This file type includes high-resolution graphics and schematics when applicable.

With current market dynamics constantly driving toward shorter design cycles, enhanced system functionality, and more portable end systems, the need for a new methodology to simplify these challenges without adding design complexity is a must. This article will address some key system challenges for control and measurement that are topical across many applications, including data-acquisition systems, industrial automation, programmable-logic controllers, and motor control.

The article will also explore the latest advances in bipolar digital-to-analog converter (DAC) architectures and how these topologies can address end-system challenges, which include adding even more functionality and intelligence within the same or reduced space. On top of that, it will discuss discrete and more functionally complete solutions, as well as outline a number of alternatives to traditional design topology that support higher flexibility in design reuse and system modularity.

It should be noted that the figures provided below are not the actual schematics, but illustrations on how applications could be achieved with multifunctional DACs and other components. While it doesn’t include aspects such as circuits for power supplies, bypassing, and other passive components, these diagrams illustrate how applications can be implemented in general.

Data-Acquisition Systems

Data-acquisition systems (DAQs) are used to measure an electrical or physical singularity, such as voltage, current, or pressure, with a microcontroller or microprocessor for data-processing capability. DAQs consist of sensors, amplifiers, data converters, and a controller with embedded software that controls the acquisition process.

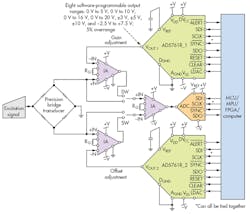

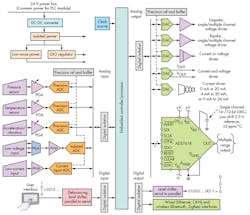

In a process-control application, it’s critical that the sensor is sensitive enough to preserve the quality of the signal to be measured. But even if the sensor is sensitive enough, the signal-chain errors such as gain and offset could still interfere with the signal quality. High-performance applications employ DACs in automatic calibration of the conditioning circuits in data-acquisition systems. Figure 1 shows the block diagram of a pressure-sensing system. It illustrates how bipolar DACs can be used in an automated gain and offset calibration scheme.

The precision bridge transducer receives an excitation signal from a pressure sensor and produces an output voltage. Due to the low amplitude of the transducer’s signal, an instrumentation amplifier is typically used as a signal multiplier. This low-amplitude signal is susceptible to errors. Such errors are usually caused by drift due to changes in temperature, parasitic errors across circuit boards, and tolerances of passive components.

With the use of a bipolar DAC, gain and offset calibrations can be implemented into the system to dynamically correct the errors as the system operates over time. Depending on the level of adjustment and the polarity required, a complete, high-resolution and multifunctional bipolar DAC can greatly simplify the calibration process. The DAC can be programmed through a high-speed, 4-wire SPI interface with a serial data output (SDO) line available to facilitate daisy-chain and read-back operation.

Industrial Automation

There’s a broad array of applications within the industrial-automation space. Regardless the application though, the functionality and performance of such automated systems lies in their signal acquisition and control units. On the acquisition side, the sensitivity of the sensors, adaptability of the conditioning circuits, and the speed of acquiring correct information from low-level signals is very important. On the control side, the flexibility to adapt to the requirement of various actuators and drivers is vital.

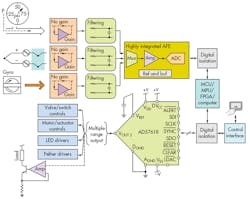

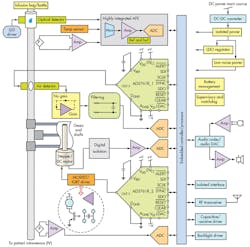

Figure 2 shows an example of an industrial automated system. A thermocouple with cold-junction compensation is used to measure the temperature of industrial equipment, such as a laser machine or heavy duty motor. The voltage is gained up, filtered, and sent to an integrated analog-front-end (AFE) IC for conversion and the digital data is passed into the processor for analysis.

Based on the processed data, the processor sends signal to a control DAC, which is also fully isolated, to drive an industrial fan, activate cooling apparatus such as a Peltier, or open the valve of a water-cooling system. In addition, the user can input an override command via a control-interface device.

The same system can be adopted for pressure and vibration measurement and control. A pressure sensor system can typically be used for oil and chemical tank monitoring; while a gyroscope system could be used for vibration monitoring of fast-moving machine heads. These applications share the same AFE, which is fully isolated from the external environment.

A high-voltage, high-resolution, bipolar DAC with low-drift internal reference and software-selectable output range is a practical replacement for multiple DACs or a single-multiplexed DAC. It provides unipolar and bipolar voltages while maintaining the same accuracy with an option of over-range output. The bipolar DAC supports the actuator’s different needs, including the adjustment of the control unit through software, thus avoiding hardware modifications. This new industrial control approach also helps to minimize board space and reduce cost.

Programmable-Logic Controllers

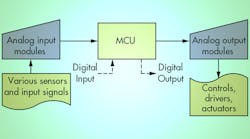

Programmable-logic controllers (PLCs) incorporate power supplies, central processing units, and several analog and digital I/O modules to control, actuate, and monitor complex machine variables. PLCs are widely used across industries, offering extended temperature ranges, immunity to electrical noise, and resistance to vibration and impact. In a fundamental process-control system building block (Fig. 3), an input signal reporting on the status of a process variable is monitored via the input module and transferred to the MCU to be analyzed. Based on the results of this analysis, a response containing the necessary arrangements is managed by the output module to control the devices in the system.

Figure 4 shows a more complete industrial PLC system, including an embedded controller/processor as the main system controller interfacing to the fully isolated input and output modules. Excluding the power-supply module, the system is divided into four subsystems that differentiate the analog input, analog output, digital input, and analog output modules.

Several types of sensors are deployed to acquire analog signals of different amplitudes and frequencies. These signals need to be pre-processed and converted into digital form for further analyses. Programmable gain amplifiers condition the small input signals so that they can be accurately measured and converted into their digital representation by analog-to-digital converters (ADCs). Isolation is required to protect the controller or processor from possible unexpected overvoltage coming from the field, for which optical or integrated isolators are placed among the processor and the input and output modules.

The accuracy and resolution requirements for the input and output modules are considerably distinct. While the input modules monitor highly precise and accurate data acquisitions from the process, the output modules essentially adjust the output with a 16-bit resolution and accuracy in high-end applications. As a result of these conditions, sigma-delta ADCs are commonly used for input modules in PLC systems from which a wide range of isolated, single- and multichannel and simultaneous sampling ADCs are available in the market.

Output modules may offer precision voltage DACs, precision current DACs, or a combination of both. Several methods allow current and voltage levels to be generated for the PLC’s analog output. The evolution of precision bipolar DACs, providing extra functionality and a high level of integration, significantly benefit PLC systems from reduction of system complexity, board size, and cost.

Motor Controls

DACs perform an integral function in motor-control loops, for example, in infusion pump systems (Fig. 5). Infusion pumps are widely used in human healthcare to provide medical treatment to patients of all ages. The role of an infusion pump is to deliver fluids, medication, or supplements to the patients’ cardiovascular system in an intermittent or continuous procedure.

Although infusion pumps require a qualified user to program the specific parameters for the treatment, the implicated advantages over manual administration influence greater user confidence. The ability of these instruments to accurately deliver tiny dosages at scheduled intervals in a self-operated mode negates the need for a nurse or doctor to manually control the flow of fluid to the patient.

Doctors and medical administrators can depend on the safety of infusion pump systems to display real-time system information on dosage limitations for titration safety, or to prevent overdose. It also creates more confidence that the physical delivery mechanism itself will be reliable and accurate.

During operation, the microcontroller receives the monitored speed and direction signals from the dc motor, which are analyzed and adjusted (if required) to meet the set-point. The DAC in the feed-forward path makes system adjustments while the ADC in the feedback path monitors the effect of each adjustment. The desired set-point voltage set by the DAC is amplified through the driver network to provide the required drive current to the dc motor.

Analog Devices (ADI) offers high-performance analog and mixed-signal processing solutions for detecting, measuring, and controlling sensors and actuators used in chemistry analyzers, flow cytometers, infusion pumps, dialysis equipment, ventilators, catheters, and many more medical instruments. In particular, ADI’s AD5761R, a high-resolution, bipolar DAC with eight available software-selectable output ranges that maintains a common accuracy, is designed for motor-control applications, supporting the different voltage swings needed by motors.

Conclusion

DACs play a key role in determining the performance and accuracy of many control systems and simple conversion circuits, as well as other complex applications. The AD5761R family, which is a complete 16-bit resolution precision bipolar DAC with multiple programmable output ranges, will find homes in a number of the aforementioned applications. It offers highly configurable ranges (0 V to 5 V, 0 V to 10 V, 0 V to 16 V, 0 V to 20 V, ±3 V, ±5 V, ±10 V, and −2.5 V to +7.5 V; 5% over-range) to suit DAQ systems, industrial automation, programmable logic controllers, and motor controllers. Integration within the family, including an output buffer and a buffered 2-ppm/°C internal reference, helps simplify board design, reduce board size, and minimize power consumption and cost.

Estibaliz Sanz Obaldia received her bachelor’s degree in electronic engineering and automation from University of Deusto. Estibaliz joined ADI in 2010 and works as an applications engineer in the Precision Converter Group in Limerick, Ireland. She can be reached at [email protected]

Junifer Frenila received his bachelor’s degree in electronics and communications engineering from WVCST in 2005. He joined ADI in 2006 and works as a design evaluation engineer in the Precision Converter Group in ADI Philippines. Junifer is currently working on his doctoral degree in electronics engineering at Mapúa Institute of Technology. He can be reached at [email protected]