Download this article in PDF format.

Microelectromechanical-systems (MEMS) technology uses micro fabrication techniques to combine microelectronics capabilities with the mechanical properties of microsensors. Increasingly, MEMS gyroscopes and accelerometers are used in a large number of devices for both consumer and industrial applications.

Active suspensions, for example, require four extremely stable and accurate sensors mounted on the wheels in order to achieve a greater degree of ride quality and car handling, thus allowing for better traction and control. Another application is to prevent passengers on the front seat from being thrown out of the passenger compartment in case of an accident.

The benefits of these MEMS approaches include high efficiency, small size, and low cost. Automobile MEMS sensors play a key role, solving safety challenges in an extremely accurate and stable design. In fact, electronic safety systems based on MEMS technology can ensure compliance with functional safety standards, enabling designers to more efficiently achieve their goals. Demand is stronger than ever for enhanced safety and security in the automotive industry, which is propelling growth and development in the MEMS market.

MEMS accelerometers and gyroscopes both are benefiting from this growth. Accelerometers measure accelerations in one, two, or three orthogonal axes. They’re typically used to calculate inclination or orientation with respect to gravity acceleration, as well as to measure vibrations and shocks. To select the right accelerometer for particular application, designers must consider different project variables, including sensor structure, resonance, reliability, stability, bandwidth, and energy consumption, together with cost.

In contrast, MEMS gyroscopes provide a simple way to measure angular velocity (or rotation motion) in easy-to-install packages on the printed-circuit board (PCB). They’re a popular choice for feedback systems as a sensitive element for motion control.

More on MEMS Accelerometers

Most accelerometer sensors are of the silicon variety. These devices generally break down into two fundamental types—they’re based on either a capacitive or thermal approach.

Depending on the application, use of a MEMS thermal accelerometer can be advantageous for a number of reasons. For example, the capacitive approach may be more suitable for detecting a car accident and/or activating the airbag. In contrast, the thermal approach is best suited for electronic stability control (ESC), as it’s based on the principle of the convection of heated gas molecules inside a sealed cavity.

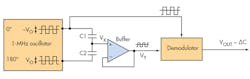

1. Shown is an electrical diagram for measuring variations in capacity from a MEMS sensor. Detection is based on capacity variation when the geometry of a capacitor is about to change.

Through very accurate sensors, it’s possible to detect variations in the temperature profile resulting from small variations of acceleration (or inclination). Capacitive MEMS, on the other hand, exploit the piezoelectric effect through microscopic crystalline structures urged by accelerating forces. This, in turn, causes electrical stress. They are intrinsically broadband transducers (> 5 kHz), with a mechanical resonance frequency of near 2 kHz for low g devices. A typical way to detect temp-profile variations is to measure the variation of capacities, where the capacitors can operate both as sensors and actuators (Fig. 1).

Capacitive accelerometers require a two-die solution (one for the sensor element and the other for the application-specific integrated circuit, or ASIC) to measure inclination in high-vibration environments. In most cases, the sensor element requires a much larger geometry than the ASIC. For its part, a MEMS thermal sensor integrates the sensor and electronics into a single monolithic IC, which results in a much smaller device and thus simplifies the assembly process.

MEMS Gyroscopes

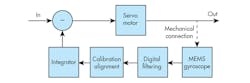

Most available MEMS gyroscopes are based on a diapason configuration with two masses, which oscillate continuously in opposite directions. When an angular force is applied, the Coriolis’s strength on each mass also acts in opposite directions. The resulting variation in capacity is proportional to the angular velocity (Ω). That velocity is converted to an output voltage for analog or digital gyroscopes (Fig. 2).

In terms of noise, MEMS gyroscopes contribute to angular velocity. This intrinsic noise represents the variation of the gyro’s output signal when it’s in a state of static inertia (i.e., without rotation) and in conditions of environmental immunity (or without vibrations or bumps).

2. MEMS gyroscopes use the Coriolis effect to measure angular velocity. When a mass (m) is moving in the direction of V and an angular rotation Ω is applied, the mass will experience a force in the direction of the arrow (FCORIOLOS) due to Coriolis's strength.

The most common parameters for describing such noise behavior are rate noise density (RND) and angular random walk (ARW). The RND factor typically uses a unit of degrees/sec /√Hz and provides a simple mode to predict total noise based on the gyroscope frequency response. The ARW factor, on the other hand, typically uses grading units/√hour , and is often more useful when analyzing the impact of noise on angle estimation for specific time periods.

What’s Next?

As the automotive industry continues to undergo a massive transformation, new features like advanced safety and driver-assistance systems continue to evolve. The various sensors already available, such as pressure and temperature, will still be used in vehicles. Yet other types of sensors will certainly be implemented in autonomous driving to support safety functions.

In addition, advances in science and engineering will lead to new materials and processing methods. They will enable the design and manufacturing of film for next-generation MEMS technologies and sensors targeted at automobile applications like advanced driver-assistance systems (ADAS).

Inside the cabin, for example, automotive companies are designing MEMS microphone solutions to offer new voice-control functions with noise-to-noise ratios in the range of 60 to 70 dB. Such microphones offer a high signal-to-noise ratio (SNR) and good sensitivity with a surface-mount assembly processes. Moreover, they offer less variation in sensitivity over temperature, with significant advantages in terms of performance, reliability, and manufacturability for a multitude of safety applications in the automotive industry.

In addition, a gyroscope can be used to activate the electronic-stability-control (ESC) braking system to prevent accidents when the car is, for example, traveling along a narrow curve (Fig. 3). A gyroscope also can be used to activate an airbag when there’s a tilting condition or frontal accident. In machines, including those of the automotive variety, it can be used to measure orientation to keep the direction of movement on a digital map when the GPS signal is lost (dead-reckoning systems).

3. Within feedback systems, the MEMS sensor performs the feedback task and, therefore, the control response is associated.

Noise vs. Motion Control

Clearly, MEMS gyroscopes and accelerometers already help to make automobiles more secure—their massive presence in vehicle control systems significantly enhances driving stability. A MEMS device also forms the core of a system that in most cases requires noise filtering, adaptive learning algorithms, and the ability to reset any imbalance of the effects due to temperature variations and vibrations.

Keep in mind, though, that the noise of MEMS systems can have a direct influence on the key performance criteria in motion-control systems. Thus, it should be carefully considered in the design process.

Also keep in mind that a new MEMS market is emerging: nanoelectromechanical systems (NEMS). Due to their sensitivity, these nanometric devices are able to get very small sensors to detect stress and vibration at the atomic level.

Nanotechnologies promise to improve the performance of existing automotive technologies, improving engine efficiency and fuel consumption. These devices increase the computational ability of microelectronics and mechanics with sensing and control capabilities, providing a high level of functional integration and low-power operation.