Q&A: Cadmium-Free Quantum Dots Offer Low-Risk Benefits of True Color

Quantum-dot display is a neat technology. For instance, it helps provide a whiter light source from LEDs used to backlight LCD displays. A light with a wider spectrum delivers better color than using LEDs alone. The original quantum-dot implementations incorporated cadmium, which is a very undesirable pollutant. Thus, Nanoco went about creating a cadmium-free quantum-dot technology. I talked with Dr. Michael Edelman, CEO of Nanoco, about the company’s approach and why he feels its technology is superior to competing quantum-dot solutions.

Wong: Tell us a little bit about Nanoco.

Edelman: Nanoco was founded in 2001 by a team of scientists who figured out how to harness the power of tiny semiconductors called quantum dots. The technology was brought out of research labs at the University of Manchester and to the manufacturing floor where it could be produced at scale. Nanoco is the world’s only manufacturer of cadmium-free quantum dots—since the world has become more familiar with the power of the technology, the cadmium-free distinction is an important one. I’ll elaborate more on that later. Quantum dots have the potential to change a number of industries—solar, lighting, bio-imaging—but we’re really enthusiastic about their role in display. This is a particularly exciting time for our company because we’re in numerous customer trials with the aim to bring quantum-dot displays to store shelves, something we should be able to make happen in short order given our exclusive licensing agreement with the Dow Chemical Company.

Wong: Can you talk about the visual quality of a quantum-dot display, and what makes it superior to its predecessors?

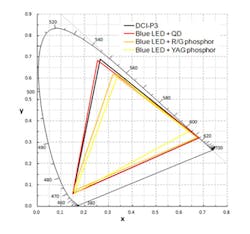

Edelman: It’s all about the color – beautiful, vivid color that goes well beyond what’s currently available. We believe the next great achievement in display will ensure what the viewer sees on screen looks true to life. That’s as much to do with color as it is to do with resolution. Traditional red and green have been difficult to mimic on screen. With a quantum dot display, you get richer reds, more vibrant greens (Fig. 1). So a sunset will look all the more spectacular; the golfing green during the Masters more life-like. With quantum dots, you’re not mixing a bunch of colors together to replicate the red of a rose; you’re getting a pure red. Today, when you talk about color gamut—the entire range of colors available on any device—it’s mostly in the range of 70 to 80% of the National Television System Committee (NTSC) color triangle. With quantum dots, you get 100%.

Wong: Why is the color-gamut so important to the visual experience and are there any trade-offs when you increase it?

This file type includes high resolution graphics and schematics when applicable.

Edelman: That’s a great question. Color gamut is important because it describes achievable saturation levels. A wider gamut means you’re closer to matching color according to how the eye sees it, so that things appear more real on screen. Today, the gamut is about 72%, so that means red will look closer to orange. At 100% gamut, you’ll see a true, correct red. The tradeoffs occur in brightness. For example, when you achieve a better red, you also have less of the light coming through to which the eye is sensitive. So, while the color is accurate, you lose the brightness. The great news is quantum dots offer a work around to the problem. One of the many benefits of the technology is that they allow for more light to pass through the color filter so that brightness isn’t sacrificed when achieving color purity (Fig. 2).

Wong: We read that Nanoco uses cadmium-free quantum dots. What are the benefits?

Edelman: The truth is, not all quantum dots are created equal. To date, the few quantum-dot products seeding the market have used cadmium-based quantum dots. Cadmium is a heavy metal and its use is restricted under European and other environmental legislation due to the threat it presents to both human health and the environment. We believe that cadmium has hindered the adoption of quantum dots in devices, keeping display manufacturers from realizing the technology’s benefits and products out of consumers’ hands. We offer a sounder option for manufacturers, giving them all of the color benefit associated with the technology, without the risks associated with toxicity or potential regulatory limitations. Here’s something most people don’t know about Nanoco: We initially set out to produce standard quantum dots, but quickly realized the shortcomings of bringing a technology to market that contains heavy metals. We made an important decision years ago to adjust our strategy and change the direction of the business.

Wong: What are the biggest distinctions between quantum-dot display and OLED display, and what advantages do QDs have?

Edelman: The big distinction is that quantum dots are easy for display manufacturers to adopt. Unlike OLED, which requires a complete and expensive overhaul of a manufacturer’s production line, quantum dots take advantage of the existing LCD infrastructure. That’s a tremendous advantage. Manufacturers are always on the hunt for innovative new technologies to bring to consumers—if you can help them do that without having to re-create the wheel, that’s a great thing. OLED and QD Display offer exceptional color but we’re able to do it without exceptional expense or complexity.

Wong: What are the challenges when designing and manufacturing a display using such a sophisticated and nuanced technology like nanoparticles?

Edelman: You’d think there would be challenges, but we make it easy. We’ve been perfecting the technology for more than a decade so that it’s easy to scale and it’s familiar. We’ve figured out how to add quantum dots to a standard film component, meaning manufacturers already know how to work with it. Those are two big challenges and we’ve cleared them. Cadmium-free quantum dots at scale, delivered in a format that our customers already know how to work with.

Wong: Are quantum-dot displays cost-effective compared to standard offerings/technologies?

Edelman: Absolutely, especially when you compare them to other wide-gamut approaches like OLED. I think it’s fair to say that most manufacturers will see quantum-dot display as a premium offering, whether it’s a premium phone, tablet, or television. And that, initially, is where the adoption will be, with 4K television being a great example. But, like anything in technology, it will trickle down and you’ll see it at various price points.

Wong: Is the technology applicable to all sizes—from large HDTVs to smaller devices?

Edelman: Yes, another of its benefits is its flexible nature. Any screen, any device; color easily tuned to any color space the customer wants. The future is, no doubt, a colorful one.

Dr. Michael Edelman joined Nanoco in 2004, when it was still associated with the University of Manchester. He led the way for initial fund-raising that gaves Nanoco the resources to formally spin out of U of M in June 2005. Prior to Nanoco, he held a number of executive roles including responsibility for licensing the technology developed by GE/Bayer joint venture Exatec LLP, vice president and managing director at yet2.com, commercial director at Colloids Ltd., and business manager at Brunner Mond & Co. Ltd. Edelman, who started his career with ICI, holds a PhD in organo-metallic chemistry from the University of Sussex, UK, and undergraduate degree in classics and chemistry from Tufts University, Boston, Mass.