This file type includes high resolution graphics and schematics.

LEDs are the most efficient way to turn an electric current into illumination. When a current flows through a diode in the forward direction, it consists of surplus electrons moving in one direction in the lattice and “holes” (voids in the lattice) moving in the other. Occasionally, electrons can recombine with holes. When they do, the process releases energy in the form of photons.

This is true of all semiconductor junctions, but LEDs use materials that maximize the effect. The color of the light emitted (corresponding to the energy of the photon) is determined by the semiconductor materials that form the diode junction.

The latest high-brightness (HB) white LEDs are made possible by the discovery of semiconductor materials that produce blue or ultraviolet photons. In addition to the diode, an HB package contains “yellow” phosphors on the inside of its lens. Some “blue” photons escape, but others excite the phosphors, which then give off “yellow” photons. The result can be tuned in manufacturing to produce “white” light.

A great deal of LED engineering relates to controlling the quality of this light. From a circuit standpoint, there are a number of ways to interconnect multiple LEDs to increase and manage light output. The general approach is to drive series strings with a constant current, but there are subtleties to interfacing the drivers with ac supplies and control schemes.

Table Of Contents

• Electroluminescence At Semiconductor Junctions

• Driving-Circuit Design Example

• Special Considerations: Power Factor

• Controlling LEDs In Buildings And Street Lighting

Electroluminescence At Semiconductor Junctions

When current is flowing in the forward direction through a semiconductor junction diode, each time an electron and a hole recombine, energy is released as a photon. The color of the light (the energy of the photon) is determined by the energy band gap of the semiconductor material. For example, aluminum gallium arsenide (AlGaAs) yields red, indium gallium nitride (InGaN) yields green, and zinc selenide (ZnSe) yields blue.

The light from red, green, and blue LED diodes can be combined to produce white light, but with limited brightness. More commonly these days, HB white diodes combine a blue InGaN diode with a yellow phosphor, usually cerium-doped yttrium aluminum garnet (Ce3+:YAG) on the inside of the device package. Photons from the phosphor are perceived along with photons from the diode junction.

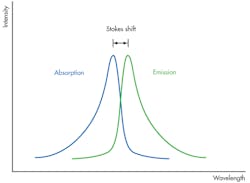

Broadly speaking, the eye perceives the result as white. More narrowly, it’s a bit more complicated. There is a quantum effect called Stoke’s Shift in which a photon emitted by the phosphor photon has less energy than the photon it absorbed from the blue LED (Fig. 1). In an HB white LED, a fraction of the blue light is Stokes-shifted. LED makers take advantage of this phenomenon by using multiple phosphor layers with different photon energies to spread the emitted spectrum, which results in a more natural lighting effect.

LEDs for lighting are rated in terms of luminous efficacy: the ratio of luminous flux to electrical input power. It is expressed in lumens/watt. Lumens are defined in terms of the light from a source that emits a standardized level (one candela) of luminous intensity (which most people would call brightness) of over a solid angle of one steradian. Those units account for the sensitivity of a human eye by accounting for something called the luminosity function, which standards bodies have agreed represents the eye’s response to different wavelengths.

In other words, the lumen part is calibrated to what has been decided is an average human’s visual system. For a rough comparison, the sun has a luminous efficacy of 93, and an ordinary tungsten light bulb has a luminous efficacy of 15. The best HB LEDs today hit between 130 and 150, and the rate of improvement doesn’t seem to be flattening out. That doesn’t mean they’re brighter than the sun, though. They’re just more efficient than the sun’s thermonuclear reaction at putting out photons at the wavelengths we can see. In fact, they’re 10 times more efficient at it than old-fashioned light bulbs.

Color Rendering Index

Using multiple “yellow” phosphors with a blue or ultraviolet LED improves the color-rendering index (CRI) of the device. CRI is a measure of how closely the colors of an object being illuminated artificially resemble those colors when they are viewed under actual sunlight. For the LED maker, a high CRI implies lower luminous efficacy than single-color LEDs. But for natural-looking colors, good CRI is essential, so it presents an engineering tradeoff with luminous efficacy.

Color Binning

For individual white LEDs, “whiteness” varies from unit to unit, so LED makers sort and bin them to enable lighting designers to mix and match bins to achieve the precise flavor of white they want. This binning follows a model developed in the 1950s for then-new fluorescents. But month by month, the bins are getting tighter, making it easier to achieve a specified color with fewer LEDs. That’s a good thing, because those steady improvements in luminous efficacy mean that it takes fewer and fewer LEDs to achieve a specified intensity of light output.

HB white LEDs work by combining blue-emitting LED diodes with phosphors that emit photons for different colors that when mixed add up to white light. According to Cree, most of the recent advances in HB white LED manufacturing arise from the techniques employed for depositing the phosphor so it will be struck by the maximum number of primary photons and will, in turn, radiate the maximum number of secondary photons in an optimum pattern. In other words, just laying down a “glob” of phosphor on top of the diode junction isn’t a very good approach. (An “optimum pattern” facilitates the use of lenses and reflectors in shaping the light from all the LEDs in the fixture.)

This file type includes high resolution graphics and schematics.

LED Packaging

Basic optical principles create a bit of difficulty in getting photons out of the diode semiconductor material, which tend to have high refractive indices. If a photon cannot cross the interface between the semiconductor material and the air (or vacuum) surrounding it, it’s reflected back into the material and absorbed. If the semiconductor material were cubic in shape, it would only emit light more or less perpendicular to one face or another of the cube. (Think back to Physics 102 and the part of the chapter on optics that dealt with “critical angle.”) So, simply dicing a wafer of LEDs and treating them as if they were just another semiconductor chip would be unsatisfactory.

If one weren’t dealing with epitaxial diode materials deposited on a flat substrate, one might think of emulating a diamond cutter and faceting the material. But the more practical approach is to pot the LED in a transparent plastic material with a refractive index between the indices of the semi material and air while shaping the glob of plastic into something more spherical, or hemispherical, that increases the critical angle at both interfaces.

LED Pricing Trends

Logic devices have Moore’s law, which has little validation except history. LEDs have Haitz’ law, named after Roland Haitz, which says that commercial LED maximum light output doubles approximately every 36 months. Haitz’ law leads to implications for designers of LED-based products: whatever the rated light output of the most expensive LED is today, it will be available at baseline prices a year and a half from now. Future products with the same light output will require fewer and fewer LEDs.

Driving Single LEDs

It seems as if driving LEDs ought to be simple. They’re diodes, they have a certain forward voltage drop, and their light output depends on current, for which there is a do-not-exceed value for any given diode. That seems like a manageable set of parameters, doesn’t it? But then it starts getting complicated. As with conventional diodes, LED current varies exponentially with the voltage, i.e., a small change in voltage can cause a large change in current. That’s why, in most cases, LEDs are driven with constant-current sources.

Driving LED Arrays

Few applications use only a single LED. Whether it’s for a screen-backlighting array or for LEDs in a streetlight or a replacement for an incandescent or fluorescent lamp, most designs need more than one LED. Therefore, one of the first decisions a designer must make is whether to drive the LEDs in series, in parallel, or as a parallel array of strings. Generally, it isn’t a good idea to drive a number of single LEDs in parallel because that can lead to non-uniform current sharing, even when the LEDs are all rated for the same forward-voltage drop.

Driving LEDs in series introduces the question of what happens when a single LED fails as an open circuit. That can be dealt with somewhat expensively by providing parallel Zener diodes or silicon-controlled rectifiers (SCRs) across each LED. SCRs are the more attractive choice because they dissipate less power if they have to conduct around the failed LED.

In a design using multiple parallel strings, including a separate driver for each string is obviously more expensive than using fewer drivers (ideally one) with sufficient output capacity. Even though an approach using parallel strings also tends to even out the current-sharing problem, it is still necessary to use a ballast resistor for each string to accommodate variations in forward voltage drop (Vf) across the diodes.

To calculate a resistor value, assuming a ±10% variation in forward voltage drop across the string and a need to match the currents in each parallel string to within ±20%, start by assuming that for each string the sum of the LED forward drops, plus the voltage across the ballast resistor, should equal 80% of the nominal output voltage of the driver. From that, it’s possible to calculate both the necessary ballast resistance and the maximum current capacity of the driver. An easier alternative is to buy the series/parallel string arrays matched and cross-connected, as in Philips’ Luxeon Flood products.

Driving-Circuit Design Example

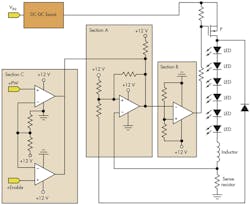

To illustrate a common design approach in a backlighting application, consider this design from Endicott Research Group, where a constant current-chopper driver provides a dc current with low ripple to an LED string used to edge-light a graphic display (Fig. 2).

This file type includes high resolution graphics and schematics.

The pass switching device (P at the top of the LED string) is a P-channel FET that provides the current to the string and, in conjunction with the inductor, sense resistor, and boost voltage, establishes the chopping current and frequency. The dc-dc boost stage is a closed-loop boost supply that provides sufficient voltage to drive current to the LED string with at least 2 V of headroom.

The part of the diagram designated Section A shows a comparator and associated resistors that form a positive hysteresis circuit. It compares the voltage across the sense resistor to a known reference. Section B shows another comparator and associated resistors that buffer the Section A output to ensure proper hysteresis and provide drive to the pass device. Section C supplies LED on/off and dimming control. The +ENABLE input turns the backlight on or off, and +PW pulse-width modulates the chopper driver on and off for dimming.

Special Considerations: Power Factor

When a general lighting system requires a lot of power, then the first power-conversion stage, the ac-dc stage, gets interesting. That’s because while it’s a long way from the LEDs, the U.S. Department of Energy (DoE) and the European Union have made it clear that they want it to exhibit a very clean power factor, which is difficult because of that darned capacitance on the output of the rectifier bridge.

This is approached in different ways. The EU’s IEC61000-3-2 specifies acceptable levels for the first 32 harmonics of the ac line frequency, while the DoE’s Energy Star program (which is voluntary but enforced by the buying power of the U.S. government) specifies a power factor of at least 0.7. On top of that, real customers for general lighting applications demand a minimum power factor of 0.9, so that’s what designers aim for.

That in turn requires a somewhat sophisticated flyback topology for the first stage, with operation in critical conduction mode. Subsequent stages of switching regulation, buck, boost, or buck/boost support a final stage that provides the drive to the string or parallel strings of LEDs. This is generally a switcher also.

Alternatively, it is possible to use linear regulators, which makes it less expensive to achieve the required overall efficiency. The output stage, in that case, could be designed to supply the full voltage needed by the sum of the string’s forward voltage drops while dissipating less than a volt in its own pass transistors.

Controlling LEDs In Buildings And Street Lighting

Some LED-replacement-bulb dimming ICs are compatible with legacy triac controls intended for incandescent bulbs (see “LEDs Gain Ground On Their Illumination Rivals,” p. xx). The fundamental challenge in that environment is to present a load that looks like the resistive impedance of a tungsten filament and to convert the triac’s time-chopped line-voltage ac waveform, which is based on the position of the dimmer’s control knob into a series of duty-cycle controlled, constant-current dc pulses at a low voltage suitable for the screw-in LED replacement bulb or fluorescent tube. A further challenge is to achieve a power factor close to unity on the ac line.

Generally, all this is accomplished with a critical-conduction mode flyback ac-dc stage and a dc-dc back end, although some IC manufacturers manage to do it in one stage. Another differentiator between manufacturers is how the feedback is accomplished. Some IC makers have ways of getting around the need for optical isolation. The more interesting differentiators include designing ICs versatile enough to be used in all the different variations in other manufacturers’ triac dimmers and reducing the number of external components so that unit cost is low and the entire circuit can fit into the base of the replacement bulb, even if the base of the bulb is much smaller than a conventional bulb base (Fig. 3).

All of this is only relevant if a circuit designer works for a company that makes replacement bulbs. A newer challenge relates to LEDs that are used for street lighting, parking garages, warehouses, and general outdoor lighting. There, the dimming requires a different approach, because it is being applied in new construction or large retrofit jobs to external LED fixtures that have been driven by external ballast circuits.

Traditionally, an analog interface called 1-10V has been used. It uses a simple 0- to 10-V dc control level to set brightness. But in these applications and in smart buildings, the Digital Addressable Lighting Interface (DALI) is replacing 1-10V. It is described in the fluorescent lamp ballast standard IEC 60929 under Annex E. The ZVEI committee of the German Central Association of the Industry controls the standard for electric and electronic Products within the Activity Group “DALI.”1 Of course, a hard-wired DALI is connection is only the beginning. LED lighting in modern smart buildings is just as likely to be controlled by the ubiquitous ZigBee interface (Fig. 4).

Reference

1. For a detailed explanation of DALI, go to http://www.dali-ag.org/c/manual_gb.pdf.

This file type includes high resolution graphics and schematics.

About the Author

Don Tuite

Don Tuite (retired) writes about Analog and Power issues for Electronic Design’s magazine and website. He has a BSEE and an M.S in Technical Communication, and has worked for companies in aerospace, broadcasting, test equipment, semiconductors, publishing, and media relations, focusing on developing insights that link technology, business, and communications. Don is also a ham radio operator (NR7X), private pilot, and motorcycle rider, and he’s not half bad on the 5-string banjo.