NI Software Brings the EV Battery Lab into the Future

While it’s not the only component that matters, the battery pack—and the cells crammed inside it—is the key to determining the total range, charging rate, acceleration, and lifespan of any electric vehicle (EV).

“Never before has one component had such far-reaching implications for the quality, safety, and performance of the final product while it itself is also undergoing a rapid pace of innovation and change,” said Elijah Kerry, NI’s head of EV battery test solutions, at its recent NI Connect event.

To help automakers and their suppliers stay a step ahead of the technological shifts happening in the world of EV batteries, NI recently launched its new Software-Defined Battery Lab solution.

The company said the new solution includes all of the core building blocks of a modern battery lab, giving companies the test and measurement hardware to build better batteries on a large scale. This will be essential to a future where electric cars, trucks, and other vehicles are affordable for the masses.

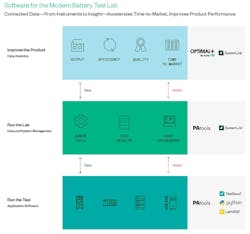

The solution is “software-defined” in the sense that it uses software tools to bind all of these components together in a single platform that can validate battery cells, modules, and packs while also handling data management and analysis. The flexibility and openness of the software allows for the faster development of custom test systems and reuse of code, said NI.

While designed specifically for battery validation labs, the new solution fits into its larger suite of testing capabilities. NI claims that its offerings can span the full lifespan of a battery from the test facility and production plant to its second life, to even recycling and re-manufacturing.

Testing at All Times

As major automakers rev up investment in EVs, they’re seeking out batteries that can store more energy per charge, charge more rapidly, and are less likely to explode than those currently in use.

But none of these innovations matter if the battery itself lacks automotive-grade quality, safety, and reliability—or they’re unable to be manufactured inexpensively in vast quantities, according to NI.

As a result, testing has become an even more critical part of the development cycle. It’s increasingly taking place at every phase of a battery’s lifecycle, not only at the end of production.

The goal, as NI pointed out, is to identify problems that can negatively impact safety, quality, and performance (including storage capacity and charging rates) closer to where they’re introduced.

But batteries present unique challenges when it comes testing, said Ben Wrightsman, CEO of the Battery Innovation Center (BIC), which works with automakers to help them scale up their battery production.

In contrast to a circuit board (PCB), a battery is defined not only by its electronic and mechanical properties, but also its chemistry, said Wrightsman. A battery’s condition changes based on its use over time and environment, giving each one a unique profile. He said the wide range of different storage capacities, form factors, footprint, and chemistries out there also add to the complexity.

Manufacturing a modern battery is no easy feat. The complete process can take several days to weeks—there are many junctures during production where even slight mistakes may cause defects, ranging from folds and wrinkles in the layers of raw material that comprise the anode and cathode to deformed tabs. These flaws can impact the inner workings of a battery, and thus, quality and yields.

Adding to the complexity, battery cells are bundled in modules to protect them from harsh conditions on the road before being loaded into high-voltage packs that can supply tens of thousands of watts.

The cell-module-pack arrangement creates many potential points of failure in the battery, said NI. If any one of the cells in a battery pack is damaged, the rest of the system becomes more likely to fail.

High-Power Hardware

The new software-connected battery lab builds on NI’s Battery Test System (BTS), which uses many of the same technologies to handle the difficulties of testing lithium-ion (Li-ion) and other types of batteries.

NI is using its regenerative battery cyclers to diagnose the internal operation of battery cells. Battery cyclers can subject the cell to a series of charge and discharge cycles and measure its capacity, efficiency, self-discharge rate, and other characteristics over time.

The solution works with NI’s latest battery cycler, the HPS-17000, which can inject up to 150 kW into the batteries being tested and draw it from them safely, with modes ranging from 400 to 1500 V. The system runs constant current/constant voltage (CC-CV), constant power (CP), constant resistance (CR), fast pulse, voltage and current ramp, and other tests to put the battery cell through its paces.

The other key building block of the battery lab is the measurement and control hardware. Based on NI’s CompactRIO, the real-time controller manages source and load to maintain continuous charge and discharge cycles. It also monitors the voltage, current, and other facets of the battery being tested in the environmental chamber, putting it through varying levels of vibration, moisture, strain, and temperature.

The real-time operating system inside the solution delivers deterministic operation. Precise timing and synchronization enable it to be scaled up to thousands of test channels or upgraded to do more advanced measurements.

BIC uses NI’s test and measurement systems to profile the impedance of battery cells in its labs, which is important as it impacts the suitability of the cell for EVs. While BIC has been using NI systems to run ac internal resistance (ACIR) tests on its batteries, the Center is upgrading to a more advanced set of measurements—called electrochemical impedance spectroscopy (EIS)—to extract even more insights.

Figuring out the impedance of the battery cell also provides insight into its overall quality and helps identify defects or other imperfections, as well as projecting the rate of aging or wear-out over its lifecycle.

Software Connections

For test development and execution, NI is rolling out battery test software powered by PATools from Kratzer Automation, which packages all of the plug-ins, device drivers, and other resources to run battery tests out-of-the-box.

But the software also enables easy modifications and extensions through NI’s LabVIEW platform and other common test software, saving time when reconfiguring tests for other batteries.

Designing and testing batteries creates vast amounts of data. To handle the deluge of data, the solution uses NI’s new SystemLink Enterprise platform, which will help users sort through data about a battery’s operation across the test lab to the production plant and spot areas—such as the chemistry or form factor of the cell or the architecture of the module or pack— ripe for improvement.

Co-developed with GM, NI said SystemLink Enterprise plays a wide range of different roles in the lab, including managing and monitoring all test and measurement systems and other systems equipment in the facility to help maximize productivity and uptime.

The one of the more unique features of the SystemLink platform is that it can feed any format of data from any test and measurement system—at any point on the lifecycle of the battery—into a central location, contextualize it, and make sense of it. The data can also be displayed on custom dashboards.

Flexibility in Focus

Northvolt is using NI’s lab to help amass vast amounts of data from testing and validating its battery cells. This will give engineers insights into the performance of its devices as it aims to scale up production to the levels required by its customers, which include the likes of BMW, Volvo, and VW.

To help build better batteries at scale, the company is keen to gather data throughout a battery’s lifecycle—from its research labs and test facilities to production lines and even from the fleets of battery packs carrying its cells out on the road.

Northvolt hopes to harness the insights to improve its development process. It also intends to update and upgrade the software inside its batteries wirelessly, in consultation with customers.

For Northvolt, one of the perks of NI’s software-connected battery lab is that it’s open and flexible, whereby companies can quickly reconfigure and update it to meet constantly changing test needs.

Unlike fragmented or closed battery test systems, NI’s solution allows for the integration of third-party hardware, preventing lock-in with a single vendor and enabling the reuse of existing test equipment.

“Owning our test strategy enables us to quickly implement the features we need so we’re not held back by technology limitations,” said Henrik Rudelius, head of battery validation and simulation at Northvolt. “That openness accelerates the product know-how of our battery systems.”

About the Author

James Morra

Senior Editor

James Morra is the senior editor for Electronic Design, covering the semiconductor industry and new technology trends, with a focus on power electronics and power management. He also reports on the business behind electrical engineering, including the electronics supply chain. He joined Electronic Design in 2015 and is based in Chicago, Illinois.