Micro-Module Regulator Counters Conventional Wisdom on Output Noise

The messages of conventional wisdom and “rules of thumb” that were perhaps once true can take a long time to change. Consider the widely held view on step-down (buck) switching dc-dc regulators compared to all-analog low-dropout (LDO) regulators. After all, “everyone” knows that the former is far more efficient but has much higher noise than the latter. Furthermore, the difference is due to inherent architectural limitations; thus, there’s little that can be done about it other than filtering and more filtering.

That may have been true up to a few years ago, but it isn’t always the case. First, in the range of 0.5- to 1-A output, the LDO may be far less efficient than the switcher in the general sense. However, in some scenarios, such as when the duty cycle is low, the actual energy-usage difference may be small and even negligible.

Even more noteworthy is the change in switching-regulator noise performance, going far beyond just adding more output filtering (which brings a new set of issues related to dynamic performance). The LTM8080 from Analog Devices continues the advances as an extremely low-noise, dual-output dc-dc μModule regulator. It uses a combination of patented silicon, layout, and packaging innovations to achieve its specified performance to integrate the best of both switcher and LDO worlds without their downsides.

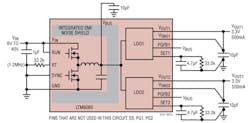

The LTM8080’s front-end is a high-efficiency synchronous Silent Switcher step-down regulator that’s followed by two separate, low-noise, LDOs (Fig. 1). The package includes the controllers, power switches, inductors, and support components. As an integrated solution comprised of a switcher and LDOs, it offers advantages of both while maintaining a small size and significantly reduced PCB layout sensitivity. To further suppress switching noise, the LTM8080’s packaging incorporates an EMI barrier wall or shield.

The LTM8080 operates from inputs ranging from 3.5 to 40 V; the dual outputs can bet set from 0 to 8 V at 500 mA each or combined for a single 1-A maximum. It targets digital loads that are susceptible to switching-regulator noise such as data converters, RF transmitters, FPGA I/O and clock, op amps, transceivers, and medical scanners.

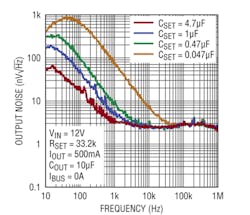

The result is exceptionally low noise values below1 µVRMS (10 Hz to 100 kHz), 2 nV/√Hz spot noise (at 10 kHz), and 80-dB PSRR (100 kHz) (Fig. 2).

Compared to discrete solutions without an EMI shield, the LTM8080 reduces output ripple voltage by up to 70% for a simplified and quiet design. It minimizes EMI emissions and enables the device to pass CISPR22 Class B and CISPR25 Class 5 without an input filter. In addition, the adjustable switching frequency (200 kHz to 2 MHz) and selectable operation modes minimize the risk of frequency interference for very-low-noise instrumentation and high-speed/high-precision signal-chain applications.

Furthermore, the LTM8080 has a built-in voltage tracking function that automatically sets VBUS to either 2.5 V nominal or 1 V higher than VOUT1, whichever is greater, to achieve superior noise performance and minimize power dissipation. It also has provision for external synchronization and offers a programmable “power good” indication.

The LTM8080, with a 28-page datasheet replete with tables, curves, and applications insight, is packaged in a thermally enhanced, compact (9 × 6.25 × 3.32 mm) overmolded ball-grid-array (BGA) package. The −40 to 125°C version is priced at $12.83 (1,000 pieces), while the wider range −55 to 125°C version costs $14.11. The devices are supported by the DC3701A demonstration circuit board (Fig. 3), complete with its own 10-page User Manual.

About the Author

Bill Schweber

Contributing Editor

Bill Schweber is an electronics engineer who has written three textbooks on electronic communications systems, as well as hundreds of technical articles, opinion columns, and product features. In past roles, he worked as a technical website manager for multiple topic-specific sites for EE Times, as well as both the Executive Editor and Analog Editor at EDN.

At Analog Devices Inc., Bill was in marketing communications (public relations). As a result, he has been on both sides of the technical PR function, presenting company products, stories, and messages to the media and also as the recipient of these.

Prior to the MarCom role at Analog, Bill was associate editor of their respected technical journal and worked in their product marketing and applications engineering groups. Before those roles, he was at Instron Corp., doing hands-on analog- and power-circuit design and systems integration for materials-testing machine controls.

Bill has an MSEE (Univ. of Mass) and BSEE (Columbia Univ.), is a Registered Professional Engineer, and holds an Advanced Class amateur radio license. He has also planned, written, and presented online courses on a variety of engineering topics, including MOSFET basics, ADC selection, and driving LEDs.