Download this article in .PDF format

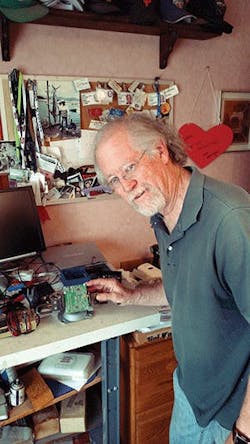

Dale O'Harra has been designing for PCBs since receiving a BSEE from Oregon State University in the early 1970s. He's designed for companies as big as Hughes Aircraft and for his own company to develop intellectual property for licensing and develop products for sale. His current project is a vector analyzer.

When it comes to printed-circuit boards (PCBs) and assembly, any engineer who works for a large company has plenty of internal resources to call upon. It can be different for an engineer at a startup—or one who hopes to sell the intellectual property of a product under development. To find out more about what it’s like to “work without a net,” I turned to Dale O’Harra, who I last wrote about back in 2006 (see “Antenna-Analyzer Designer Bypasses the Business Bull”).

Dale is, in fact, working on the latest version of that analyzer, but he also has lidar and infrared imaging projects underway on his workbench. All use state-of-the-art technologies that were out of reach for practical projects nine years ago.

When I spoke with Dale, my first surprise was how slowly board-making and assembly technology had evolved compared to the underlying semiconductor technology, at least for his kinds of projects. The reason for that is, once component packaging shrinks beyond a certain scale when working at his level of product development, hand assembly is out of the question. What’s interesting is how far down in scale it’s possible to go if one is clever about using solder wick and dental tools. (In the earlier article, I pointed out that Dale is acutely near-sighted. His eyeglass lenses are ground to a correction of six diopters, so when he needs to see something really tiny, he just takes off his glasses and squints. Engineers handicapped with near-normal vision could always use a jeweler’s loupe, though.)

I started off the interview by asking Dale to describe his relationship with PCBs and new products over the years:

Dale: Back when I first started, which would have been in the late '70s, or early '80s, I'd hand-draw the schematics, and then, preparing the artwork for creating the PCB would be a tape-up job. I would tape them up large and then photo-reduce them down. The circuit-board fabricators would build me the board from those films.

Then there was a photo house I used. I would take my artwork down to them, they'd do the photographs for it, and I’d take them down to Bay Area Circuits for production.

Later, when I was doing a lot of prototypes, I'd use wire wrap, working off the schematic. I'd just mark up the schematic as I put the wires on, wire-wrapping them to DIP sockets on the board. Then, when I worked for a company that had a little more money, we did schematic capture on the computer using OrCAD. From that, we again did tape-ups from the schematics.

After OrCAD, we went to Protel, which was an inexpensive board-layout program. It was an inexpensive one. The drawbacks to all that were we couldn’t calculate fringing, or any RF characteristics.

Frankly, I hand-routed most of the stuff anyway, because the auto routers in those days weren't very good. Some time ago, I started using EAGLE, from Cadsoft for schematic capture. It includes an auto router, and does board layout. That led to me using PCB Fab Express, because I could just email them the outputs of the EAGLE software, and a week later, the boards would show up at the door.

Boards Meet Components

As Dale explained to me last time, he has his own techniques for assembling components to PCBs. In fact, it’s almost guaranteed that there will be problems with the first iteration.

Dale: As far as stuffing the boards, I just hand-build them myself here, because I would never get them done perfectly the first time. There are usually little modifications needed.

Don: You’re referring to “white wires” and jumpers...”

Dale: Yes, but there are more subtle things. I don’t always remember to position surface- mount parts near the edge of the board. There are all kinds of little tricks.

Don: In terms of component sizes, what kind of scale are you working with? How do you solder?

Dale: In terms of pad pitch, I typically use 1206 or 805. I don't go down any tighter than that; that's as good as my eyes can handle.

Actually, you will find smaller pitches; I'm forced into it in some cases. Not ball grid arrays, of course. But in my latest antenna analyzer design, I used parts just incredibly small, so small you can't put the soldering iron on an individual lead.”

Don: What do you do then?

Dale: You get pretty good at soldering them en masse, and then wiping excess solder away so they stick.

Don: Wait. Can you describe that process a little more in depth, a little more detail?

Dale: Sure! Sure. Yeah. You can take... you know solder wick? If it's a very small component, you start by soldering down one corner. Then you use your tweezers and wiggle the component around until you can tack down the diagonal opposite corner with more solder. After that, you look at it real good under a microscope, carefully, and if it's really lined up, and if the pads are really aligned, (which they are about one out of four times; that's why you only do those diagonally opposite corners ) you can keep adjusting their positioning. When you finally get it adjusted right, you take the solder and flood each of the sides of the component with it.

So now, you've got your leads soldered, but they’re all shorted. Then you simply take solder wick, wet it thoroughly with solder, and hold it in place while running the soldering iron all around the periphery of the component so that the solder wicks most of the solder off the pads. You finish up with the component’s pads all stuck to the board where they should be.

The best thing to do is build the solder wick into a U shape, so you’re able to hold it up both against the package and the circuit board. Then you use the soldering tip to heat the U while you slide it up and away. That way, the heat is transferred to the wick and the wick pulls the solder up out of the gaps between the pads on the board and the component. Meanwhile, the soldered-down pads on the other side hold the component in place on the board. It’s a way of using surface tension to clean up one side of the component first, and then the other.”

Don: Does that always work?

Dale: There are other components, like the Bluetooth device that I'm using on the new antenna analyzer. You're not really supposed to be able to solder to it externally, so the pads only come out flat to the edge of the substrate.

In a case like that, I wet all of the pads on the circuit board, set the component on the board, and then try to slide the soldering-iron tip around its edges, so that it pulls solder up from the trace onto the wetted pads on the part. That’s a little tricky. You have to do that a bunch of times before you get it right.”

Don: How is this for reliability?

Dale: It’s not so good for long-term reliability, but it’s satisfactory for an engineering prototype.

Don: For a prototype? For any kind of volume, do you go to an assembly house?

Dale: Yes. If I'm doing 10 of them, then I'm not going to do it that way, because I'm not that fast. In the higher production volumes, as with the antenna analyzers, I have it done in China. Although I suspect, even there, it's still done by hand, not with pick-and-place robots, because they couldn’t pay for them given my kinds of production volumes.