The prospect of delivering healthcare that’s more responsive, more cost-effective, and able to improve quality of life for patients keeps pushing the demand for cutting-edge medical electronics. Axis Research Mind recently predicted the market would grow to $372.4 billion by 2018 in its December 2013 report “Medical Electronics—Global Trends, Estimates and Forecasts, 2011-2018."

The report suggests multiple sectors of the healthcare industry are clamoring for the latest and greatest. These include imaging systems like X-ray, magnetic-resonance-imaging (MRI) and ultrasound systems, and other hospital/clinical-center equipment such as monitoring and surgical systems.

This file type includes high resolution graphics and schematics when applicable.

In addition, personal medical-monitoring devices promise tremendous benefits for healthcare professionals and patients by helping to manage a wide variety of conditions such as diabetes, heart disease, or arrhythmia. With these personal monitors, professionals are able to improve standards of care, even with increasing numbers of patients. Patients, for their part, can enjoy more functional lives at home without having to make regular visits to a consultant.

Monitors and imaging systems often depend on precision analog signal-processing circuitry at the front end of the signal chain to condition signals such as the output of an MRI sensor, ultrasound sensor array, or the photodetector in a pulse oximeter. Other types of medical monitors, such as implantable pacemakers and cardioverter defibrillators, are life-critical and require consistently accurate performance as well as extreme reliability from all electronic components in the circuit. These include capacitors, which often have a vital role in signal conditioning, filtering, and power supply stabilization.

Medical Equipment Needs

Demands from medical equipment designers typically go well beyond those experienced in general-purpose commercial applications. Designers often need high-capacitance values in small case sizes, particularly for implantable devices. In addition, the capacitors must display very high reliability with failure rates in the low parts per million or better—over lifetimes of ten years or more. In some applications, such as implantables, the operating temperature can be assumed to be reasonably constant.

Still, the capacitance change with voltage must be minimized to maintain consistent signal-handling accuracy. On top of that, long battery life is often vital, particularly for implantables. Capacitor technologies that reduce leakage current allow applications to run longer on tiny batteries.

Delivering devices that offer the required performance and reliability means incorporating a combination of new materials and construction technologies, as well as enhanced testing and screening procedures dedicated to the needs of the medical electronics industry.

The Drive for Miniaturization

General industry-wide demand for smaller printed-circuit-board (PCB) sizes, as well as reduced cost, has pushed ceramic capacitors toward base-metal electrode (BME) technology in recent years. Typically, these use nickel in the electrode system. A nickel-based BME ensures higher voltage-stress capability compared to earlier precious-metal electrode (PME) systems, such as palladium-silver alloy.

Thanks to the higher voltage-stress capability, multi-layer ceramic capacitors (MLCCs) can be designed with thinner dielectric layers, thus increasing volumetric efficiency (capacitance per volume, or CV). Improved coating and handling processes enable manufacturers to achieve tight control when producing dielectric layers at thicknesses of than 1 µm, and today’s BME system can support hundreds of layers in the same device.

Several technologies have been developed to further enhance capacitor efficacy, such as KEMET’s F-Tech flawless technology, which minimizes impurities in the anode and dielectric of tantalum capacitors. It removes latent defects that can induce capacitor failure, and reduces leakage current to enable battery-powered applications to run longer. F-Tech also eliminates the degradation of leakage current, which can deteriorate by 1.5 orders of magnitude in standard tantalum capacitors.

Most recently, new C0G and X7R dielectrics have arrived that can support increased capacitance, leading to unprecedented CV with guaranteed stability. The EIA specification for X7R dielectrics, for example, requires that the capacitance variation from the room temperature value (ΔC/C) should be within ±15% over the temperature range of –55 to 125°C.

To satisfy this specification while enabling higher capacitance, the new X7R dielectrics are based on barium titanate (BaTiO3). Barium titanate has high purity, crystallinity, and a well-controlled microstructure, which provide the foundation for a high-capacitance device. Dopants and additives ensure high reliability under bias and temperature conditions.

The EIA specification for C0G dielectric, on the other hand, requires ΔC/C within 0±30 ppm/°C over the temperature range –55 to 125°C. KEMET developed a unique C0G dielectric chemistry for BME ceramic capacitors that’s based on calcium zirconate (CaZrO3). This offers benefits such as high insulation resistance, high reliability, and high Q factor at reduced dielectric thickness. Today’s coating processes enable significantly increased volumetric efficiency among BME C0G MLCCs, making capacitance values of 1μF possible in the 2824 case size, or 0.68μF in a 2220.

Voltage Effect on Time to Failure

Highly accelerated life testing (HALT) performed on the latest C0G and X7R capacitors has shown that voltage impacts time to failure more than temperature. For an implantable application, the temperature will usually be close to 37°C.

Under the known application conditions for implantables, and when operated at 50% of rated voltage, HALT tests projected a median time to failure of significantly more than 100,000 years. Projected failure rates are practically zero ppb (parts per billion) for C0G devices in service for up to 50 years. Similarly, projected failure rates for an X7R dielectric system have been shown to be less than 1 ppm up to 10 years and less than 3.5 ppm up to 50 years.

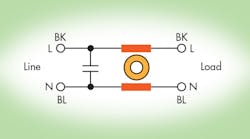

Non-implantable applications like imaging equipment or medical lasers also often require high capacitance within a small PCB area. To satisfy these types of demands, innovative packaging technologies, such as vertical stacking of ceramic capacitors in standard EIA case sizes (e.g., 1210), give designers flexibility to boost capacitance without increasing footprint (Fig. 1). Stacked tantalum MnO2 capacitors are also available in array sizes from 2x1 to 3x2.

Eliminating Distortion and Interference

In imaging equipment such as MRI scanners, any magnetic signature of devices in the system’s electronic circuitry can distort the sensed signal. To prevent this, special non-magnetic capacitors can be used. For instance, KEMET’s tantalum capacitors, such as the T493/494/495 MnO2 series or T520/521 polymer-electrode series with pure tin terminations, target applications requiring non-magnetic properties.

This file type includes high resolution graphics and schematics when applicable.

When installing equipment such as X-ray or MRI instruments in shielded rooms, signal and power feed-through capacitors that can attenuate interference signals at up to gigahertz frequency levels offer a cost-effective alternative to dedicated filter units. Cost savings can be particularly extensive when multiple signal or power lines need protection.

Small-signal filtering applications, for example, can be served by film capacitors that offer high pulse-current capability, self-healing properties, and stability over a –55 to 125°C temperature range. On that front, KEMET developed its AF series capacitors targeting signal feed-through applications. Available in a wide range of capacitance values, the devices come in sealed metal containers with wire, tag, or fast-on termination options. Power feed-through capacitors, such as the KEMET F.LL.DH and F.LL.DU series (from the 16A DH.016A.025.I0 to the DU.300A.945.I0 with rated current of 300 A), feature robust metal cases featuring lock-nut or flange-mount options and threaded terminations.

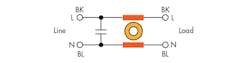

Applications requiring electromagnetic filtering in which no, or limited, leakage current to protected earth is accepted could opt for a dedicated filter without a Y capacitor. The absence of the Y capacitor prevents such leakage. A family of these devices developed by KEMET, targeted at 250-V ac applications, are designed to operate with low insertion losses while attenuating frequencies up to 100 MHz. The FLH7A01568DK, for instance, has a rated current of 7.0 A (Fig. 2).

Closing the Loop on Medical Device Quality

In addition to technical development aimed at improving performance and reliability, the demands of the medical sector typically require more careful screening and handling. Taking these lengths helps ensure that only devices known to meet minimum specifications are released.

KEMET, for example, separated the end-of-line procedures for its medical ceramic capacitors from those of standard commercial parts. It also set up a dedicated end-of-line medical test center, in addition to assigning quality, production, process engineering, production control, and product-management specialists specifically to manage its medical MLCC lines.

Axel Schmidt is a senior field applications engineer at the KEMET Corporation.