Factory Automation Banks on Wireless and AI Technology to Succeed

As more factories become automated, it’s clear that communications between machines, robots, and the computers that direct them is critical. The more information that’s communicated, the greater the productivity. But with ever-larger amounts of data being communicated, the need to analyze and interpret the information, and use it in decision-making, becomes that much more critical. Integration of wireless sensor networks and artificial intelligence (AI) helps meet those demands.

Industrial Internet of Things (IIoT)

The ultimate solution, of course, is the industrial internet of things or IIoT. This is the application of standard IoT concepts to manufacturing. IIoT is essentially the monitoring and control of factory equipment using wireless methods, internet cloud connectivity, and advanced data analysis incorporating artificial intelligence. You may also know of this as Industry 4.0, the German reference to the current fourth generation of manufacturing that incorporates better communications and intelligent computers and software to greatly improve manufacturing through automation.

IIoT advocates connecting all possible devices with sensors to a network that’s able to send the data to computers that can store, analyze and display the data. Software will analyze the data and harvest the knowledge it contains to help make smart decisions that will succeed in achieving the productivity objectives previously set.

Virtually every employee, tool, robot, or device contains valuable data that can potentially improve your manufacturing operations. Such data will identify inefficiencies, spot potential problems, and provide improved quality control. The outcome could produce a competitive edge. An IIoT system can also spot trends, help streamline the manufacturing process, avoid downtime, and optimize your existing assets. The whole approach involves new hardware and software.

Wireless Factory Communications

In the past, wired communications was the norm in factory automation. Many special networks and fieldbuses were created to connect sensors and controlled devices to computers and one another. Many of these networks are still used. In addition, Ethernet has emerged as THE networking technology of choice for industrial applications, sometimes replacing older legacy technologies.

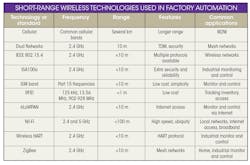

Furthermore, wireless technology has become more reliable with many flexible choices. Thus, it’s emerging as a way to not only replace older systems, but also to increase the amount of sensor monitoring, further increasing the breadth of useful machine data. Below is a rundown of some choices to consider when looking to expand the communications capabilities for a factory automation system (see table).

IEEE 802.15.4

IEEE 802.15.4 is designed to support peer-to-peer links as well as wireless sensor networks. The standard defines the basic physical layer (PHY), including frequency range, modulation, data rates, and frame format, and the media-access-control (MAC) layer. Separate protocol stacks are then designed to use the basic PHY and MAC. Several wireless standards use the 802.15.4 standard as the PHY/MAC base, including ISA100a, Wireless HART, ZigBee, and 6LoWPAN.

The standard defines three basic frequency ranges. The most widely used is the worldwide 2.4-GHz ISM band (16 channels), which has a basic data rate is 250 kb/s. Another range is the 902- to 928-MHz ISM band in the U.S. (10 channels). The data rate is 40 or 250 kb/s. Then there’s the European 868-MHz band (one channel) with a data rate of 20 kb/s.

All three ranges use direct sequence spread spectrum (DSSS) with either binary phase-shift-keying (BPSK) or offset quadrature phase-shift-keying (QPSK) modulation. The multiple-access mode is carrier sense multiple access with collision avoidance (CSMA-CA). The minimum defined power levels are –3 dBm (0.5 mW). The most common power level is 0 dBm, while a 20-dBm level is defined for longer-range applications. Typical range is less than 10 meters.

6LoWPAN

Developed by the Internet Engineering Task Force (ITEF), 6LoWPAN provides a way to transmit IPv6 and IPv4 Internet Protocols over low-power wireless point-to-point (P2P) links and mesh networks. The 6LoWPAN standard (RFC4944), which is short for IPv6 protocol over low-power wireless PANs, also permits the implementation of the Internet of Things on even the smallest and remote devices.

The protocol provides encapsulation and header compression routines for use with 802.15.4 radios. If your wireless device must have an internet connection, this is your technology of choice.

Cellular

With services from most network carriers, cellular radio provides data-transmission capability for machine-to-machine (M2M) applications. M2M is used for remote monitoring and control. Cellular radio modules are widely available to build into other equipment. Older 2G and 3G modules are now being replaced by 4G LTE modules such as NB-IoT. The working range is from 1 to 10 km, which is the range of most cell sites today.

Dust Networks

Dust Networks was acquired by Linear Technology, which in turn was acquired by Analog Devices. Its SmartMesh technology is based on the 802.15.4 and 6LoWPAN standards. The prime benefit of this technology is its ability to form ad hoc, self-repairing mesh sensor networks that increase range and reliability. Other key features are its 10,000-hour battery-lifetime modules and NIST-grade AES-128 security.

SmartMesh networks communicate using a time-synchronized channel-hopping (TSCH) link layer, a technique whereby all nodes are synchronized to within a few microseconds. Network communication is organized into TDM time slots that permit channel hopping and full path diversity. They also offer a version of a HART wired network called WirelessHART (see below).

ISA100a

Developed by the International Society of Automation, ISA100a is designed for industrial process control and factory automation. It uses the 802.15.4 PHY and MAC, but adds special features for security, reliability, feedback control, and other industrial requirements.

ISM Band

Most of these standards use the unlicensed ISM bands set aside by the Federal Communications Commission (FCC) in Part 15 of the Code of Federal Regulations (CFR) 47. The most widely used ISM band is the 2.4- to 2.483-GHz band, which is used by Wi-Fi, Bluetooth, 802.15.4 radios, and many other devices. The second most widely used band is the 902- to 928-MHz band, with 915 MHz being a sweet spot. Modulation is typically ASK/OOK or FSK. Other popular ISM frequencies are 315 MHz for garage-door openers and remote-keyless-entry (RKE) applications, and 433 MHz for remote temperature monitoring.

RFID

Radio-frequency identification (RFID) is used primarily for identification, location, tracking, and inventory. A nearby reader unit transmits a high-power RF signal to power passive (unpowered) tags and then read the data stored in their memory.

RFID tags are small, flat, and cheap, and can be attached to anything that must be tracked or identified. They have replaced bar codes in some applications. RFID uses the 13.56-MHz ISM frequency, but other frequencies are also used, including 125 kHz, 134.5 kHz, and frequencies in the 902- to 928-MHz range. Multiple ISO/IEC standards exist.

Wi-Fi

Wi-Fi is the commercial name of the wireless technology defined by the IEEE 802.11 standards. Next to Bluetooth, Wi-Fi is by far the most widespread wireless technology. It’s in smartphones, laptops, tablets, and ultrabooks, as well as TV sets, video accessories, and home wireless routers. On top of that, it’s deployed in many industrial applications. Wi-Fi is now showing up in cellular networks, where carriers are using it to offload some data traffic like video that clogs the network.

The initial version, called 802.11b, was popular because it offered up to 11-Mb/s data rates in the 2.4-GHz ISM band. Since then, new standards have been developed including 802.11a (5-GHz band), 802.11g, and 802.11n using OFDM to get speeds up to 54 and 300 Mb/s under the most favorable conditions.

More recent standards include 802.11ac, which uses multiple input, multiple output (MIMO) to deliver up to 3 Gb/s in the 5-GHz ISM band. Wi-Fi is readily available in chip form or as complete drop-in modules. The range is up to 100 meters under the best line-of-sight conditions. This is a great option, where longer range and high speeds are needed for the application.

Wireless HART

HART is the Highway Addressable Remote Transducer protocol, a wired networking technology widely used in industry for sensor and actuator monitoring and control. Wireless HART is the wireless version of this standard. The base of it is the 802.15.4 standard in the 2.4-GHz band. The HART protocol is a software application on wireless transceivers.

ZigBee

Emanating from the ZigBee Alliance, this software protocol and technology uses the 802.15.4 transceiver as a base. It provides a complete protocol stack designed to implement multiple types of radio networks that include point-to-point, tree, star, and point-to-multipoint. Its main feature is the ability to build large mesh networks for sensor monitoring. And, it can handle up to 65,000 nodes.

ZigBee also provides profiles or software routines that implement specific applications for consumer home automation, building automation, and industrial control. Examples include building automation for lighting and HVAC control, as well as smart meters that implement home-area-network connections in automated electric meters. ZigBee is widely used in factory automation and can be used in other M2M and Internet of Things applications as well.

Critical Design Factors

The performance of a wireless link is based on pure physics as modified by practical considerations. In implementing a short-range wireless product or system, the important factors to consider are range, transmit power, antenna gains if any, frequency or wavelength, and receiver sensitivity. Basic guidelines include:

• Lower frequencies extend the range if all other factors are the same. This is strictly physics. A 900-MHz signal will travel farther than a 2.4-GHz signal, and a 60-GHz signal has substantially less range than a 5-GHz signal.

• Lower data rates will also extend the range and reliability for a given set of factors. Lower data rates are less susceptible to noise and interference. Always use the lowest possible data rate for the best results.

• Latency is a major factor today in many automation scenarios. Latency is that time delay between the initial trigger of an event and the actual start time of the event. Robot operations are sometimes critical of timing. Latency is usually in the millisecond range, but varies with the technology used. Check your needs before choosing a technology.

• Security may be important if the company fears outside tapping into valuable production data available via wireless. Most wireless products today incorporate security in the form of AES-128 encryption that’s sufficient to protect most systems.

• Losses through walls, surrounding equipment, or other obstacles should also be considered.

• Add fade margin to your design to overcome unexpected environmental conditions, noise, or interference. This ensures your system will have sufficient signal strength over the range to compensate for unknowns. Increase fade margin if the signal must pass through walls and other obstructions.

Keep in mind that antennas can have gain. By making the antenna directional, its beam is more focused with RF power and the effect is the same as raising the transmit power. Half-wave dipoles and quarter-wave verticals aren’t considered to have gain unless compared to a pure isotropic source.

Artificial Intelligence (AI)

What good is added sensor data if you can’t interpret it or use it to boost efficiency? Data-acquisition software can help sort the data and graph it for interpretation. That is positive, but often engineers discover that specialized software is needed for the specific processes involved. As more experience is gained, engineers are finding that AI software can help do more in less time and with minimal injection of human decision-making operations. AI can quickly analyze data and implement process changes to boost productivity on the fly.

One example of an AI application is predictive maintenance. This is the practice of being able to determine what parts might fail in each machine tool and schedule replacement during regular scheduled shutdowns. This prevents unexpected failures that occur during regular production runs and shuts all or many parts of the factory. Unscheduled failures cost massive amounts of money in lost output.

AI software can be built to use regular maintenance data in a knowledge base that records parts replaced in each machine and other factors such as time between breakdowns and other critical data. The AI software analyzes all of these factors and then decides what to replace or service next during a regular maintenance period. This process of predictive maintenance can boost uptime and save thousands if not millions of dollars in lost productivity.

Such AI software needs to be custom-designed in most cases. In some situations, machine learning with neural networks can be used to learn from past maintenance data about what can go wrong and with what frequency.

While the details of AI are beyond the scope of this article, the ultimate goal of AI is to bring a degree of human intelligence to the application, intelligence that can assess a situation and take action. The idea is to analyze raw data and derive knowledge and understanding from it. Then the result is used to solve problems or make decisions. AI is a combination of hardware and special software that exploits search, logic, probability, and other special techniques like neural networks to work its human-like magic.

About the Author

Lou Frenzel

Technical Contributing Editor

Lou Frenzel is a Contributing Technology Editor for Electronic Design Magazine where he writes articles and the blog Communique and other online material on the wireless, networking, and communications sectors. Lou interviews executives and engineers, attends conferences, and researches multiple areas. Lou has been writing in some capacity for ED since 2000.

Lou has 25+ years experience in the electronics industry as an engineer and manager. He has held VP level positions with Heathkit, McGraw Hill, and has 9 years of college teaching experience. Lou holds a bachelor’s degree from the University of Houston and a master’s degree from the University of Maryland. He is author of 28 books on computer and electronic subjects and lives in Bulverde, TX with his wife Joan. His website is www.loufrenzel.com.