According to market research firm IHS, the energy storage market is set to “explode” to an annual installation size of 6 GW in 2017, exceeding 40 GW by 2022. Such forecasts reveal a huge jump from an initial base of only 0.34 GW installed in 2012 and 2013. Here is a list of seven energy storage disruptors that are innovating and changing the industry as we know it:

ViZn Energy. Founded in 2009, this firm is using an emerging technology called a zinc-iron flow battery. That battery runs on a safe chemistry that is non-toxic, non-flammable, and non-explosive. In addition, flow battery systems do not require cooling systems. The company just announced a large-scale storage microgrid project that will be built in Nicaragua at Rancho Santana Resort (Fig. 1). There, the ViZn (four-hour) flow batteries will be combined with an 800-kW-peak solar photovoltaic (PV) system. It will be interesting to observe whether this technology will significantly attract more investments and carry more projects.

1. Rancho Santana is a world-class resort and residential community covering 2,700 acres on the Pacific Coast of Nicaragua. (Courtesy of Rancho Santana)

Nissan and Eaton. These companies provide a sustainable energy storage solution for homeowners known as the Nissan XStorage unit (Fig. 2). These units provide a second life for Nissan’s electric vehicle (EV) batteries. The XStorage units can draw energy from the sun or from the grid (a smartphone app will allow consumers to manually switch between energy sources).

2. The battery is used as a home storage unit, which you can control—deciding how and when the energy is used. (Courtesy of Nissan)

The units come with solar panel inverters that are already integrated for use with renewable energy sources, such as existing solar panels. They are available in different sizes: 4.2 kWh (second life batteries), 6 kWh (new or used batteries), and 9.6 kWh (new batteries). This should be a good option for homeowners who are allowed and able to sell energy back to the grid. They also could be use as energy back-up in case of a blackout. Time will tell if reusing batteries for stationary energy storage applications is profitable and if this sustainable solution will eliminate the need of battery recycling.

Tesvolt and Samsung. Tesvolt teamed up with Korean cell manufacturer Samsung SDI on a new storage system. It uses Samsung SDI’s new prismatic lithium cells, which BMW recently introduced into its electric cars. The storage system (Fig. 3) can operate from 48V to 1,000V for stationary commercial and industrial applications.

3. Every battery module has its own Active Battery Optimizer (ABO), which can be separated from the module in a few easy steps for servicing or other tasks. (Courtesy of Tesvolt)

The companies claim that the storage system can complete around 6,000 full charge cycles with a depth discharge of 100%, which means that the entire battery capacity can be used and controlled by the Active BAT Optimizer (battery management system). Battery modules can be exchanged at any point. Storage capacity can also be expanded years down the line, which is a feature that many commercially available lithium storage systems can only exploit during the first year.

RES and NREL. Renewable Energy Systems (RES) undertakes projects that integrate energy storage units with renewable sources and the grid. The RESolve system has been selected for the 1-MW/1-MWh energy storage test project at the Energy Department’s National Renewable Energy Laboratory (NREL) National Wind Technology Center (NWTC; Fig. 4). Energy storage projects like this help the industry better understand how renewable resources, such as wind energy, impact the grid.

4. The National Renewable Energy Laboratory (NREL) campus is located in Golden, Colo. (Courtesy of NREL)

It also shows how storage units can successfully be integrated to optimize the grid. When this project is completed next month, NREL staff at the facility’s National Wind Technology Centre (NWTC) will utilize the demonstrated applications of RESolve to test a variety of modes. These will range from frequency regulation and renewable energy integration to more advanced modes, like “black start” and seamless grid-to-island transition.

Tesla. The electric car powerhouse is increasingly adding energy storage solutions to its portfolio. The Powerpack is one of the grid-scale energy storage products designed by Tesla. In January, the company announced the multi-phase construction of its Gigafactory in Sparks, Nev. (Fig. 5). By 2018, the Gigafactory will produce 35 GWh/year of lithium-ion battery cells—nearly as much as the rest of the entire world’s battery production combined.

5. The name “Gigafactory” comes from the factory’s planned annual battery production capacity of 35 gigawatt-hours (GWh). (Courtesy of Tesla)

The Gigafactory is taking advantage of mass production to reduce the price of batteries, creating American manufacturing jobs in the process. The company also is planning to build three new Gigafactories, including a production facility for photovoltatic cells in Buffalo, N.Y. These expansion plans underscore the company’s commitment to increase its use of renewable energy and foster a clean energy ecosystem.

Argonne National Laboratory. One of the objectives of Argonne's battery research program is to develop more robust, safer, and higher-energy-density lithium-ion batteries. At the same time, the lab plans to use its fundamental science capabilities to develop storage materials that dramatically increase storage capacity and power densities.

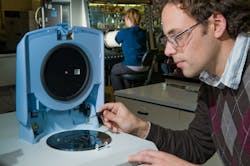

Argonne (Fig. 6) has a portfolio of more than 125 patented advanced cathode, anode, electrolyte, and additive components for lithium-ion, llithium-air, lithium-sulfur, sodium-ion, and flow batteries. For example, the battery chemistry of the Chevy Volt was based in part on a breakthrough pioneered by scientists at the U.S. Department of Energy’s Argonne National Laboratory. Through research and development, they continue to push batteries so they may reach their full potential for power density, duration, and cycle.

6. Argonne battery researcher Kevin Gallagher places a charged lithium-ion battery cathode into a differential scanning calorimeter, which helps scientists evaluate how the material responds to changes in temperature. (Courtesy of Argonne National Laboratory)

Sonnen. Although this residential energy storage company is headquartered in Wildpoldsried, Germany, Sonnen is planning to invest in a North American Innovation Center. That center will combine the company’s U.S. manufacturing operations and product research and development in a single facility. The sonnen InnovationHub is expected to begin production in the second quarter of 2017.

It will enable the company to innovate and produce their sonnenBatterie systems (Fig. 7) for the U.S. market in one central location (Atlanta). The sonnenBatteries with backup capability uses lithium-iron phosphate (LIFePO4), and they scale from 4 kWh to 16 kWh. Sonnen’s goal is to offer solution to American homeowners and commercial businesses interested in achieving energy independence.

7. The sonnenBatterie has a lifespan of 10,000 charge cycles. (Courtesy of Sonnen)

Looking at this list, we can expect many innovations in two main energy storage products: batteries for electric cars and stationary storage (batteries for homes, businesses, and the grid). Having a smart grid and taking advantage of renewable energy sources makes little sense without the integration of an energy storage unit. By combining these systems and giving us the ability to store and share energy, energy storage has the potential to change our everyday lives.

About the Author

Maria Guerra

Power/Analog Editor

Maria Guerra is the Power/Analog Editor for Electronic Design. She is an Electrical Engineer with an MSEE from NYU Tandon School of Engineering. She has a very solid engineering background and extensive experience with technical documentation and writing. Before joining Electronic Design, she was an Electrical Engineer for Kellogg, Brown & Root Ltd (London. U.K.). During her years in the Oil and Gas Industry she was involved in a range of projects for both offshore and onshore designs. Her technical and soft skills bring a practical, hands-on approach to the Electronic Design team.