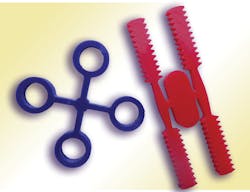

SiTimes offers two kinds of silicon resonators (see the figure).One is a double-cantilever-beam low-power structure used for 32-kHz clocks for timekeeping applications such as watches. The other is a quadruple-ring structure used for 48-MHz data-clocking chips.

Essentially, the two cantilever elements in the 32-kHz devices behave like a pair of coupled vibrating beams, back-to-back. The rings have a more complex vibration mode, which can be described as something akin to the way the mouth of a bell vibrates.

In both cases, the devices were built with multiple resonators to increase the signal-to-noise ratio of the raw input to the clock chip’s internal electronics. The multiple resonators also were center-anchored to reduce power consumption and to minimize the effects of external shock and vibration by reducing the coupling.

The core of the analog portion of SiTimes’ clock devices is a fractional-N phase-locked loop (PLL), in which the reference frequency is divided by an integer multiple before it is input to the phase comparator. This allows the synthesis of frequencies that are N/M times the reference frequency, where M would be the multiplication factor of a conventional PLL. The analog electronics inside the clock devices also filter out shock and vibration artifacts, along with their basic function of driving the resonators.

Getting the internal resonators just right is non-trivial. Companies must develop their own simulation software to predict and analyze the behavior of new designs across a range of operating parameters. It’s classic mechanical engineering, done at a nano scale. (SiTime’s actual die size is 0.4 by 0.4 mm.)

At the scale of these structures, silicon tends to become a perfectly elastic material. In addition, due to the scale, the maximum deformation forces that a resonator structure sees are orders of magnitude less than the stress failure point of the material. That’s a useful point in selling against quartz crystal clock devices, which have decades of reliability data to support their claims of robustness.

On the analog side, most of SiTime’s catalog is based on 0.18-µm CMOS. The company uses TSMC as a foundry. On the MEMS side, SiTime uses TowerJazz and Bosch, which has been connected to SiTime since its founding.

About the Author

Don Tuite

Don Tuite (retired) writes about Analog and Power issues for Electronic Design’s magazine and website. He has a BSEE and an M.S in Technical Communication, and has worked for companies in aerospace, broadcasting, test equipment, semiconductors, publishing, and media relations, focusing on developing insights that link technology, business, and communications. Don is also a ham radio operator (NR7X), private pilot, and motorcycle rider, and he’s not half bad on the 5-string banjo.