DDS Looms as the Industrial Internet of Things Middleware Solution

Smart machines will change the world economy more than anything since the industrial revolution. These smart machines will combine to form an “Industrial Internet of Things (IIoT)” that connects them into truly intelligent distributed systems. The Internet changed the way people access distributed information. About 1 billion nodes populated the Internet, including laptops, computers, and servers. Then the mobile revolution came along and introduced about 5 billion smartphones.

However, these pale in comparison to the next wave of connectivity. The “Internet of Things” (IoT) promises to connect up to 50 billion devices in a short five years. That means that the IoT will dwarf the Internet by a factor of 50, and the mobile revolution by a factor of 10. The profundity of that statement is difficult to overstate. The IoT will revolutionize everything from how you live to how the electric grid generates power.

This file type includes high resolution graphics and schematics when applicable.

Some IoT applications are still about people, such as wearable smart glasses and smart home thermostats. But the vast new opportunity is about infrastructure in industry, or the Industrial Internet of Things (IIoT). This article focuses on that opportunity.

What is the Industrial Internet of Things?

Industry leaders are all positioning around the IoT and the IIoT:

• Cisco calls it the “Internet of Everything…the latest wave of the Internet—connecting physical objects…to provide better safety, comfort, and efficiency.”

• IBM says, “the Internet of Things…is a completely new world-wide web, one comprised of the messages that digitally empowered devices would send to one another. It is the same Internet, but not the same Web.”

• GE coined the term, “Industrial Internet.” Their vision is the “…convergence of machine and intelligent data…to create brilliant machines.”

Cisco’s “everything” position is broad and absolutely true. But, by focusing on everything, it doesn’t capture the nature of the change to industry. IBM correctly points out that while the foundational infrastructure of the Internet hasn’t changed, the IoT isn’t a human-controlled web. The IIoT requires new protocols that marshal the information needed by devices in the way they need them. But, it talks about how to implement the change, not the change itself.

GE’s vision beautifully captures the real change—brilliant machines. The current Internet is about people. The IIoT is about smart machines. More specifically, the IIoT is about the futuristic systems that will drive the physical world.

Just as the Industrial Revolution was about harnessing engines and electricity to enable new classes of physical infrastructure, the IIoT is about harnessing the information flow that will enable new classes of physical machines. And the most profound are big-iron infrastructure. Smart freeways, distributed power generation, connected hospitals, and, yes, autonomous flying cars with intelligent air traffic control are the future. This huge infrastructural transformation will dominate the next 100 years of technical evolution. Technologies don’t get more profound than that.

Recently, the above companies, along with Intel and AT&T, created an organization called the “Industrial Internet Consortium” (IIC). The IIC will be managed by the Object Management Group (OMG), the world’s largest systems software standards organization. The OMG is the same standards group that specifies system languages like UML. Less than two months after its founding by the big five, the IIC has about 50 members. Placing the IIC inside the OMG is a brilliant move. The IIoT needs a get-your-hands-dirty, drive-a-specification-to-closing, concrete-standards driver. And it needs an organization with real systems perspective. The OMG is exactly that.

The OMG also manages the Data Distribution Service (DDS) middleware protocol standard. DDS middleware is specifically designed to handle Industrial Internet applications, and thus plays a key role in the Industrial Internet of Things.

How Can DDS Enable IIoT communication?

Large distributed systems can’t be built without connectivity. Enterprise and human-centric communications are too slow or too sparse to put together large networks of screaming-fast devices. These new types of intelligent machines need a new technology. That technology has to find the right data and then get that data to its intended destination on time. It has to be reliable, flexible, fast, and secure. Perhaps not as obviously, it also must work across many types of industries. Only then can it enable the efficiencies of common machine-based and cloud-based infrastructure for the IIoT.

DDS is not like other middleware; it directly addresses real-time systems. DDS features extensive fine control of real-time, quality-of-service (QoS) parameters, including reliability, bandwidth control, delivery deadlines, liveliness status, resource limits, and (new) security. It explicitly manages the communications “data model,” or types used to communicate between endpoints. Consequently, it’s a “data-centric” technology like a database; DDS understands the contents of the information it manages. DDS is all about the data. In fact, my company (RTI) calls DDS a “DataBus.”

At its core, DDS implements a connectionless data model with the ability to publish and subscribe to data with the desired QoS. Participants are either publishers of data, or subscribers to data.

A DDS-based system has no hard-coded interactions between applications. The DataBus automatically discovers and connects publishing and subscribing applications. Adding a new smart machine to the network doesn’t require any configuration changes. The DataBus matches and enforces QoS.

DDS overcomes problems associated with point-to-point system integration, such as lack of scalability, interoperability, and the ability to evolve the architecture. It enables plug-and-play simplicity, scalability, and exceptionally high performance.

Use Cases

Perhaps the best way to understand DDS is to examine the systems that use it. Applications span the healthcare, energy, defense, transportation, industrial automation, and communications industries.

Energy

Industrial-strength data sharing can improve power generation and distribution, monitor and optimize use, and even power new business models and energy business systems.

Energy systems are key infrastructure. They have many needs, but share key requirements for high reliability, performance, scale, and security. Many are distributed over a wide area, encompassing local- and wide-area networks.

• GC Dam on the Columbia River

The Dam on the Columbia River is the biggest power plant on the continent (Fig.1). Up to 300,000 data values flow through the system. Everything is coordinated by a fully redundant control room. The dam is perhaps the most challenging and mission-critical control system in the power industry.

Its monolithic, hard-to-maintain old system was replaced with a DDS-based control system that’s modern, distributed, secure, and ultra-reliable. The greatest challenges are extreme availability, fault tolerance, performance, security, and wide-area communications.

• Siemens Wind Power

Modern wind turbines have blades that sweep a 120-meter circle, cost more than $1 million, and generate multiple megawatts of power. Each turbine may include up to 1000 sensors and actuators, integrating strain gages, bearing monitors, and power-conditioning technology.

The real challenge, though, is integrating turbines together. A farm may include hundreds of turbines, which requires a truly distributed control system. In a storm, the control system must decide how to take energy out of gusts to generate constant power while managing the loading and potential damage to a half-billion-dollar installed asset.

With DDS, a Siemens Wind Power farm turns into a smart, distributed machine (Fig. 2). It optimizes power. It monitors its own health. It reacts to its environment. It epitomizes the power of the Industrial Internet of Things.

• Microgrids

Dynamic loads and sources like solar panels, local wind generation, and charging electric vehicles change the game for distribution control. The old designs, consisting of central offices balancing power to substations over long, slow lines, simply won’t work. New designs require local, fast control, backed by intelligent generation and distribution architectures.

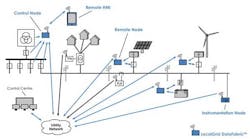

The DDS-based microGrid architecture is being deployed at Canada’s largest utility by RTI’s partner LocalGrid (Fig. 3). It improves grid responsiveness, reduces operational risk, and improves quality of service.

Healthcare

Healthcare is in transition. Advanced device connectivity will change medical practice, lower costs, and improve patient outcomes.

• Connected Medical Devices for Patient Safety

Hospital error is a leading cause of preventable death. Thousands of errors occur in hospitals every day. Many of these errors are caused by false alarms, slow responses, and inaccurate treatment delivery.

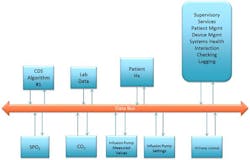

By networking devices, alarms can become smart, only sounding when multiple devices indicate errant physiological parameters (Fig. 4). Smart drug-delivery systems can react to patient conditions much faster and more reliably than busy hospital staff.

• Patient Monitoring

Integrating whole hospitals with thousands of devices presents scalability, performance, and data discovery challenges. To prove the DDS design viable for a large customer, RTI simulated a 1000-bed hospital with over 100,000 devices (Fig. 5). DDS handled realistic scale, performance, and discovery. Since it’s important to communicate real-time waveforms and video, the potential network-wide dataflow is large. DDS filtering, and the ability to propagate those filters to the sender, eliminates wasted bandwidth.

• Computed Tomography (CT)

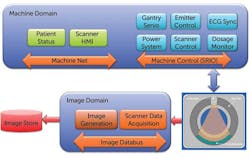

A modern CT imager is a marvel (Fig. 6). It generates X-rays by firing high-energy electrons at a spinning tungsten disk. Beam formers direct the X-rays through the patient to collimating receivers. The entire system spins on a gantry 360 degrees around the patient fast enough to freeze motion. The controller must get all the parts ready and fire them at the right time to coordinate with the patient’s heartbeat. Then, it sends the megabytes of raw data to a processor to back-project a 3D image.

RTI Connext DDS integrates all of these pieces in real time (Fig. 7). With precise QoS control, feedback and event signals are delivered fast enough to ensure a quality image.

• Mevion Proton Beam Radiation Therapy (PBRT)

High-energy proton beams have little interaction with tissue until they reach a critical speed. Then, they deposit nearly all of their energy in a very short distance. Thus, proton therapy lets physicians tailor radiation doses to attack tumors while minimizing radiation damage.

This requires a particle accelerator, a superconducting synchro-cyclotron, scaled down to fit in a large room. The cyclotron controls extremely rapidly-changing magnetic fields to accelerate and contain speeding protons. The control system handles patient positioning, treatment planning, motion control, beam scattering, field shaping, magnetic control, ion sourcing, and dosimetry. It’s an intelligent machine that’s accurate enough to zap a retinal cancer without damaging vision (Fig. 8). The first system became operational in late 2013.

Transportation

Real-time distributed connectivity will forever change transportation. From smart cars to intelligent tracking systems, things that move are fast moving into the Internet of Things.

• NAV Canada Air-Traffic Control

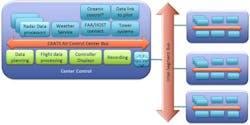

NAV Canada, the air-traffic control authority for Canada, is implementing continent-wide air-traffic control with RTI Connext DDS. The Canadian Automated Air Traffic System (CAATS) spans seven major centers and will connect to hundreds of airport towers. It controls from coast to coast, from the US border to the North Pole, and to oceanic travel in the North Atlantic and Pacific. Performance, scalability, and 24/7 reliability across these large geographical regions are key (Fig. 9).

CAATS uses the DDS filtering QoS to manage data flow (Fig. 10). For instance, an operator display can request only aircraft tracks within five miles, below 5000 feet, descending, and approaching. Connext DDS sends that specification to the publisher, and filters it on the writer. This is only possible because DDS is data-centric, so it can understand the contents of the information it conveys. Writer-side filtering prevents sending most of the data required by “message-centric” middleware. This saves bandwidth and enables scalability.

• Volkswagen Smart Cars

VW is implementing Driver Assistance and Integrated Safety with DDS. The system helps avoid obstacles, detect lane departures, track eye activity, and safely negotiate bends. DDS connects all components into a single intelligent machine (Fig. 11).

In 2013, VW demonstrated a version of this software running on an electric vehicle. It was able to drop off its passengers, drive autonomously down the block to a recharging station, and then return fully charged. Seemingly, driverless car technology is rapidly becoming reality.

Lessons Learned from DDS Applications

The above examples are only a few of the hundreds and hundreds of DDS applications. Others include distributed vehicle testing at Audi; control of advanced mining machinery at Joy Mining; huge SCADA systems with 300k points at NASA KSC; real-time voice and video communications at Excelis; PLC communications at Schneider; and more. DDS has application proof points in dozens of industries across the IIoT landscape.

Most DDS applications are distributed systems with at least two of these three fundamental characteristics:

• Reliability: Five minutes (or less) of downtime is considered failure, or even disaster.

• Performance or scale: The system expresses timing needs in milliseconds or microseconds, or connects hundreds of applications, or deals with tens of thousands of data values.

• Longevity: The code lifecycle is at least three years, requiring coordinated development and application evolution.

Any application that checks all three boxes can really leverage DDS. No other technology comes close. Even the metrics used by other technologies fall short. For instance, enterprise systems talk about “five 9s” of reliability, which translates to about five minutes of downtime a year. This may suffice for a website or business system. But would you fly in an airspace that drops air-traffic control “only” once a year? Would the economy succeed with a power grid that “only” fails every few months? The IIoT must meet very different expectations.

Future End-to-End Integration

Tomorrow’s IIoT systems won’t just connect the real-time “operational” systems. Future systems must optimize performance, predict maintenance issues, and provide system-wide intelligence to business systems. These operations require deep integration between real-time control and cloud-based “big data” analytics. To support these integrations, infrastructure services will be needed to build larger systems.

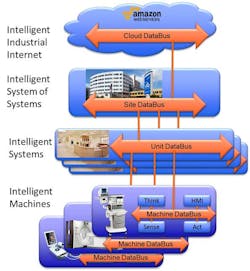

For instance, a “Routing Service” (RS) can bridge subsystems. Routing is the process of assembling a hierarchy of local intelligent machines into connected units, sites, and larger cloud-based system infrastructures. RS works by connecting data models, allowing systems to translate and export the right data. It thus enables systems-of-systems integration.

This is critical, because large systems must develop independently. Developers of a hospital CT imager, for instance, can create the data model needed to control the system. Other hospital systems, such as ventilators, ECG monitors, and drug delivery systems, will obviously need very different machine data flows. Consequently, each will have very different data models, implementation timing, and upgrade paths. By controlling data export, RS buffers between systems.

Of course, RS must also combine systems. The next level up, for instance, needs common data, such as use statistics, location information, and patient health records. With RS, the implementer of a common framework can convert the correct data from the lower-level system into the data model of the encompassing unit.

RS chooses the correct information from each lower-level system and translates it into the “language” (data model) needed higher in the hierarchy. By also passing along QoS parameters, the entire system will look, at any one level, like a single logical data space. For a large system, that data space may hide a very complex actual topology. This abstraction enables large, integrated systems.

Other infrastructure services offer interfaces to databases, web services, Enterprise Service Buses like CAMEL, and even queuing. With these services, a data-centric design can integrate high-performance machine systems all the way up to full cloud-based enterprise technology (Fig. 12).

Conclusion

The really exciting potential of the IIoT is to create bold new intelligent machines and vast distributed systems, ultimately changing the world across many industries. Its applications define the future: renewable energy, cars that drive themselves, planes that fly themselves, smart medical devices, and smart hospitals.

DDS is a unique communications technology designed to handle data at physics speeds. It offers controlled access to exactly the right data, as well as the extreme reliability, security, and scalability needed for real-world infrastructure.

This file type includes high resolution graphics and schematics when applicable.

Critically, this isn’t just speculation. DDS is proven on real systems representing the breadth of the IIoT. From day one, DDS evolved on challenging real-world industrial systems across dozens of industries. It’s the only common platform in such widespread actual use.

The future of the IIoT must integrate these proven applications into larger systems-of-systems that bring the power of cloud analytics and business intelligence to industrial systems. This is the core vision of the Industrial Internet. DDS is the right standard protocol to fulfill that vision, because it provides both the extreme capabilities required by intelligent machines and the needed integration to extend to cloud-based analytics and optimization.

Stan Schneider, CEO of embedded-middleware specialist Real-Time Innovations (RTI), is an original author of software ranging from performance and monitoring tools to robotics control systems. He completed his PhD in electrical engineering and computer science at Stanford University, and holds a BS and MS from the University of Michigan. He’s also a graduate of Stanford's Advanced Management College.

About the Author

Stan Schneider

CEO, Real-Time Innovations

Dr. Stan Schneider is CEO of Real-Time Innovations (RTI), the Industrial Internet of Things connectivity company. Stan serves as Vice Chair of the Industrial Internet Consortium (IIC) Steering Committee. He also serves on the advisory board for IoT Solutions World Congress, and chairs OpenFog's Fog World keynote committee. He was named Embedded Computing Design’s Top Embedded Innovator Award 2015 & IoTOne’s top-10 most influential in the IIoT 2017.He holds a PhD in EE/CS from Stanford.