11 Myths About Embedded FPGAs

Download this article in PDF format.

1. Embedded FPGAs must be expensive.

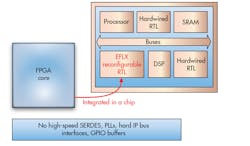

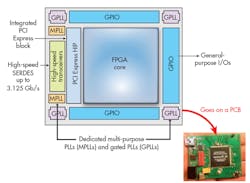

An embedded FPGA is similar to an FPGA chip, but simpler and cheaper. An FPGA chip has 30% or more of its area consumed by the SerDes, PHYs, PLLs, etc., which aren’t needed when integrated into an SoC. FPGA packages, which tend to be large and expensive, disappear when the FPGA is embedded. Furthermore, FPGA chips tend to be “one size fits all” with RAM and DSP blocks, even if you don’t need them, whereas embedded FPGAs can be customized to fit your exact requirements for capacity and options. Think of embedded FPGA in terms of ARM; in other words, compare the cost of the silicon area of your ARM processor versus an Intel processor chip.

2. People who buy from Xilinx and Altera will also need embedded FPGAs.

This is one of the most common misconceptions. The truth is, there is little or no overlap in the customer base. While, most FPGAs are used in low-to-moderate volume systems, embedded FPGAs are intended for high-volume chip companies and companies who design their own ASICs. Some high-volume customers of FPGAs typically shift to ASICs to cut costs. Now with embedded FPGAs, they can shift to ASICs and keep some of their chip flexible.

3. FPGA companies are the logical suppliers of embedded FPGAs.

Just like Intel and AMD have never offered embedded processors, Xilinx and Altera have a business model that’s focused on high-volume, high-margin FPGAs. For years, FPGA companies have been asked if they would supply embedded FPGAs. However, they see it as a small business opportunity that doesn’t make the priority list for their limited engineering resources.

Even today, although ARM has a market capitalization much like that of Intel, it has much lower sales.

The embedded processor business was pioneered by ARM and others (MIPS, ARC, etc.). All of them were startups who could raise enthusiastic venture capital to develop a new market rather than compete with entrenched large chip companies.

4. Embedded FPGAs must be high power.

Most of the power in an embedded FPGA chip is consumed by the SerDes, PHYs, and PLLs, which aren’t in an embedded FPGA.

FPGA chips tend to be optimized for performance; Xilinx and Altera are among the first chip companies developing in the most advanced nodes, such as 7 nm. In contrast, embedded FPGAs can be tuned for different market segments. There are embedded FPGAs optimized for wide programmable control logic in flip-flop (FF) nodes running over 1 GHz. But, there are also embedded FPGAs optimized for low-power 40-nm nodes with multiple power-management modes and sleep/state retention modes down to 0.5V!

5. Embedded FPGAs must be slow.

As explained in Myth #4, embedded FPGAs can be optimized differently for every process node. In 16FF, performance of 500 MHz to over 1 GHz is possible. FPGA is programmable logic, which adds delay while giving flexibility. However, clock rates can be kept high by using the flip-flops available on the output of every programmable logic block to pipeline the logic more than similar hardwired designs.

6. Embedded FPGAs must use a LOT of metal layers.

FPGA chips typically use the maximum number of metal layers available in a process. However, among all suppliers of embedded FPGAs, only Flex Logix uses five or six layers of metal. This increases their compatibility with the wide variety of metal stacks without any process waivers, making them compatible with the minimum metal stacks used for the most cost-sensitive products (e.g., solid-state-disk controllers).

7. Embedded FPGAs only make sense for advanced process nodes.

It’s true that the expense of taping chips at 40 nm and below is making companies think about how they can leverage each tapeout to service more customers and market sub-segments. But the real cost of any chip is the lost opportunities when a market window is missed. Even taping out a chip at 90 nm or 110 nm will take a year for production. Having embedded FPGAs means semiconductor companies can make changes to their chips in days, not quarters, to meet a customer’s market window.

8. Software tools for embedded FPGAs are weak or are non-existent.

FPGA companies have failed because their software tools were immature and lacking. Many of the initial issues they faced were due to developing the entire toolchain. Today, available third-party synthesis tools can be leveraged by embedded FPGA companies to more efficiently spend their engineering excellence on what matters: Making sure the design is compiled to maximize performance and resource utilization, and it’s done quickly.

9. Embedded FPGA technology is brand new.

Actually, it turns out many have tried it before, going back as far as the mid 1990s. Examples include Actel, IBM, LSI Logic, Leopard Logic, and many more. Why these early pioneers weren’t successful isn’t clear, but perhaps mixing an IP business model with a chip business model didn’t make sense. Or, perhaps the density was poor or the IP was from their FPGA design and not with the architecture or process needed by the customers. Another reason could have been that there were too many metal layers. Whatever the challenges, it’s clear that with today’s high mask costs of advanced nodes, embedded FPGAs are here to stay this time.

10. Embedded FPGAs aren’t yet proven?

Companies such as Flex Logix have successfully proven its technology in silicon, so this isn’t just an idea that might work—it does work. Flex Logix has proven its IP in both 40 and 28 nm so far, with 16 nm on the way. Its validation chips prove out all aspects of embedded FPGAs across temperature and voltage to ensure that the IP will work in the customer’s chips. Many customers are working with Flex Logix, but the status is confidential until those customers choose to disclose it (which they may not do even when in production).

11. Embedded FPGAs are nice to have, but not really necessary.

The time and cost to develop chips is growing, so the need to extend life and grow sales is increasing as well. Embedded FPGA can enable one chip to do the work of dozens of metals masks, and speed time to market, by turning variations like serial I/O and encryption into software-programmable versions. Embedded FPGAs can make networking, wireless, and other chips programmable in-system, enabling them to evolve so that they can handle new network, storage, and security protocols. As a result, they more attractive to data centers, and extend the life of the chip design.