Vinduino: An Open-Source, Affordable Water-Saving Technology

Download this article in PDF format.

Approximately 70% of the world’s available drinking water is used by agriculture. Therefore, it makes total sense to consider technology options for optimizing agricultural water use.

Irrigation-management technologies have been around for some time, but only as proprietary systems, meaning that a farmer using such a system is locked into his supplier. Usually this means high cost, recurring fees, and use of older technology, since there’s no incentive for the supplier to innovate. Most commercially available systems are only economically feasible for large farms, leaving smaller growers without options to improve their water use.

Open-Source Hardware and Software

Leveraging on other open-source projects and freely available software-development tools, the Vinduino project uses widely available platforms, like Arduino, Raspberry Pi, and the ThingSpeak website, that are well-documented, low cost, and can be modified by yourself.

The Vinduino project developed a calibrated, low-cost soil-moisture sensor, based on WWII gypsum block technology. Now, more sensors can be used to provide more granular soil-moisture data, while keeping it an affordable solution for small growers. Given our focus on farmers, the offered solution is rugged, easy to install, and easy to use.

Vinduino Project

The idea for the Vinduino project came from the need to better manage irrigation at the Van der Lee vineyard, a four-planted-acre vineyard in Temecula, Calif.

The Temecula wine region is located in Southern California, between San Diego and Los Angeles. There are about 35 wineries in Temecula, receiving 1.3 million visitors annually.

The original version was a handheld soil-moisture reader that had to be taken through the vineyard and connect to gypsum soil-moisture sensors to read the local soil-moisture levels. The Vinduino project was awarded 2015 “Best Product” at the Hackaday Prize, an open-source engineering competition with more than 900 entries from all over the world.

Irrigation Approach

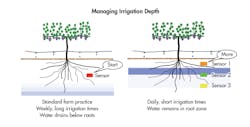

The current irrigation practice for vineyards, the way it has been done for decades, is long good soak once a week. Long irrigation drains deeply in the soil, whereas short irrigation achieves water staying at higher levels.

Following evapotranspiration data, farmers can effectively irrigate more frequently by targeting the exact amount of water needed.

Based on evapotranspiration (ET) data, available from local weather stations, we can estimate the daily amount of water used. Then we can determine how long you need to irrigate in order to replenish the amount of water lost by plant transpiration and soil evaporation.

If you irrigate once a week, and replace the weekly amount of water in one irrigation cycle, you will give more water to the soil than what can be used in one or two days. The surplus of water will drain deeper and eventually become out of reach of the active roots. Unlike popular belief, even for plants with long roots, like grapevines, the actual update of water takes place at shallow soil levels (up to 4 feet).

Together with the draining water, fertilizer will also run off. This will reduce fertilizer efficiency and adds to aquifer pollution.

By irrigating more frequently, like every day, there’s more granular dosage of irrigation water, closely following the (daily) evapotranspiration data. The goal is to supply exactly the amount of water needed and have it delivered only to the soil layers with the active root system, as this is where the plant takes up water.

Moisture Sensors

We have multiple sensors installed in the active root depth to monitor that sufficient water is available to the plants. By placing a soil-moisture sensor below the root zone, we can check how deep the water percolates. By avoiding water draining below the root level, we optimize irrigation for best water quantity and delivery.

By managing irrigation times to stay within the active root zone, all water remains available to the plant, and 25% saving of water use was achieved over two growing seasons.

Soil-moisture sensors, installed in the active root depth, monitor that sufficient water is available to plants. Depth of water percolation can also be checked by placing them below the root zone.

Soil moisture level can be expressed in two ways:

• Volumetric/gravimetric = 0-100% of available water content by volume or weight. Capacitive and TDR-type soil-moisture sensors provide a volumetric reading.

• Soil water tension = energy needed to extract water from the soil, usually expressed in centibars or kPa. Tensiometers and resistive sensors like gypsum block and Watermark sensors provide a soil water tension reading.

Gravimetric and volumetric methods are easy to understand and easy to calibrate. For the weight method, you take a sample of soil, weigh it, dry it in an oven, and weigh it again. Totally dry soil is 0% water content. Then saturate with water and weigh again; this is 100%. Now you can determine the gravimetric water content of the soil samples based on the earlier measured weight. Gravimetric and volumetric methods are soil-type-dependent, so you need to adjust your readings to the local soil properties. Here’s an example to illustrate why this is important:

Clay soils are finer-grained than sandy soils, and therefore the capillary forces to retain water are larger in clay. Plants will start to die at a soil tension of ‒150 kPa—at this point, the plant roots can’t overcome the suction force needed to extract more water from the soil.

The ‒150 kPa compares to an estimated 25% available water in clay, but only 5% available water in sand. So from the perspective of a plant, water availability depends on soil tension, which isn’t the same as the volumetric water content.

Points of view differ on which type of sensor is better for irrigation control. However, farmers mostly prefer soil water tension as a guideline for irrigation decisions.

The first generation of resistive soil-moisture sensors was a gypsum block sensor developed by Bouyoucos and Mick in the 1940s as part of government-funded research for improving agricultural efficiency during the Second World War. This basic design, two electrodes cast in a gypsum medium, was used as a low-cost alternative for expensive commercial sensors in the early stage of the Vinduino project. These sensors have held up well for several years in our Temecula vineyard, but their detection range starts at ‒55 kPa, which limits their usefulness to drought-tolerant crops.

A next generation of the Vinduino sensor is in pre-production phase. Calibration tests show full range response, 0-300 kPa, making it useful for all types of crops.

Using LoRa for Agricultural IoT

Based on other growers’ feedback, a wireless version of the Vinduino soil-moisture reader was developed. Initially it was Wi-Fi-based, but the range proved way too limited to cover even our small vineyard.

Using LoRa, a license-free, long-range wireless technology, proved cost-effective and provided sufficient range for most applications. Depending on local conditions, reliable radio links covering more than five miles have been achieved.

A wireless version of the Vinduino soil-moisture reader uses LoRa, a license-free, long-range wireless technology. Reliable radio links covering more than five miles have been achieved.

After evaluation of several LoRa product development kits, we preferred working with Globalsat products. The justification of this choice was based on ease-of-development, having FCC approval, and the completeness of its product range.

LoRa uses a star topology, a setup where up to 300 sensor stations can send their data to a single central gateway that collects and forwards data to the internet. The Vinduino project uses a low-overhead data-transfer protocol, assuming all data arrives, and with plenty of redundancy. It also leverages the forward-error-correction feature of the LoRa hardware.

Multiple gateways can be used in the same coverage area. When two gateways receive and forward an identical message, only the first arriving will be used. This is useful, as we found most farmers prefer to operate their own local network in areas where LoRa coverage is unavailable or spotty. In the Temecula wine region, we therefore installed multiple gateways with overlapping range, whereas in theory, two or three gateways would be sufficient to provide coverage of the whole wine area.

Vinduino Sensor Station

The Vinduino sensor station collects sensor data in the field and wirelessly transmits at a programmed time interval to limit power consumption. For wireless communication, a LoRa module can be plugged in for long range. We achieved a range of six miles when testing in the Temecula wine area. With directional antennas and line-of-sight conditions, it should be possible to achieve much greater distances while staying within the FCC regulations.

The Vinduino sensor station collects sensor data in the field and wirelessly transmits at a programmed time interval to limit power consumption. A LoRa module can be plugged in for long range.

For applications around the house, an ESP8266 Wi-Fi module can be used instead. The Wi-Fi module connects directly to the Internet, saving the need for a gateway.

There are four terminals to connect soil-moisture sensors. Three sensors monitor water levels in the active root zone, and one is to be installed below the root zone. The Vinduino board standard supports added digital temperature/relative-humidity sensors like the DHT22, which provides a 0.5% accurate temperature reading. A built-in power switch delivers power to active sensors, saving power by activating the sensors only when a measurement is taken.

Depending on the type of crop used, different sensors may be considered. For citrus fruit orchards, frost can cause considerable damage, so a temperature sensor can be a useful addition. Checking wind speed with an add-on anemometer before driving the tractor out with the sprayer can save a lot of time. When wind speed is too high, it makes crop spraying ineffective or undesirable for the environment.

The Vinduino station is powered by a solar panel that recharges a small battery to keep the unit activated after dark and during cloudy days. So once installed, it’s virtually maintenance free.

The microcontroller used in a Vinduino station is Arduino-compatible, making it easy to customize the software and support a wide choice of sensors and use cases. For this purpose, the Vinduino station software, as well as its hardware design details, are made available in the public domain.

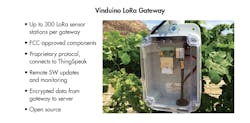

LoRa Gateway

To connect the LoRa sensor stations to the internet, we need a LoRa gateway. For the Vinduino project, we now have a choice of available gateways:

• Commercial: LG-S201H LoRa MOST Gateway

• Open source: Based on Raspberry Pi and Globalsat LD-20 LoRa USB module

With this setup, an open-source gateway can handle up to 300 sensor stations within a range of five miles.

An open-source LoRa gateway for connecting to the internet can handle up to 300 sensor stations within a range of five miles.

The technical installation of the open-source version of the gateway can be limited to downloading and configuring the free Python programming language environment, uploading and installing free Vinduino gateway software, and plugging in the LoRa dongle in the USB port.

Because the software is based on the Python programming language, supported PC platforms that can function as a gateway include Windows, MacOS, Ubuntu Linux, and Raspberry Pi.

Basic data visualization can be obtained for free from ThingSpeak.com. The Vinduino gateway software is standard setup to forward sensor data to ThingSpeak, which provides nice charts of sensor data and has some customization options like time scale and averaging. ThingSpeak stores your sensor data in a database, and you can download your sensor data in a spreadsheet format for local analysis. If you want more, several companies offer DIY dashboard tools based on ThingSpeak. Examples are FreeBoard, and the Highstock Java scripts, free for non-commercial use.

To address the needs of professional users, Vinduino will engage in partnerships with providers of crop-specific dashboards.

The Vinduino wireless network is based on a hardware implementation of the LoRa specification, also called LoRaLAN. This isn’t compatible with public networks operated by LoRaWAN providers like The Things Network, Senet, and Loriot.

Network providers usually prioritize urban coverage over covering rural areas. With LoRaWAN, it’s not any different. Therefore, it will likely be a while before we see good rural coverage with LoRaWAN. Nonetheless, operating your own local LoRaLAN network has proven a very workable solution for several wineries and vineyards that have used the Vinduino system since last year.

Savings Realized

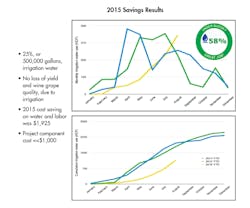

In early 2015, we installed battery-operated irrigation valve controllers as a replacement for manual control of the irrigation. We use the ET data and soil-moisture readings for irrigation decisions.

Based on ET data, we can calculate how many gallons per vine per day are needed. If, for example, the temperatures have been soaring well over 100°F, ET calculation may show that daily water use is four gallons per vine. Every vine has two drippers installed that are designed to deliver 1 gallon/hr. So we set our irrigation timer to two hours to deliver four gallons per vine.

An estimated water saving of 25% was achieved in 2015, the hottest year in recorded history.

With the soil sensor data, we can create a closed-loop system. If the ET estimate was off—after all, it’s an estimate only—we would see an increased or decreasing soil-moisture trend, where it should be maintaining the same moisture level if we replace 100% of the water used. We can now use the soil-moisture trend to correct the irrigation time if our purpose is to maintain the soil moisture.

2015 was the hottest year in recorded history, and as such, a straight comparison with water use from previous years isn’t reliable. Nevertheless, we achieved an estimated water saving of 25% when comparing water use at harvest time, and we saved cost on manual operation of the irrigation by our vineyard management company.

Probably most important is that we have peace of mind knowing that we now have the tools to manage our irrigation without compromising vineyard health or crop yield. After all, crop yield is what pays the bills for a farmer. The initial saving results have proven to be sustainable, and drive us to make the Vinduino project available to the public domain so that it can be taken advantage of by other growers.

Adding Value

Because the Vinduino project deliveries include soil sensors, sensor station, and gateway, there’s ample opportunity to add value by adding customized dashboards and smartphone apps. Future additions can include irrigation actuator control, already supported in the Vinduino hardware, and machine learning for optimizing the irrigation scheduling. Having an open-source system makes it easy for partner developers to customize and add value.

Final Thoughts

The concept of using open-source technologies for making water-saving technology affordable is well received within farming communities.

Vinduino solutions have found their way to several vineyards in the U.S., and to a growing number of overseas countries, including Argentina, Australia, Brazil, Chile, France, Germany, and Tunisia. Application is not limited to wine grapes—coffee beans, orchards, and many other different crops are all possibilities in the near future.

Reinier van der Lee is a weekend wine grower, and serves as Director of Product Marketing at a high-tech semiconductor company in Irvine. He is co-author of 17 issued technology patents. Van der Lee was founder of a wine import company, and has a sommelier certificate.