Tell us a bit about your latest platform (see “Hands-on a SPLat HMI430 Controller”).

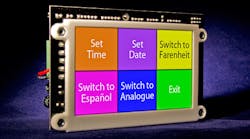

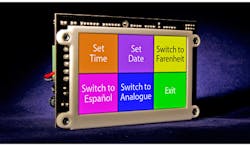

Stonier-Gibson: The HMI430 (Fig. 1) is our first embedded controller and color touchscreen combo product released for general sale. We have previously done a number of touchscreen designs as custom products. That allowed us to gain a good understanding of the issues and use cases and tailor a very cost-effective package for our target markets.

Wong: What are the target markets?

Stonier-Gibson: We specialize in embedded controls for OEMs. Usually these are small- and medium-sized companies that make some kind of business-to-business product. Their expertise is in the product they make, not electronic controls. So they need a control solution they can implement without in-depth knowledge of electronics or programming. The HMI430 should be particularly suitable for OEMs who are feeling under pressure from what we call the iEffect—the increasing expectation that everything have a touchscreen.

Wong: What features of the HMI430 are unique?

Stonier-Gibson: Historically, the HMI or user-interface function has been regarded as separate to the machine control function, and has to be programmed separately, using separate tools. We pioneered the idea of a user-programmable controller with an integral user interface back in 1998, so to us, an all-in-one design is the natural order. In the HMI430, the control program and the user-interface program are one and the same. It is so much simpler to maintain a single program than to keep a control program plus an HMI program in sync. Not to mention it’s easier for an end-user to install updates.

This file type includes high resolution graphics and schematics when applicable.

Wong: By end user you mean...?

Stonier-Gibson: We have a customer who makes a machine, say the fellow in New Zealand developing a beer-bottling machine with the HMI430 — a real case, by the way. He, in turn, has a customer in say, oh, France, who runs a microbrewery. That guy is the end user. We have to consider not only our customer’s experience, but also that end user’s experience. So we, for example, want to make it easy for our customer to issue his program updates to the end user and have him install them. Hence a feature like a single drag and drop that includes all the binaries, plus support resources such as images and fonts, can make a huge difference.

But talking of drag and drop, you can also go the other way and get a screen capture off the HMI430 by dragging and dropping a particular file into your computer. That’s a feature I asked the development team for specifically to assist our customers in documenting their products. I’ve done enough manuals in my time to appreciate the significance of that one! Come to think of it, the guy in France could even use it to report any problems he’s having!

Wong: When could I get one?

Stonier-Gibson: We have sample quantities on the shelf at present, and a larger batch in production. There should be plenty of product available before anyone has completed a design-in.

Wong: Can you name any notable customers for your existing products?

Stonier-Gibson: Well, one of our first big customers was Carrier. We supplied the controls for the large rooftop heat pumps they made for many years in Australia and exported all over the world—to places ranging from Saudi Arabia to, remarkably, Siberia. But we also make the controls for Coolerado in Denver, who makes the world’s most efficient air conditioner. It uses about 15% of the power of a conventional compressor machine, and is popular in data centers and big box stores. It uses an optimizing control algorithm that’s literally driven by a bunch of mathematical equations, executed by a custom SPLat controller.

Outside of air conditioning, we have companies like ANKOM in New York, who make instruments for analyzing fat and fiber content of food. Most of their instruments use SPLat controllers. Then we have HydroCo, whose wellness equipment, such as hydrotherapy tubs, are used in upmarket day spas, including on the Queen Mary 2 (Fig. 2). They have used our controls exclusively since the mid-1980s. You can even find our controls in security turnstiles in — let’s just say — “a famous mansion in Washington” and in the New York Stock Exchange. These all contain SPLat controllers.

Wong: What makes the SPLat system special?

Stonier-Gibson: It was designed from get-go to be accessible to people who are expert at whatever their product does, but not necessarily in embedded controls. That meant we had to provide a platform that was easy to learn and forgiving of mistakes. When we started, the affordable single-chip processors had tiny memories, so it had to be memory-efficient. The answer was to use a virtual-machine (VM) architecture, which not only results in amazingly compact programs, but also provides opportunities to catch runtime errors and guarantee a known-error behavior.

Wong: That sounds rather unconventional. What led you down that path?

Stonier-Gibson: Back in 1995, we were a typical small suburban “gun for hire,” project-oriented electronics company. We were achieving some solid successes, like making timing systems and scoreboards for the Swiss timing company Omega. But we started to realize that much more time and effort was going into the firmware rather than the hardware, and the time spent programming was limiting the number of projects we could take on. That’s when we hit on the idea of making a general-purpose hardware platform that our customers could program themselves.

We had also just discovered the Internet and the World Wide Web, and saw that as a marketing opportunity. So we designed a programmable-controller board and a controls-optimized programming language that was safe and easy to learn. Then we wrote an IDE with a number of built-in learning aids, and we hid away as much housekeeping as possible, like hardware initialization and contact debounce, under the hood. The IDE included a full simulator, the idea being to give away the IDE for free, let people discover how easy it was, then come back and buy our boards. We have learned a lot more about marketing since then!

Wong: What do you mean by a “safe” language?

Stonier-Gibson: At the simplest level, take something like contact debounce. To someone without appropriate experience, contact bounce in a limit switch could cause the most baffling bugs. That’s a typical trap for young players. So we made our VM do the debounce automatically. When we added an on-board buttons-and-LEDs user interface in 1998, we added an instruction to catch and latch an off-to-on transition on the button inputs, so a program could easily detect single button presses. Little things like that are more than simple conveniences, they can make the difference between success and failure, and certainly shorten time to market.

But the big one, which came when microcontroller memories were big enough to handle the extra under-the-hood firmware, is our integral multitasking system, which we call MultiTrack. This allows up to 64 concurrent tasks in the HMI430 in a cooperative multitasking system. Many would regard a cooperative system as primitive and low performance. Maybe so, but the huge advantage is that it is safe from the problems of preemptive, priority-based systems such as resource locking and priority inversions. That allows our customers to implement sophisticated multitasking controls safely, even with limited experience in such matters. It’s a performance versus comfort tradeoff, but one we are very comfortable with.

Wong: So do all of your customers do their own programming and integration?

Stonier-Gibson: No, not at all. It goes about 50/50, I guess. Some customers are only too happy to have us do the programming for them. We have developed a special skill at extracting from people what they need the program to do. Also, we frequently and proactively get involved in suggesting ideas for their machines, maybe some way they wouldn’t have thought of to make their product better or cheaper by making the program smarter.

As an example, HydroCo, a local company I mentioned earlier, had us integrate a prototype HMI430 into their latest hydrotherapy tub. It is actually connected to an existing custom controller we make for them, with water-level sensors and special ball valve and motor drivers. We write all of HydroCo’s programs, and have done so for 30 years. Other customers are quite OK with doing their own programming, maybe just calling us for a bit of advice from time to time. The important principle we always keep in mind is that unless our customer’s product is a success in the market, we don’t get to sell them controllers. So it pays to assist them as best we can.

Wong: Getting back to the HMI430, what kind of expansion options does it have?

Stonier-Gibson: Over the years, we have built up quite an impressive range of I/O expanders and special function add-on boards. They range from plain digital I/O up to a high-grade isolated pH front-end and an Internet connectivity module. With the HMI430, we are introducing a new range of digital I/O expanders that connect via RS-485, and are actually SPLat controllers in their own right. That is in addition to most of our older controllers also being able to network with the HMI430.

Wong: You mentioned custom controls. Could you please elaborate.

Stonier-Gibson: Yes, much of what we do is actually custom embedded controls. However, in 99% of cases, they are still SPLat controllers, using the SPLat VM and all of the support tools. That means that when we design a custom controller, we can hit the ground running. The only new design work is any bits of unique circuitry that may be required. Everything else is pretty much boilerplate stuff, so the risk factor is negligible compared to starting from scratch. We routinely turn around a custom hardware design in four to six weeks, and if it was well specified, it generally won’t need a second spin. We always include our standard expansion bus, so the custom controller can immediately tap into our existing ecosystem of expansion boards.

This file type includes high resolution graphics and schematics when applicable.

Wong: I noticed you don’t put the usual technical specs like processor speed and memory in your advertisements and documentation. Why is this?

Stonier-Gibson: Well, we see our customers as people who need controls in their product, to make themselves more competitive, not people who want fancy specifications. These are serious product developers and entrepreneurial types. They are after results, a product that works. And frankly, the vast majority of products we get involved in are slow—public space barbecues and greenhouses don’t need gigahertz or megabytes. They need 24/7/365 reliability at an affordable price.

Wong: So you’ve been making these controllers for what, 19 years. What changes have you observed in the technology in that time?

Stonier-Gibson: Our first SPLat controller used an 8-bit processor with 8K of OTP PROM and 500 bytes of RAM. We had to use an external serial EEPROM for the user program, so it was really quite slow. The HMI430 uses an ARM Cortex-M4 with 512 kB of flash and 96 kB of RAM, plus hardware floating point. By my estimation, we are getting about 500 to 1000 times more bang per buck today than in 1995. That allows us to do very much more in our VM and still have much faster application execution.