have huge implications.

How Collaboration Tools Empower Design

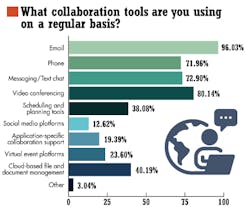

When asked about the kinds of collaboration tools they’re using, after e-mail, it turns out that video conferencing is the second most used, followed by the phone and texting (Fig. 3). With regard to more advanced tools, large blocks of respondents said they used scheduling and planning tools, cloud-based file and document management, application-specific collaboration support, and virtual event platforms. Even social media ranked as a collaboration solution that they used on a regular basis.

An interesting way to look at this is to see how the technologies being developed by our industry are now impacting how we work within it. Improved wireless and edge-based solutions empower remote hardware tools, for example, while improved messaging technology intended for general use also empowers inter-team communications. There’s a yin-yang relationship between the technology advances fomenting application development and those behind the creation of the next generation of tools used to apply them.

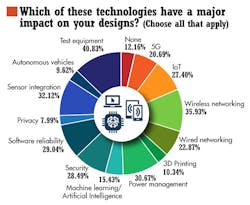

When we asked about some of the technologies that had a major impact on their designs, topping the list were wired and wireless networking technologies, sensor integration, AI and machine learning, and security (Fig. 4). Interestingly enough, test equipment and software reliability, both engineering-side tech, also were listed as major factors. This underscores the importance of certification, optimization, and verification needed in today’s design and development process.

On the practical side, the latest design simulation tools integrate electronic and mechanical design more seamlessly, enabling whole-product design optimization. Simulating various changes in components and attributes, engineers can explore complex electrical schematic iterations in real-time in collaboration with their team. This spurs on more effective buildouts of different layout alternatives and options with various results, comparing the various solutions against the application’s performance and regulatory requirements.

Historically, software and hardware design tools addressed electrical and mechanical functions separately, with separate software and hardware packages needed, and little or no interaction occurring between any of the stages. Not only do the latest solutions address the progress in component and systems complexity, they also merge electrical performance and mechanical design as integrated functions. For example, proper component simulation allows for proper thermal and stress analysis of the entire system based on the spacing of the components within the enclosure.

Comprehensive thermal analysis combined with a mechanical stress model showing system tension, flexion, and torsion enables a worst-case modeling scenario that proves out the packaging or exposes flaws in thermal management. Iterative design changes can then be made in real-time with input from the whole team based on the simulation results to improve the design.

Looking Forward

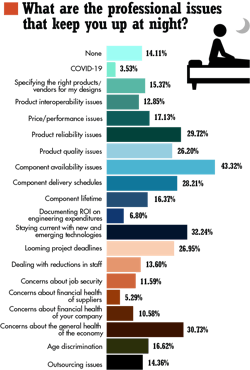

When we asked about what professional issues were on their minds, looming project deadlines and component availability issues lead the pack, followed closely by product-related performance, quality, and reliability issues (Fig. 5). A collaborative design environment linked to an intelligent manufacturing process and a comprehensive design-for-manufacture methodology can address all of these issues successfully.